Hyperbranched diazonium salt-based polyurethane hydrophilic modification method

A hydrophilic modification and polyurethane technology, which is applied in the field of sewage treatment, can solve the problems of low microbial adhesion, cumbersome steps, and slow film formation, and achieve the effects of easy operation, high reactivity, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

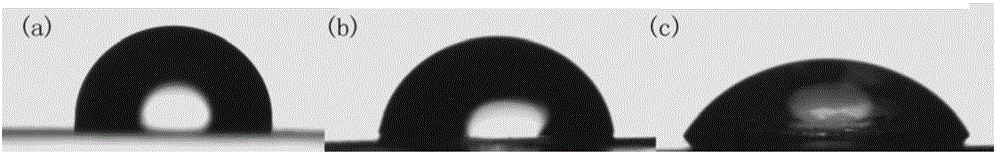

[0038] The method for the hydrophilic modification of polyurethane based on hyperbranched diazonium salt of the present invention, comprises the steps:

[0039] (1) Dilution of hyperbranched diazonium salt solution: Measure a certain volume of hyperbranched diazonium salt solution, dilute it to 50 times with water, and then store it at 8°C to ensure the stability of hyperbranched diazonium salt ;

[0040] (2) Grafting of the carrier: at a temperature of 2° C., the polyurethane carrier is immersed in the diluted hyperbranched diazonium salt solution for 0.5 h, wherein the polyurethane carrier is a cube with a side length of 10 mm;

[0041] (3) Hydrophilic modification of polyurethane: take out the polyurethane carrier, clean it with water, and dry it quickly with cold wind at 7°C; at a temperature of 2°C, immerse the polyurethane carrier in polystyrene sulfonic acid Sodium solution for 2 hours to achieve saturated adsorption, take it out and blow dry, that is to complete the p...

Embodiment 2

[0044] The method for the hydrophilic modification of polyurethane based on hyperbranched diazonium salt of the present invention, comprises the steps:

[0045] (1) Dilution of hyperbranched diazonium salt solution: Measure a certain volume of hyperbranched diazonium salt solution, dilute it to 100 times with water, and then store it at 2°C to ensure the stability of hyperbranched diazonium salt ;

[0046] (2) Grafting of the carrier: at a temperature of 6° C., the polyurethane carrier was immersed in the diluted hyperbranched diazonium salt solution for 2 hours, wherein the polyurethane carrier was a cube with a side length of 20 mm;

[0047] (3) Hydrophilic modification of polyurethane: take out the polyurethane carrier, clean it with water, and dry it quickly with cold wind at 1°C; at a temperature of 6°C, immerse the polyurethane carrier in polymethacrylic acid Put it in the solution for 8 hours to achieve saturated adsorption, take it out and blow dry, and complete the p...

Embodiment 3

[0050] The method for the hydrophilic modification of polyurethane based on hyperbranched diazonium salt of the present invention, comprises the steps:

[0051] (1) Dilution of hyperbranched diazonium salt solution: Measure a certain volume of hyperbranched diazonium salt solution, dilute it to 70 times with water, and then store it at 4°C to ensure the stability of hyperbranched diazonium salt ;

[0052] (2) Grafting of the carrier: at a temperature of 4° C., the polyurethane carrier was immersed in the diluted hyperbranched diazonium salt solution for 1 hour, wherein the polyurethane carrier was a cube with a side length of 14 mm;

[0053] (3) Hydrophilic modification of polyurethane: take out the polyurethane carrier, clean it with water, and dry it quickly with cold wind at 3°C; then immerse the polyurethane carrier in the polyacrylic acid solution at a temperature of 4°C 6h, in order to achieve saturated adsorption, take it out and blow dry, that is to complete the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com