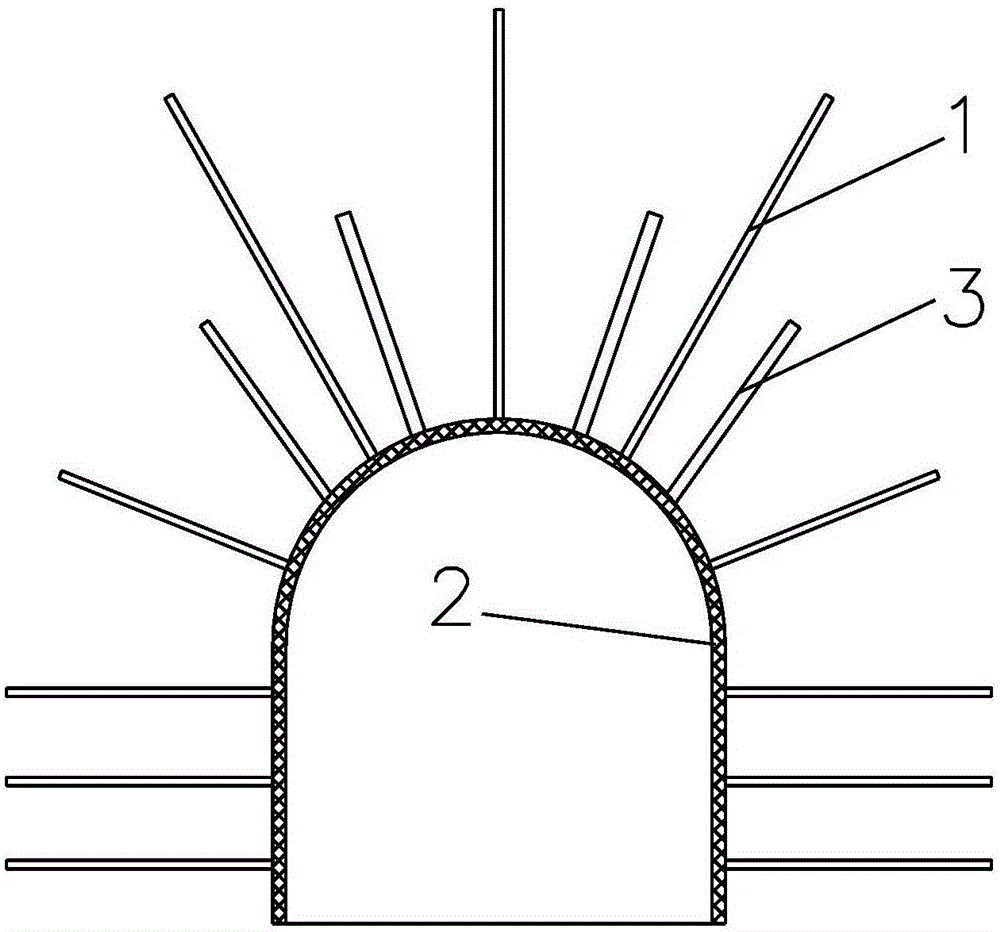

Loose and weak surrounding rock combined bolting and shotcrete structure and construction method

A technology of weak surrounding rock and shotcrete anchor support, applied in tunnels, tunnel lining, bolt installation, etc., can solve problems such as easy collapse and failure of bolts, achieve uniform force, good support effect, and improve support effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

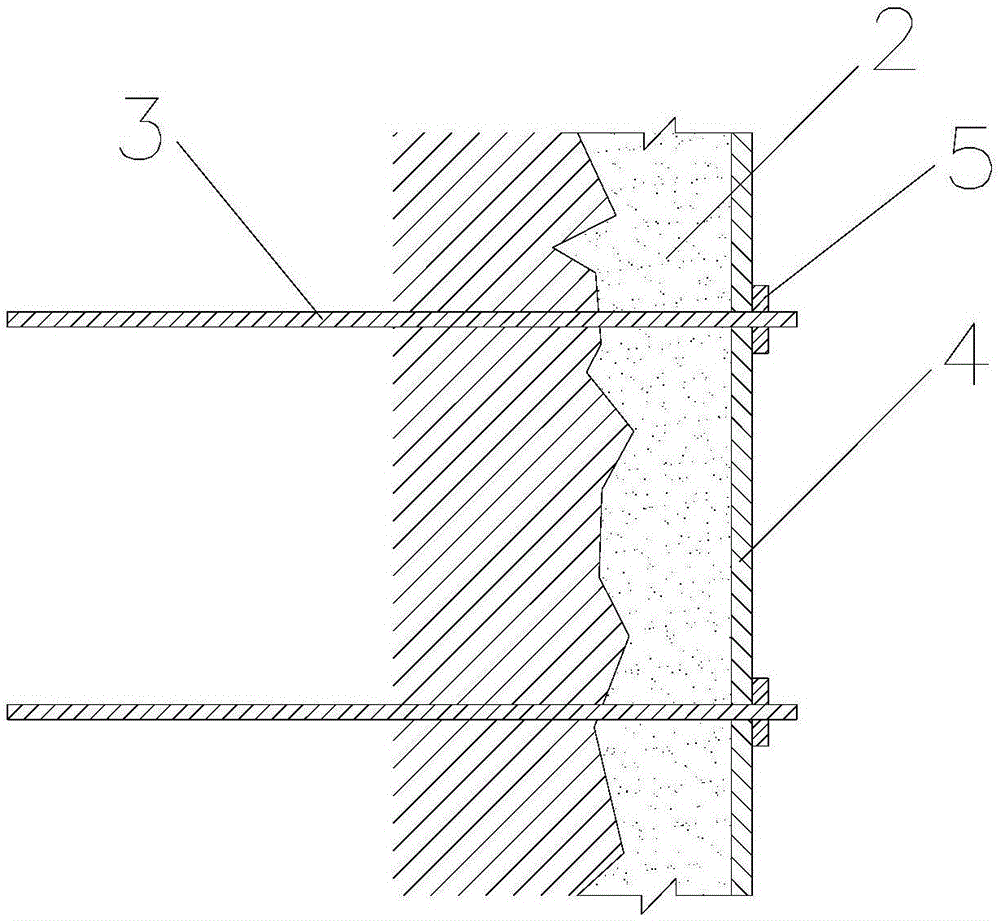

[0021] A construction method for a spray-bolt support structure in a roadway with loose and weak surrounding rocks, comprising the following steps: ① construction and forming of the roadway; ② spraying a flexible spray layer 2 on the surface of the roadway. In this application, polyurethane resin material is used as an example, with a thickness of 30 -80mm, so that the surrounding rock surface of the roadway forms a flexible whole; ③ add a steel belt 4, and construct a high-strength left-handed non-longitudinal rib threaded steel anchor 3, the row spacing is less than 1000 mm, and the deviation is ± 100 mm; the anchor 3 is perpendicular to the rock wall, the deviation is less than 10°, anchor rod 3 is anchored with resin anchoring agent, the anchoring force is not less than 100kN, and the pre-tightening force is not less than 80kN; ④Construction anchor cable 1, anchor cable 1 is anchored with resin anchoring agent, and the anchoring force is not low At 250kN, the pretightening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com