A modulus ruler for installing metal roof panels

A metal house and modulus technology, applied to roofing, tools for roofing engineering, construction, etc., can solve problems such as deformation, roof leakage, and bracket distortion, and achieve the effects of accurate positioning, high efficiency, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

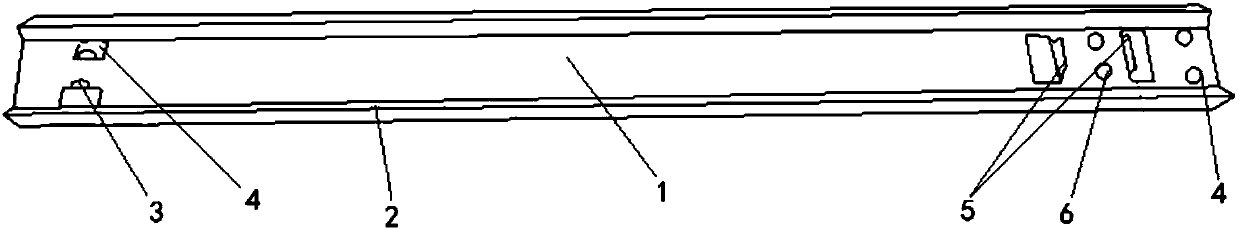

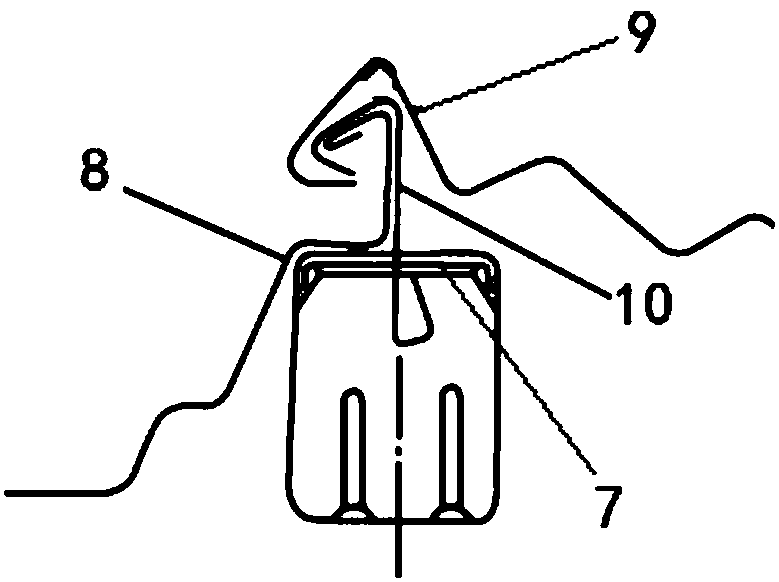

[0024] A modulus ruler for installing metal roof panels, the structure of which is as figure 1 As shown, the modulus ruler is installed on the roof purlins, and includes a horizontal bottom surface 1 and raised edges 2 arranged on both sides of the horizontal ground 1 . One end of the horizontal bottom surface 1 is provided with a mounting hole 4 and a positioning limiting piece 3, the positioning limiting piece 3 is located inside the mounting hole 4 and is parallel to the raised edge 2; the other end of the horizontal bottom surface 1 is provided with a mounting hole 4 outside , a positioning control mechanism 5 is provided inside the mounting hole, and a mounting hole 6 is provided in the middle of the positioning control mechanism 5 . In this embodiment, the positioning control mechanism 5 adopted is a slot hole with a protrusion on the inner surface, and the protrusion is perpendicular to the raised edge 2 .

[0025] When two modular rulers are connected, the positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com