A liquid flow constant control device

A technology of constant control and liquid flow, which is applied in the direction of flow control of auxiliary non-electric power, valve device, valve housing structure, etc., and can solve problems such as change, spring elastic coefficient change, flow instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

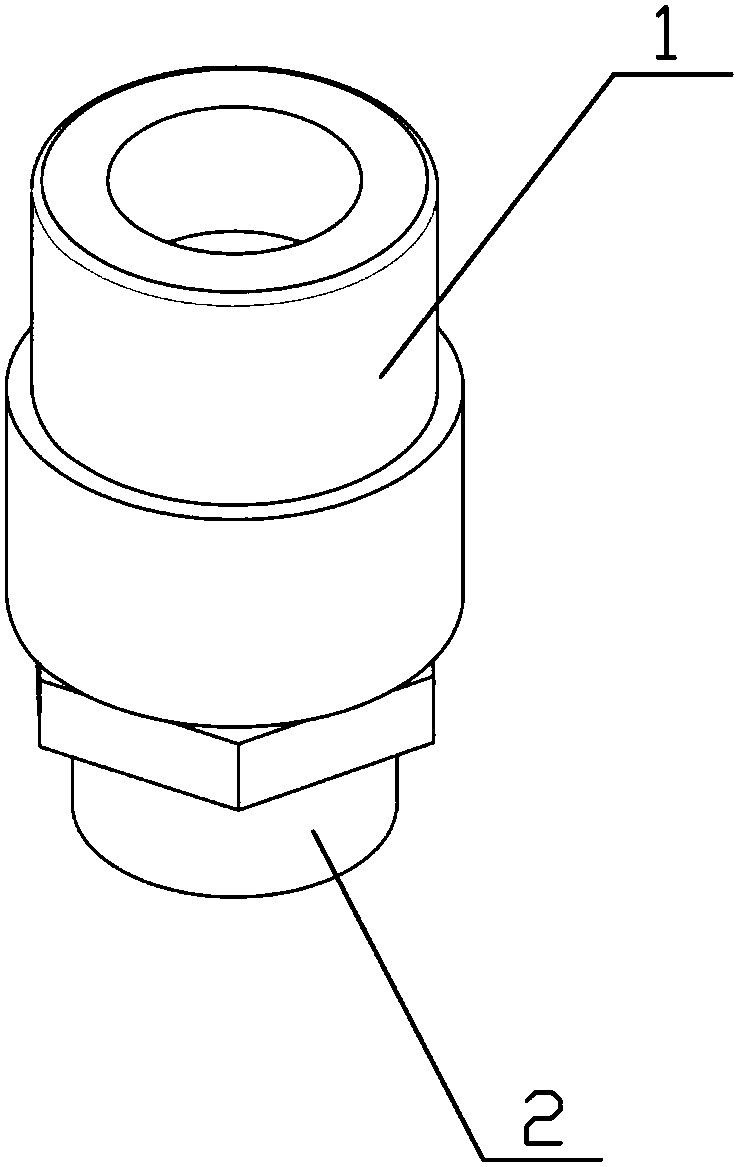

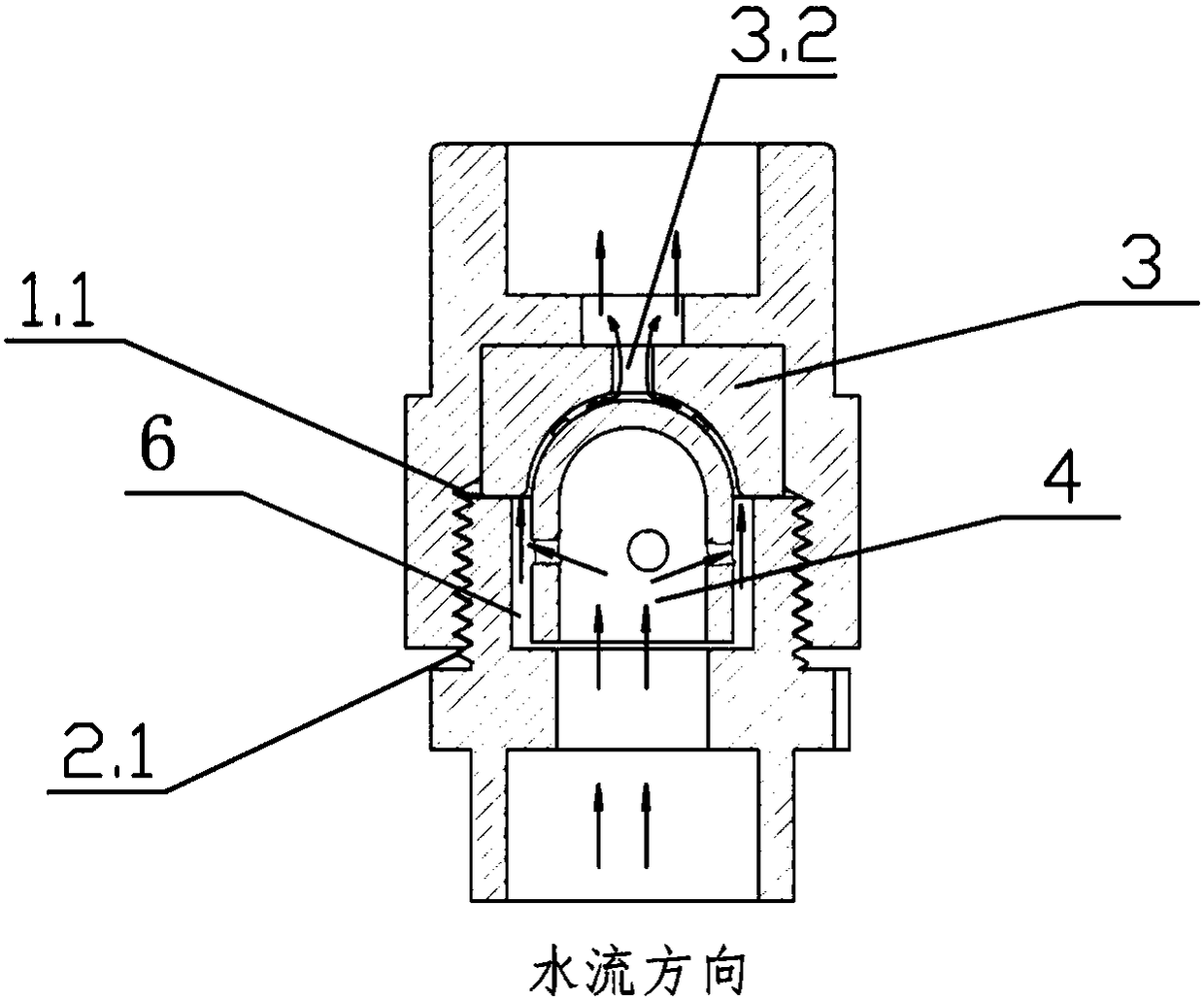

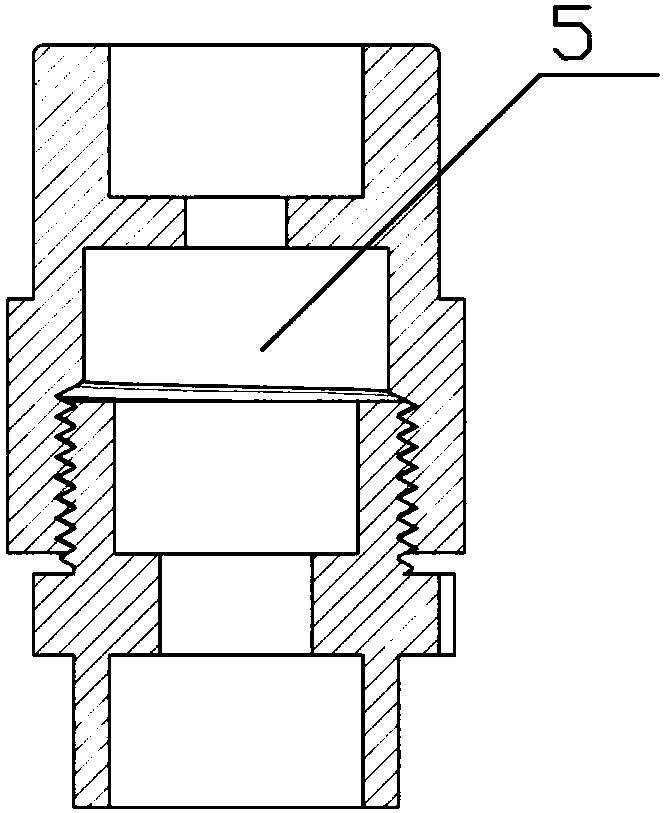

[0032] Example 1. refer to Figure 1-7 . A liquid flow constant control device of the present invention comprises an upper valve body (1), a lower valve body (2), an elastic pad (3) and a movable valve core (4), and the upper valve body (1) is provided with There are internal threads (1.1), and the lower valve body (2) is provided with external threads (2.1) matching with the upper valve body (1), and the upper valve body (1) and the lower valve body (2) are connected by internal and external threads And form the valve body cavity (5) after the upper valve body (1) and the lower valve body (2) are combined, in the valve body cavity (5), along the upper valve body (1) to the lower valve body (2 ) is provided with an elastic pad (3) with a hole and a movable valve core (4) in sequence in the axial direction, and the movable valve core (4) includes a semicircular sealing part (4.1) and a cylindrical The guide part (4.2), the outer surface of the semicircular sealing part (4.1)...

Embodiment 2

[0033]Example 2. refer to Figure 1-7 . A liquid flow constant control device of the present invention comprises an upper valve body (1), a lower valve body (2), an elastic pad (3) and a movable valve core (4), and the upper valve body (1) is provided with There are internal threads (1.1), and the lower valve body (2) is provided with external threads (2.1) matching with the upper valve body (1), and the upper valve body (1) and the lower valve body (2) are connected by internal and external threads And form the valve body cavity (5) after the upper valve body (1) and the lower valve body (2) are combined, in the valve body cavity (5), along the upper valve body (1) to the lower valve body (2 ) is provided with a holed elastic pad (3) and a movable spool (4) in sequence in the axial direction, and the movable spool (4) includes a semicircular sealing part (4.1) and a cylindrical The guide part (4.2), the outer surface of the semicircular sealing part (4.1) is provided with ...

Embodiment 3

[0034] Example 3. refer to Figure 1-7 . A liquid flow constant control device of the present invention comprises an upper valve body (1), a lower valve body (2), an elastic pad (3) and a movable valve core (4), and the upper valve body (1) is provided with There are internal threads (1.1), and the lower valve body (2) is provided with external threads (2.1) matching with the upper valve body (1), and the upper valve body (1) and the lower valve body (2) are connected by internal and external threads And form the valve body cavity (5) after the upper valve body (1) and the lower valve body (2) are combined, in the valve body cavity (5), along the upper valve body (1) to the lower valve body (2 ) is provided with a holed elastic pad (3) and a movable spool (4) in sequence in the axial direction, and the movable spool (4) includes a semicircular sealing part (4.1) and a cylindrical The guide part (4.2), the outer surface of the semicircular sealing part (4.1) is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com