Steam turbine remote intelligent operation and maintenance service system

A service system and steam turbine technology, applied in the field of steam turbine operation and maintenance service system, can solve the problems of inability to realize steam turbine operation and maintenance in a timely and comprehensive manner, and low efficiency, and achieve the effect of comprehensive operation and maintenance measures, high efficiency, and data sharing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

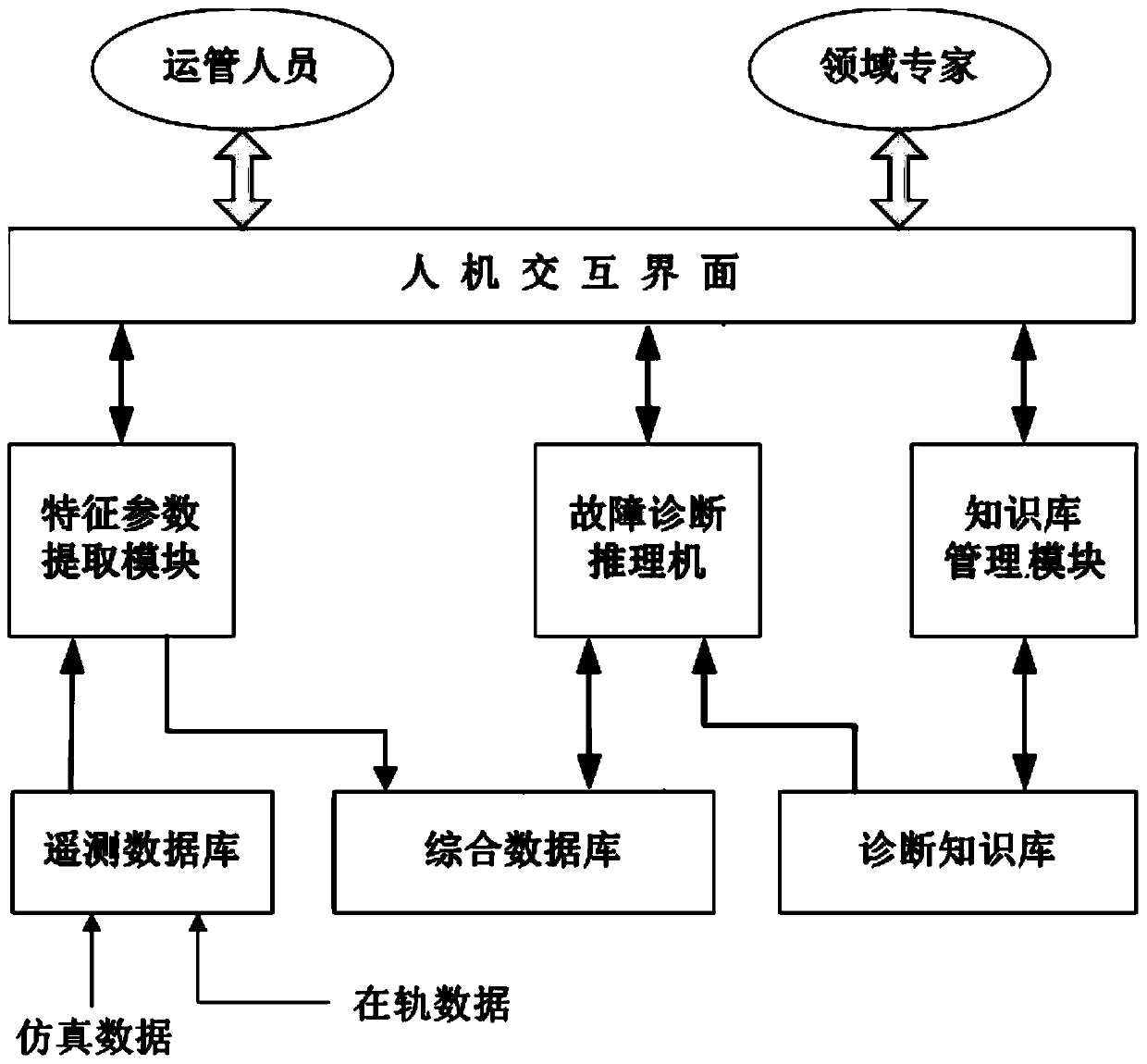

[0029] Specific implementation mode one: combine figure 1 To describe this embodiment,

[0030] The main tasks of the steam turbine remote intelligent operation and maintenance service system are: by analyzing telemetry data or ground test data, extracting characteristic parameters, and judging the fault state of the system; using expert knowledge to reason, determine the fault location, identify the fault mode, and give Corresponding troubleshooting plan.

[0031] This embodiment is a remote intelligent operation and maintenance service system for steam turbines, including: a telemetry database, a comprehensive database, a diagnostic knowledge base, and multiple modules such as a feature parameter extraction module, a diagnostic inference engine, and a knowledge base management module. Its structure is as follows figure 1 shown. The function description of each component of the system is as follows:

[0032] (1) Telemetry database, used to acquire and store telemetry data,...

specific Embodiment approach 2

[0077] This implementation mode is a steam turbine remote intelligent operation and maintenance service system, and the diagnostic reasoning machine also includes:

[0078] Turbine bearing metal temperature is too high fault diagnosis module;

[0079] Low metal temperature fault diagnosis module for steam turbine bearings;

[0080] Fault diagnosis module for excessive temperature difference between the inner wall and the outer wall of the steam turbine;

[0081] Fault diagnosis module for abnormal temperature of steam turbine thrust bearing;

[0082] Fault diagnosis module for abnormal oil pressure of steam turbine lubricating oil pump;

[0083] Turbine pressure setting value (at rated speed) lubricating oil working oil pressure abnormal fault diagnosis module;

[0084] Fault diagnosis module for abnormal oil temperature of steam turbine oil tank;

[0085] Fault diagnosis module for abnormal oil pressure of the jacking shaft oil pump of the steam turbine;

[0086] Low-pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com