Wire connection device and assembly method thereof

A technology of connectors and junction boxes, which is applied to the assembly/disassembly, connection, conductive connection and other directions of contact parts, which can solve the problems of easy damage, inconvenient installation and use of connectors, and short life, so as to achieve convenient installation and use, and perfect structural sealing , the effect of position stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

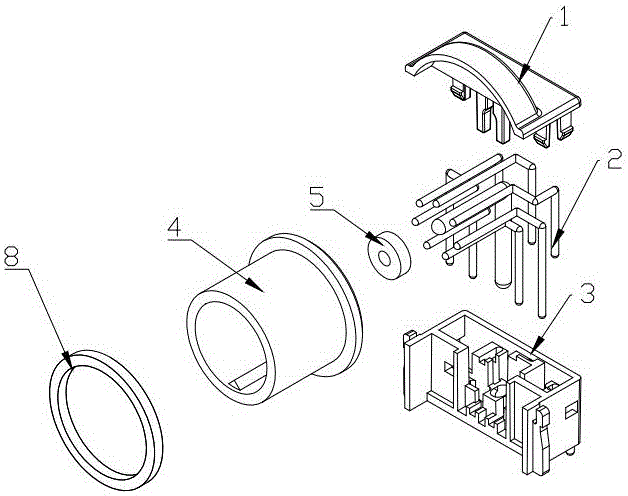

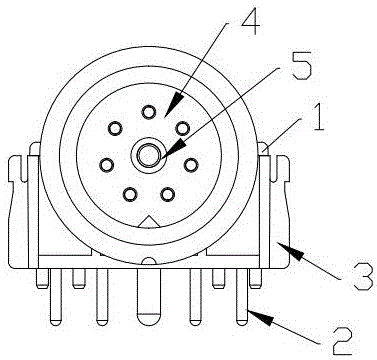

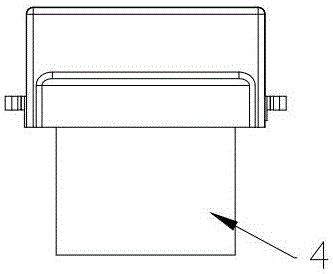

[0036] Embodiment 1: a kind of connector, refer to Figure 1 to Figure 6 , the terminal 2 is installed in the junction box, and there is a space angle of 90° between the outlet end and the inlet end. The terminal 2 includes a certain number of conductive rods, and there is at least one bend on the conductive rods to meet the formation of the space angle. , the junction box includes a sheath 4 at the outlet end and a limit card mold at the outlet end, the limit card mold is provided with a partition unit for isolating each conductive rod and a guide installation hole for positioning each conductive rod.

[0037] The limit card mold includes an upper buckle mold 1 and a lower buckle mold 3, and the upper buckle mold 1 and the lower buckle mold 3 are fixedly connected by an elastic buckle 12, and the elastic buckle 12 is located on the upper buckle mold 1 / lower buckle mold 3, Corresponding lower buckle mold 3 / upper buckle mold 1 are provided with matching buckle windows 31 .

[...

Embodiment 2

[0047] Embodiment 2, the principle is the same as that of Embodiment 1, the difference is that the number of conductive rods is 9, distributed in a circular honeycomb array at the outlet end, and distributed in a square shape at the inlet end, and the square distribution includes three rows and three rows tandem.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com