Vibration amplifier and testing method for simulating high-order nonlinear vibration fatigue of blade

A test method and amplifier technology, applied in the field of material fatigue fracture and high cycle fatigue test, can solve the problems of nonlinear stiffness, unsolved resonance, and small frequency adjustment range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

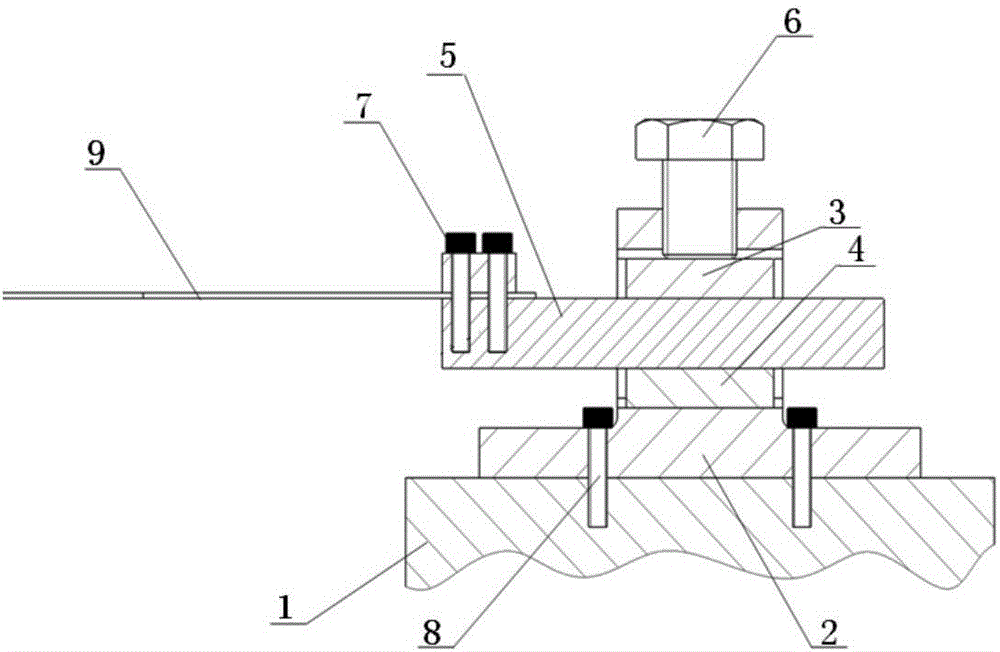

[0037] The present invention is described in further detail below in conjunction with accompanying drawing:

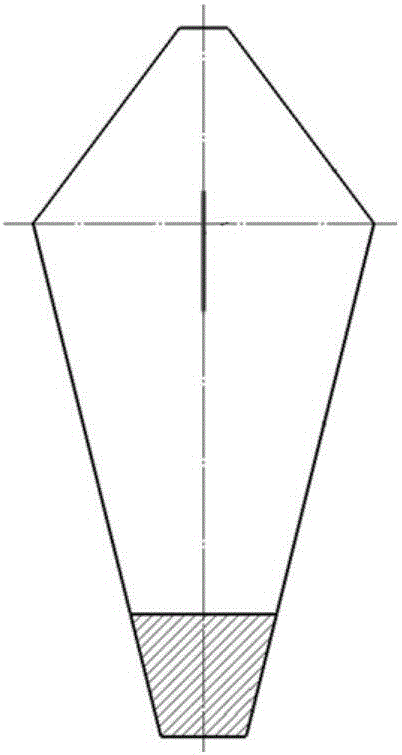

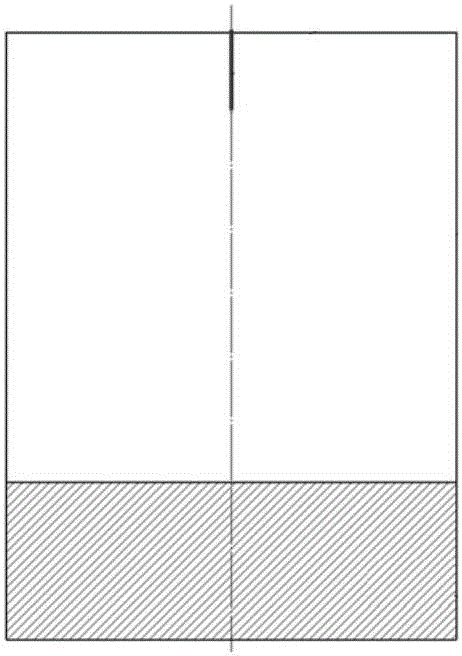

[0038]The vibration amplifier of the present invention includes a base 2, a fixed housing, an upper pad 3, a lower pad 4, a first fixing screw 7, a second fixing screw 6, an amplifying arm 5 and a clamping block 10; an upper pad 3 and the lower pad 4 are located in the fixed housing, and one end of the amplifying arm 5 passes through one side of the fixed housing, between the upper pad 3 and the lower pad 4, and the other side of the fixed housing to extend out to the fixed housing. Outside the housing, the clamping block 10 is located on the upper surface of the other end of the amplifying arm 5, and the first fixing screw 7 passes through the clamping block 10 and the amplifying arm 5 to connect the clamping block 10 with the amplifying arm 5, and the second fixing screw 6 Pass through the top of the fixed housing and extend into the fixed housing to contact the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com