Characterization method of transformer oil aging

A technology for transformer oil and characterization, applied in the direction of material inspection products, can solve problems such as poor accuracy, and achieve the effect of improving monitoring capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

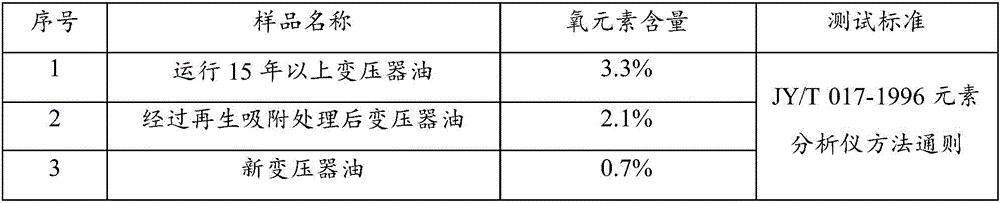

[0066] Actual transformer oil sample analysis experiment:

[0067] The content of oxygen element in the transformer oil that has been in operation for more than 15 years, the transformer oil after regeneration and adsorption treatment and the new transformer oil are respectively measured. The specific steps are as follows:

[0068] Use JY / T017-1996 element analyzer to measure the content of oxygen element in the above three groups of transformer oils according to JY / T017-1996 element analyzer method general rule.

[0069] Among them, the temperature control program is as follows: conduct the first temperature control at 1000°C to 1100°C and keep it for 0.8min to 1.2min; perform the second temperature control at 550°C to 600°C and keep it for 3min to 4min; Temperature control for the third time at ℃~105℃, keep for 10min~15min; the carrier gas is helium; the purity of the carrier gas is ≥99.99%, and the moisture content is ≤10 - 6 g / L; the accuracy of oxygen element analysis i...

Embodiment 2

[0074] Determination of oxygen content in transformer oil:

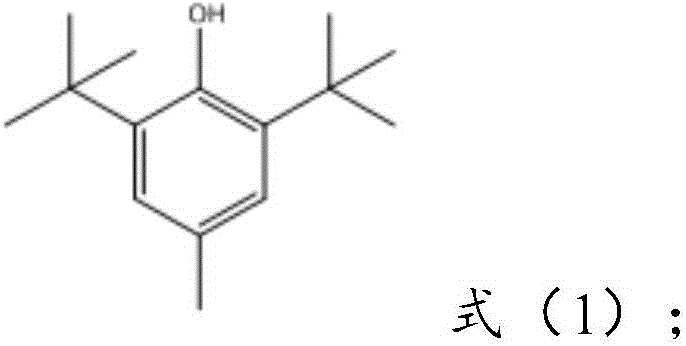

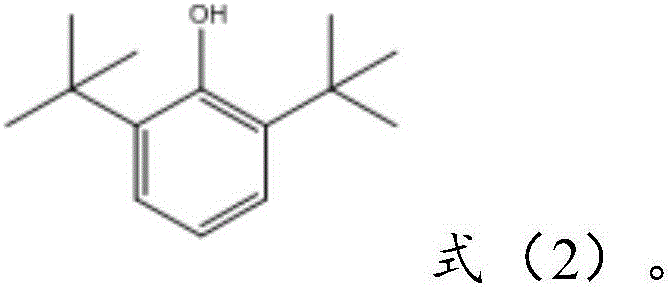

[0075] (1) Perform pretreatment on the transformer oils whose antioxidants in the six groups are 2,6-di-tert-butyl-p-cresol and have been in operation for more than 15 years: take 25mL of the above-mentioned transformer oils accurately, and vacuum-dry them for 3 hours. Get 6 groups of transformer oil to be tested.

[0076] (2) Detect the content of antioxidants in 6 groups of transformer oils to be tested respectively, obtain the content of antioxidants in 6 groups of transformer oils to be tested to be respectively 0.300%, 0.295%, 0.310%, 0.305%, 0.298% and 0.303% ; Then by the formula: oxygen element content in 2,6-di-tert-butyl-p-cresol ×molecular weight of oxygen element / 2,6-di-tert-butyl-p-cresol molecular weight=content of oxygen element in antioxidant in transformer oil 0.022%, 0.021%, 0.023%, 0.022%, 0.022% and 0.022%, respectively.

[0077] (3) Measure the total content of oxygen in 6 groups of transformer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com