Industrial recirculating-cooling-water-system annual average cooling energy efficiency ratio energy consumption integration evaluation index and method thereof

A circulating cooling water and comprehensive evaluation technology, applied in the comprehensive evaluation index of annual average cooling energy efficiency ratio and energy consumption of industrial circulating cooling water system, industrial energy consumption evaluation index field, can solve improper equipment selection, low system efficiency, high energy consumption, etc. problem, to achieve a reasonable energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Below in conjunction with accompanying drawing and by embodiment the present invention will be further described:

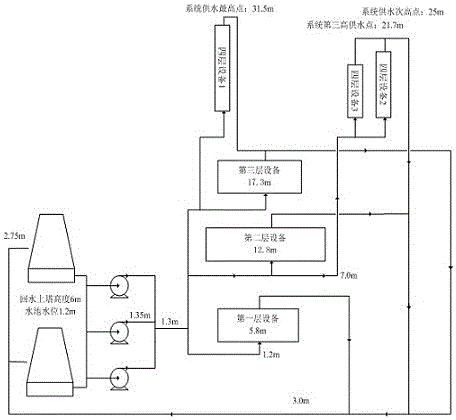

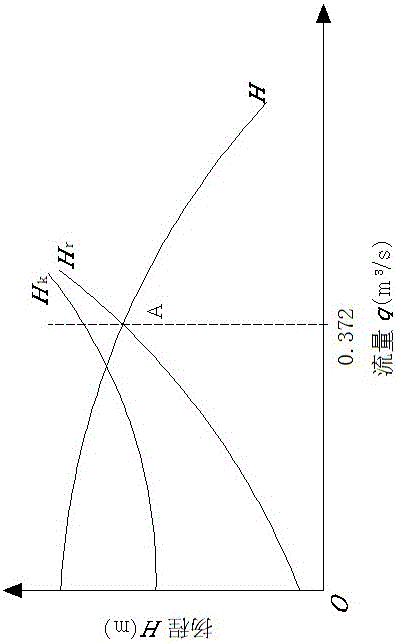

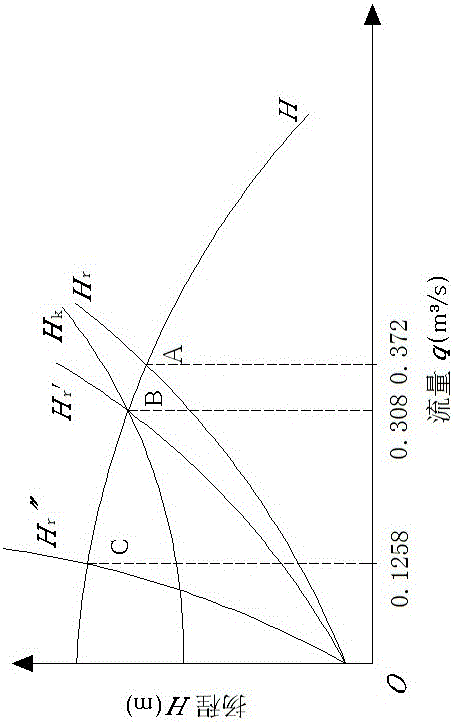

[0062] The circulating cooling water system of a 30,000 tons of aniline and 50,000 tons of nitrobenzene production equipment, such as figure 1 . The system has two GBNF-800 cooling towers, equipped with three parallel circulating water pumps, the model is 350S44A, two are running and one is standby. Single pump flow rate 1116m 3 / h, head 36m, speed 1450r / min. The water pump is equipped with a Siemens Y315L-4 motor with a rated power of 160kW, a rated current of 288A, a motor efficiency of 91.9%, and a rated speed of 1486r / min. The equipment is distributed by layers, and the system is equivalent to five parallel heat exchange user groups, among which the first, second, and third layers of each layer are connected in parallel. There are three devices on the fourth floor, the two devices at the second highest point are connected in parallel, and the devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com