Pulling bar controlled type dual-linkage freeze-prevention ceramic valve

A ceramic valve and control technology, which is applied in the field of ceramic valves, can solve the problems of frozen cracked valve core, poor sealing performance, stagnant water, etc., and achieve the effects of preventing frost cracked, low production cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings, so that those of ordinary skill in the art can implement it after referring to this specification.

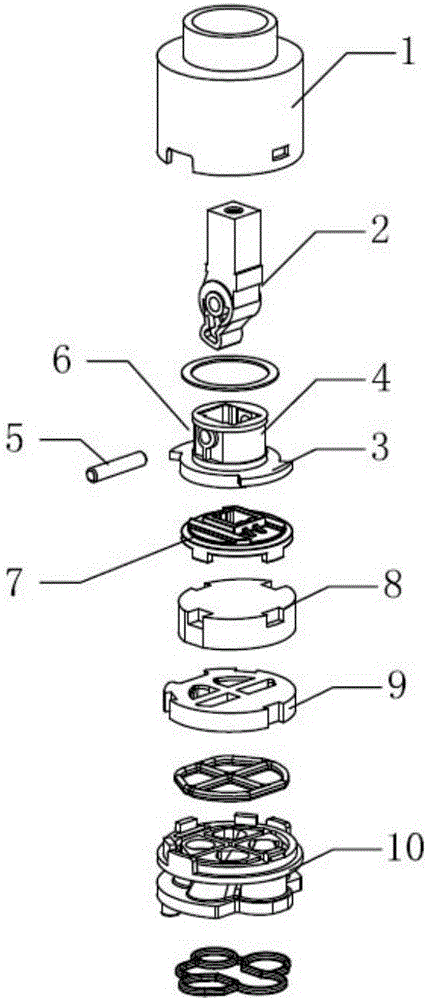

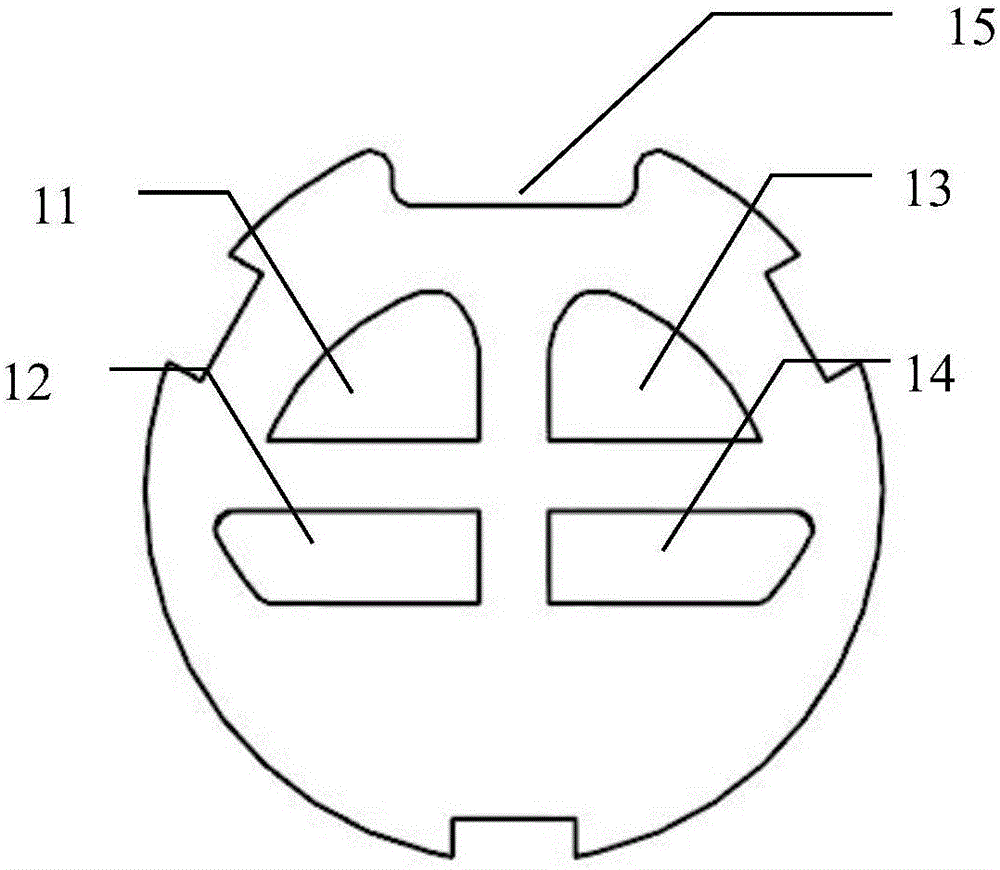

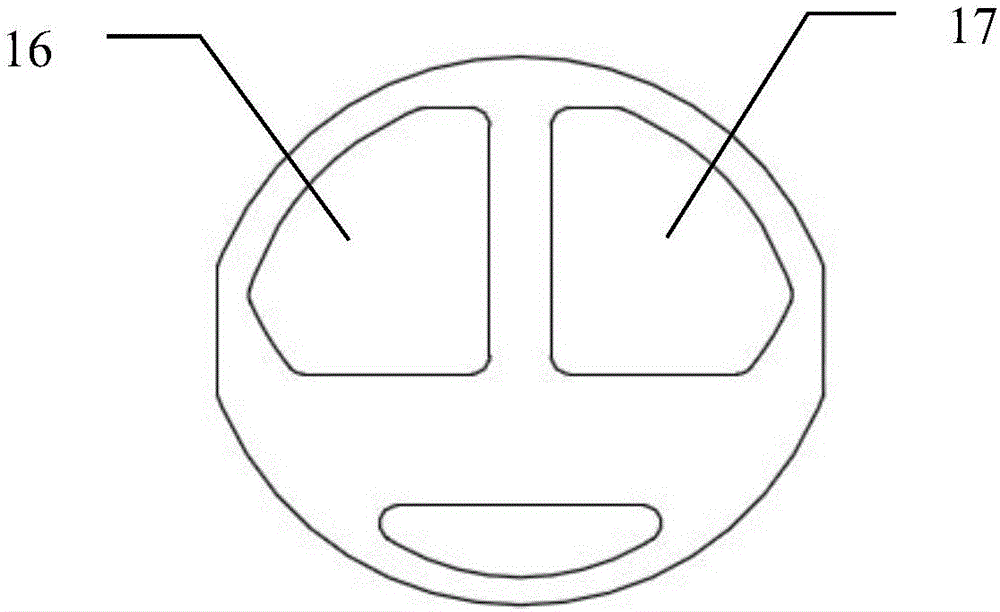

[0032] Such as figure 1 , figure 2 as well as Figure 4 As shown, a pull rod control double-linkage antifreeze ceramic valve, which includes a base 10 with at least four channels on its plane; a control part that is fixed on the upper end of the base 10 and includes a static plate 9 And the moving plate 8, the static plate 9 has five water holes on the plane, which are the cold water inlet hole 11, the cold water outlet hole 12, the hot water inlet hole 13 and the hot water outlet hole 14 respectively communicating with the four channels, And the drainage hole 15 that is not connected with the four passages, a concave cavity is dug on the plane of the moving piece, and the moving piece is covered on the static piece in a slidable manner. According to the relative sli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com