Dry salt pickling device

A dry salt and rack technology, applied in the field of dry salt pickling machine, can solve the problems of manpower and time consumption, low degree of mechanization, accelerated fat oxidation, etc., to achieve convenient installation and inflation, shorten pickling time, increase compactness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

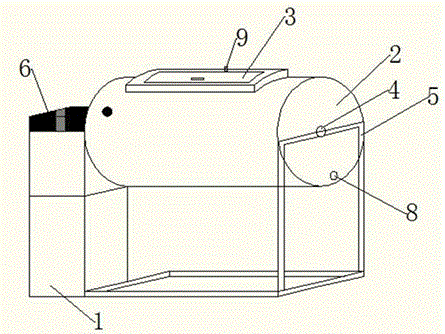

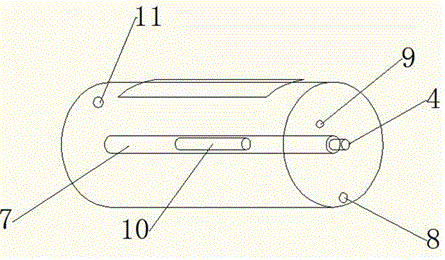

[0019] It can be seen from the drawings that a dry salt curing machine includes a frame 1, a curing box 2, and a sealed box cover 3 is provided on the curing box 2; a geared motor 6 and Rotating seat 5, said pickling box 2 is provided with a rotating shaft 4, said rotating shaft 4 is mounted on the rotating seat 5, and the output end of said reduction motor 2 is connected to the rotating shaft 4 through a coupling. The method comprises: an expansion air cylinder 7 is arranged at the center of the salting box 2, and a water discharge switch 8 and an air inlet switch 9 for connecting the air pump intake pipe to the air cylinder are arranged on the outer surface of the salting box 2; A vibrator 10 is also provided in the box.

[0020] Because the marinating box can be rotated 360 degrees by the rotation of the motor, the rotation of the marinating box can be adjusted by adjusting the rotation speed of the reducer, and the marinating box can be rotated at a low speed to make the food...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com