Shell rotating type hydraulic motor flow distributor

A technology of hydraulic motors and distributors, which is applied in the field of hydraulic components, can solve the problems of complex structures and many parts where oil flows through, and achieve the effects of improving production efficiency, simplifying structures, and reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

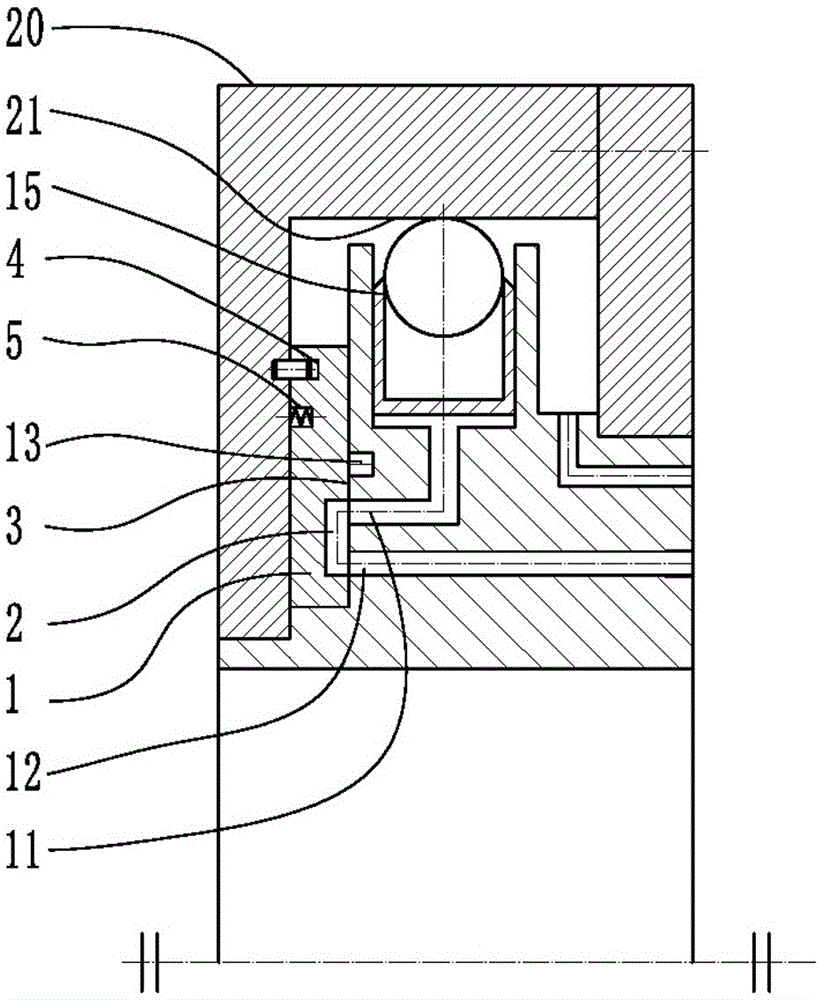

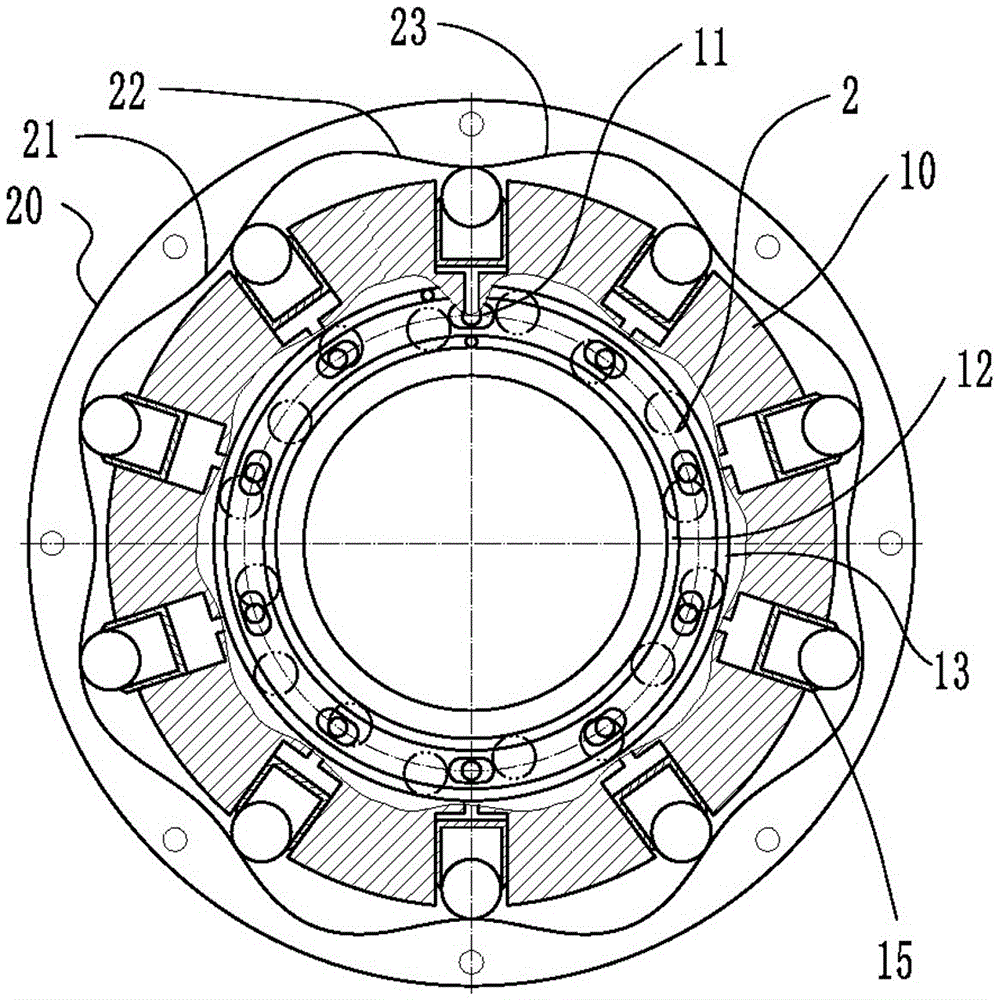

[0027] The flow distributor rotates synchronously with the rotating casing 20. Embodiment 1: The synchronization method is the same as that of the Chinese utility model patent "A Shell Rotating Hydraulic Motor" with the Patent Application No. 201320630992.7 (published No. CN 203627076 U), that is, by positioning The device positions the flow distribution plate and the rotating casing, and controls it to rotate synchronously with the rotating casing. Embodiment 2: The flow distributor and the rotating housing are interference-fitted or welded together.

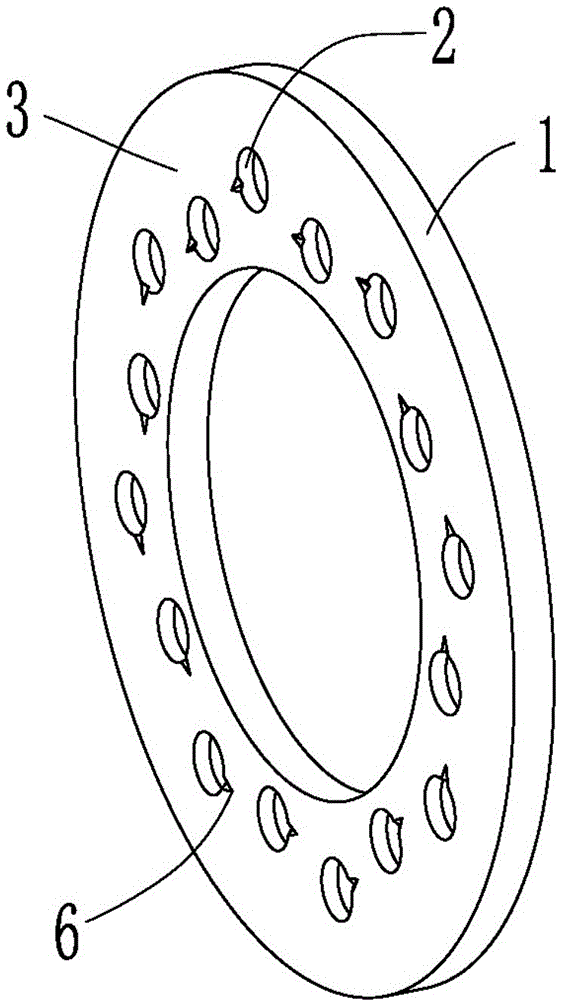

[0028] like image 3 As shown in the figure, the distribution window 2 on the distributor has a positional relationship with the rotating housing 20, and the number of distribution windows 2 on the rotating distribution surface 3 is twice the number of motor functions. The distribution window 2 can communicate with the pressure channel 12 and the plunger hole channel 11 . At the middle position of the plunger retraction curve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com