Jun porcelain kiln

A kiln body and Jun porcelain technology, applied in the field of kilns, can solve the problems of affecting the internal structure of the product, insufficient gas combustion, and difficulty in controlling the gas transmission volume, and achieve the effects of easy temperature control, reduced energy consumption, and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

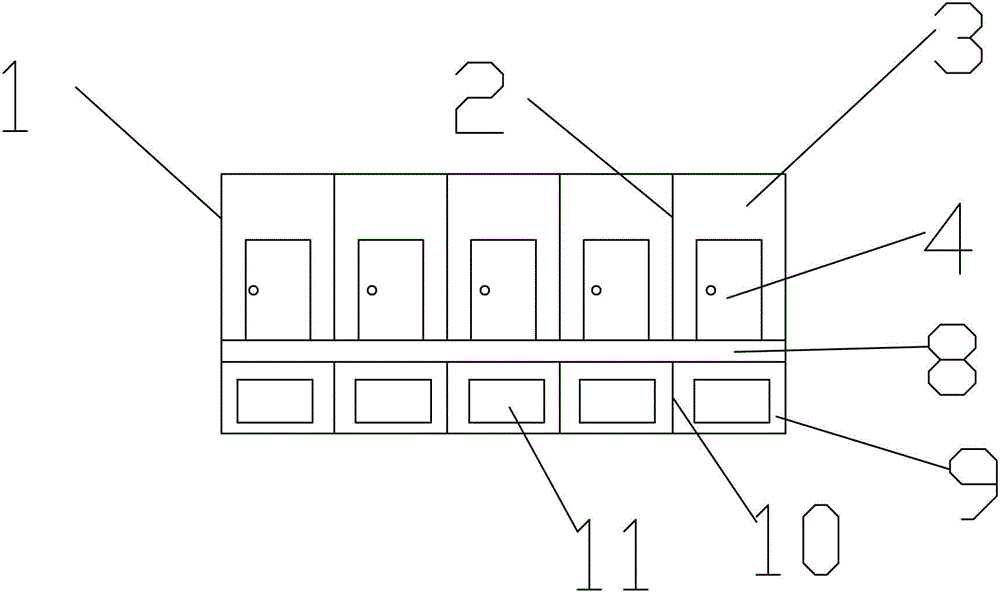

[0016] Such as figure 1 , figure 2 As shown, a Jun porcelain kiln body includes a kiln body 1; a plurality of kiln chambers 3 are arranged on the upper part of the kiln body 1, and a kiln door 4 is movably arranged on one side of each kiln chamber 3, and a combustion chamber 3 The bottom of the flame shield 8 is provided with a plurality of combustion chambers 9, and each combustion chamber 9 is provided with a gas tank 11, and the gas tank 11 passes through the gas pipe and the ignition device at the bottom of the flame barrier 8. connected.

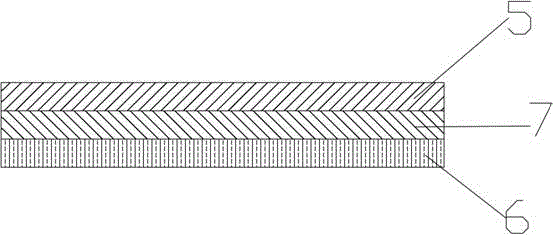

[0017] A partition 2 is arranged between the kiln chambers 3, and a heat-reflecting paint layer is arranged on the partition 2. The inner side of the kiln door 4 has a heat-insulating paint layer, and the heat-insulating paint layer of the kiln door 4 also has a heat-reflecting coating. The kiln main body 1 includes an inner layer 5 , an outer layer 6 and an insulation layer 7 arranged between the inner layer 5 and the outer layer 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com