Wheel service state safety margin estimation and fault diagnosis method

A service state and fault diagnosis technology, applied in the field of traffic safety engineering, can solve problems such as the inability to provide clear policy guidance for vehicle repair and maintenance, and the inability to give the service state of wheels, etc., to achieve high precision, high stability, and convergence speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

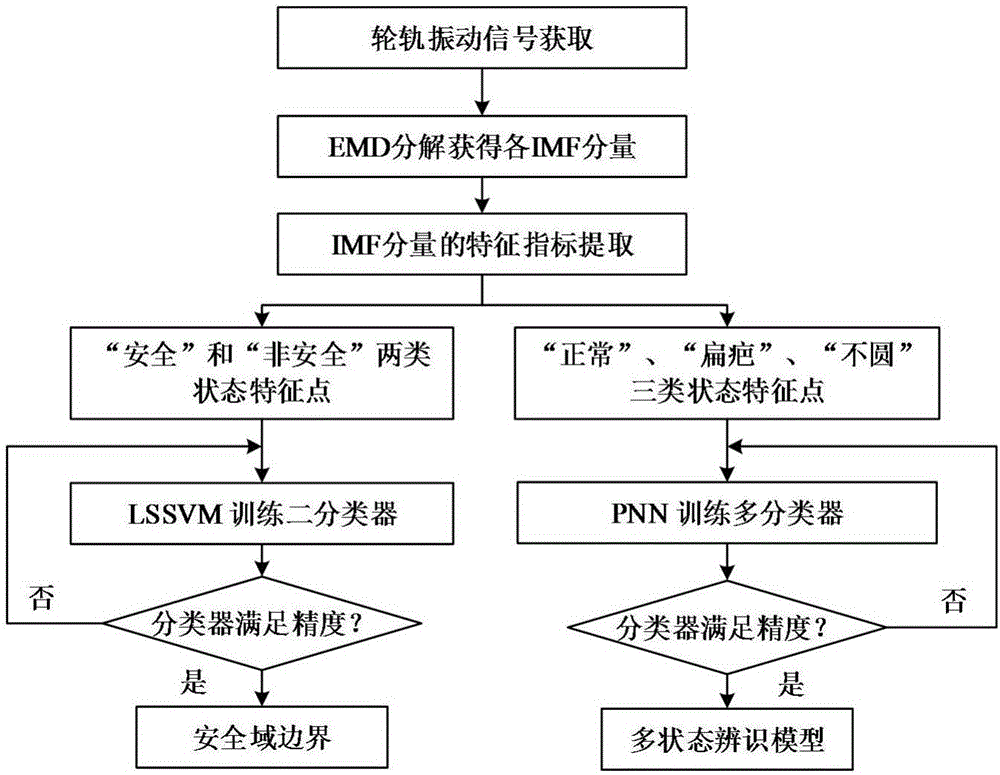

Method used

Image

Examples

Embodiment 1

[0092] Using the vehicle-track vertical coupling dynamics model for simulation, 220 sets of rail vibration signals of normal wheels, 220 sets of rail vibration signals of flat-scar wheels and 220 sets of rail vibration signals of out-of-round wheels are obtained. The vibration signals of each set include 2000 data points. 220 groups of normal wheel signals and 440 groups of faulty wheel signals are decomposed by EMD to obtain each IMF component;

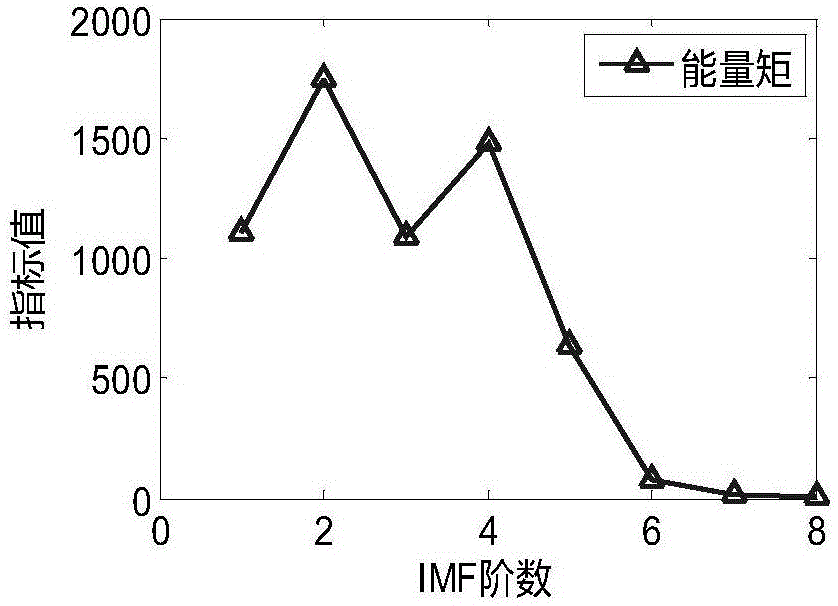

[0093] Calculate the energy moment of each IMF component, and use the calculation result as the state eigenvector of the vibration signal, with figure 2 is the IMF characteristic index value of the normal wheel, since the IMF order decomposed by EMD of each signal is not exactly the same, here we take the least IMF order after decomposing 660 signals as the construction feature vector:

[0094] T=[t 1 t 2 ...t n ]

[0095] In the formula, T is the feature vector constructed by each index, and n is the least IMF order.

[0096]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com