Fusing-type electric heating fusion tube fitting

A fuse-type, electric heating technology, applied in the direction of pipes/pipe joints/fittings, through components, pipe connection layout, etc., can solve problems such as high heat, increased pressure, and inability to respond in time, and achieve the effect of avoiding excessive current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In the following, the substantive features and advantages of the present invention will be further described in combination with examples, but the present invention is not limited to the listed embodiments.

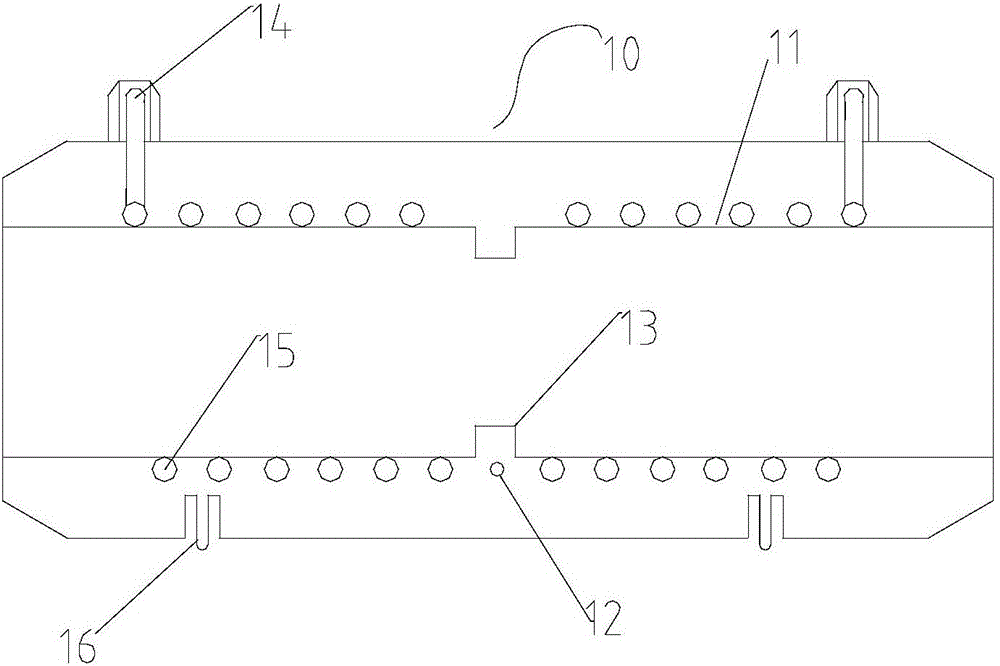

[0012] Such as figure 1 As shown, a fuse type electrothermal fusion pipe includes a tubular body 10, a terminal 14 and an observation post 16 are arranged on the outer wall of the tubular body, and a spirally wound resistance wire is embedded in the wall 11 of the tubular body , The resistance wire is electrically connected to the terminal, the inner wall of the tubular body is provided with a ring-shaped limiting boss 13; the resistance wire includes a first resistance wire 15 and a first resistance wire connected to the first resistance wire Two resistance wires 12, the diameter of the first resistance wire is greater than the diameter of the second resistance wire, the first resistance wire is wound on both sides of the annular limiting boss, and the second resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com