Method for preparing nano-scale sodalite molecular sieve formed matter

A technology of molding and sodalite, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of reducing the effective specific surface area, reducing the use effect, and unfavorable molecular diffusion in the molecular sieve channels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Mix 7.4 grams of solid silicon dioxide with 7.4 grams of alumina, add 22 milliliters of 26.2% (mass) NaOH aqueous solution, stir until agglomerated, then extrude with a diameter of 2 mm orifice to obtain strips ;

[0029] (2) Dry the strip at 120°C for 2h, and then bake at 650°C for 4h;

[0030] (3) Put the roasted strips into a crystallization kettle, add 94 ml of 26.2% (mass) NaOH aqueous solution, and crystallize at 70° C. for 4 hours;

[0031] (4) The crystallized strips were washed with 0.01M NaOH aqueous solution, then deionized water until neutral, and dried at 70° C. for 3 hours to obtain a nano-sized sodalite molecular sieve shaped product.

[0032] The feeding formula is SiO 2 :Al 2 o 3 : Na 2 O: H 2 O=1:0.5:12.3:52.3.

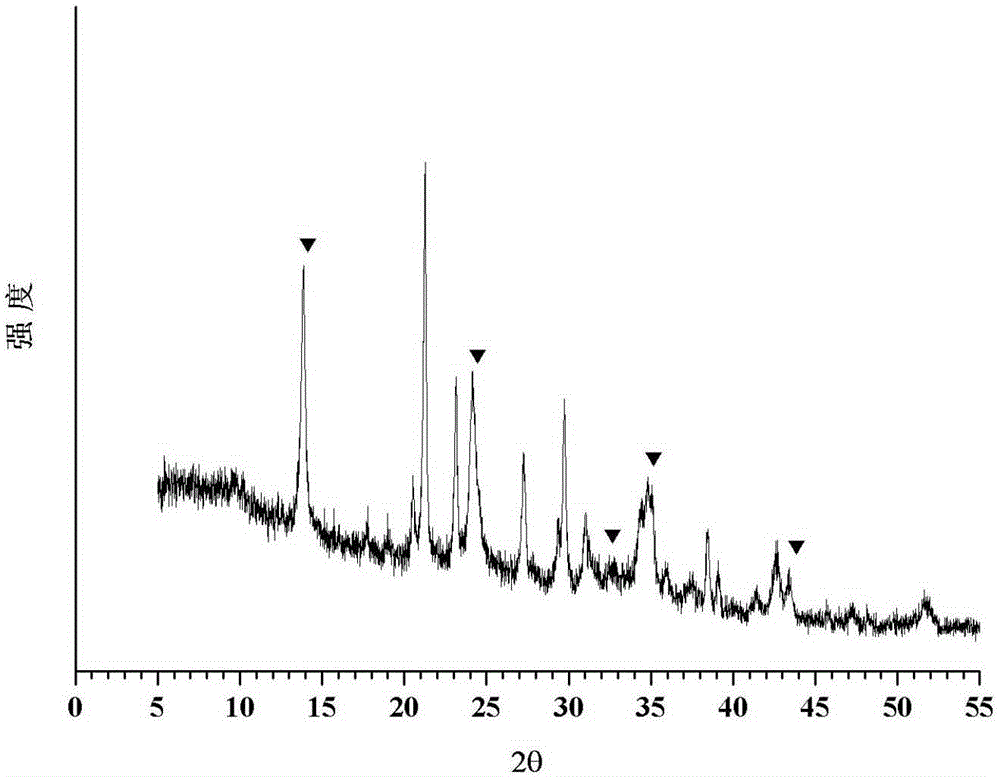

[0033] Characterize the final product, the XRD characterization results are as follows figure 1As shown, the peak marked by the triangle in the figure is the characteristic peak of sodalite, and there are peaks of unreacted alumina...

Embodiment 2

[0035] (1) Stir 7.0 grams of solid silicon dioxide and 7.2 grams of pseudoboehmite evenly, add 26 milliliters of 18.0% (mass) NaOH aqueous solution, stir until agglomerated, and then use an orifice plate with a diameter of 8 mm to extrude get strips;

[0036] (2) Dry the strips at 70°C for 8h, and then roast at 680°C for 4h;

[0037] (3) Put the roasted strips into a crystallization kettle, add 94 ml of 20.5% (mass) NaOH aqueous solution, and crystallize at 80° C. for 4 hours;

[0038] (4) Wash the crystallized strips with 0.01M NaOH aqueous solution, and then wash with deionized water until neutral. Dry at 70° C. for 3 hours to obtain a nano-sized sodalite molecular sieve shaped product.

[0039] The feeding formula is SiO 2 :Al 2 o 3 : Na 2 O: H 2 O=1:0.4:10.4:66.7.

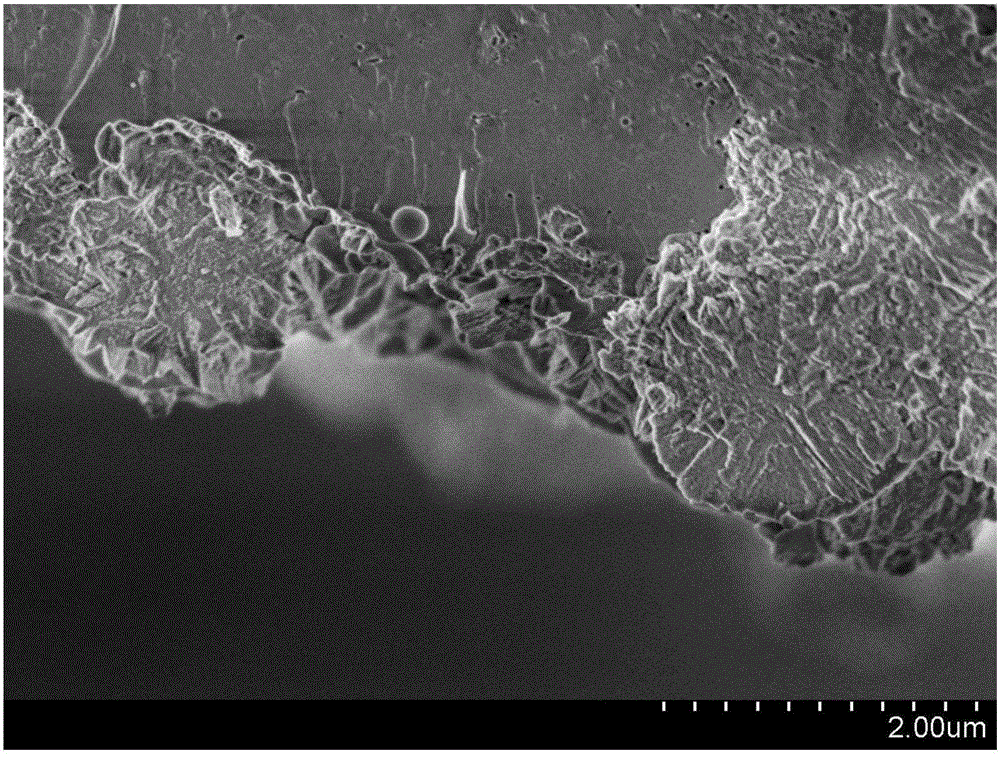

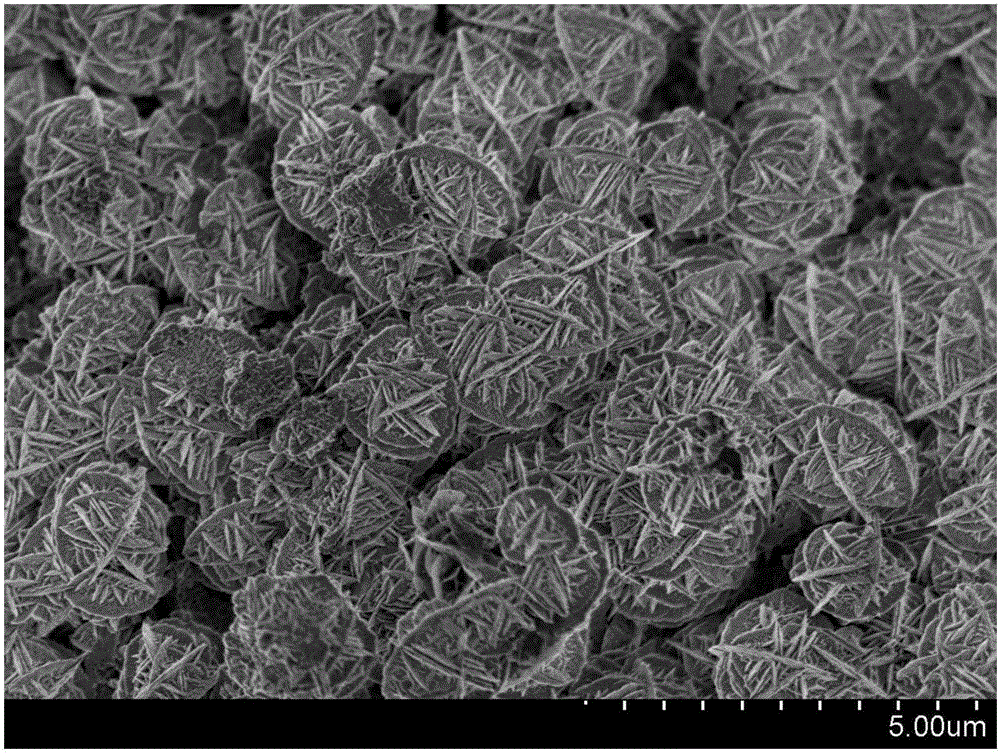

[0040] The XRD characterization results are the same as figure 1 . The SEM characterization results of the center of the bar cross section are as follows Figure 4 As shown in , it can be seen that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com