Constant current charging-stopping type charger

A charge-stop, charger technology, applied in the electronic field, can solve the problems of damage, increase the overall scrapping of the charger, and the charging tube is easily damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

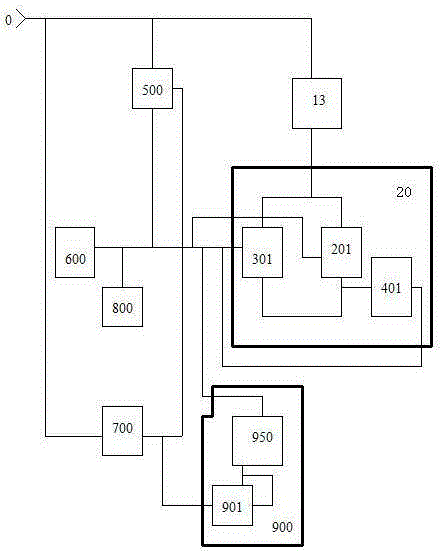

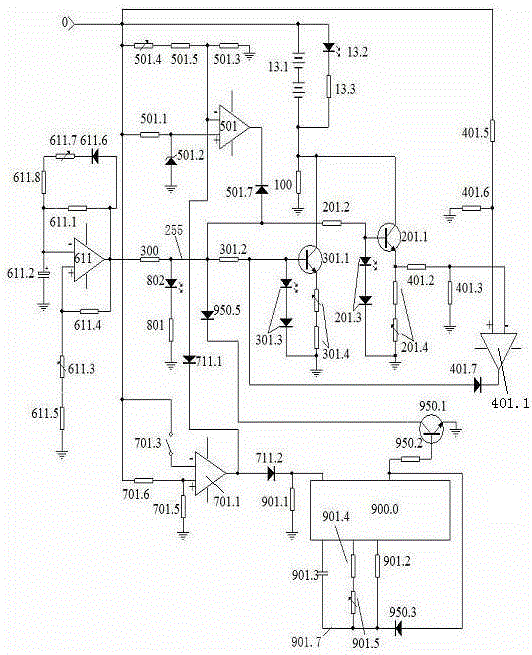

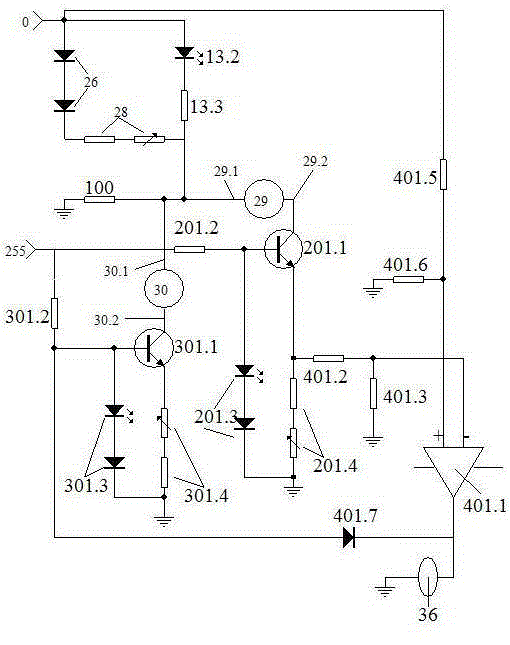

[0100] figure 1 figure 2 image 3 An example of an implementation artifact is given, image 3 Example of detection map in implementation.

[0101] 1. Selection of main components: Computational amplifier, comparison op amp, charging converter, and end switcher are welded with 4 op amps inside an integrated circuit LM324. The transistor in the charging unit is an NPN transistor, the end transistor is 8050, the diode is a surface-bonded diode, the counting oscillation capacitor is a non-polar capacitor, and there is no special requirement for other resistance-capacitance components.

[0102] 2. Make the circuit control board and weld the components: press figure 2 The schematic diagram to make the circuit control board, press figure 2 Schematic of soldered components.

[0103] 3. Power on, check and debug.

[0104] Check that the welding is correct, and then conduct power-on inspection and debugging.

[0105] 1. Check the constant current source part. Check and test se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com