A pickling rack of a dry salt pickling machine

A dry salt and airtight box technology, applied to the curing rack of dry salt curing machine and the field of dry salt curing machine, can solve the problems of low degree of mechanization, uneven penetration of salt, accelerated fat oxidation, etc., so as to shorten the curing time. The effect of curing time and marinating is sufficient and uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

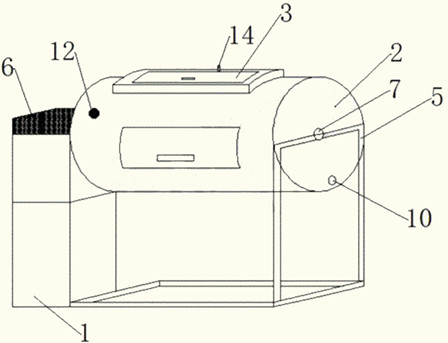

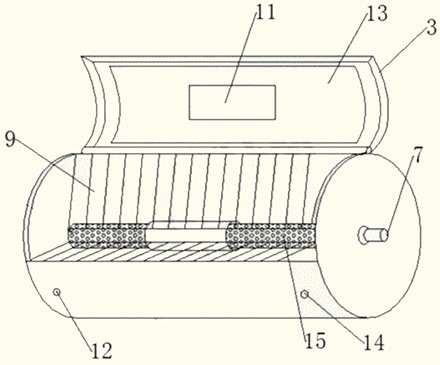

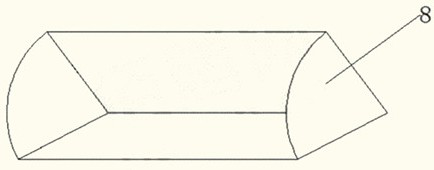

[0020] As can be seen from the accompanying drawings, the present invention provides a marinating frame 2 of a dry salt curing machine, the central position of the marinating frame 2 is provided with a rotating shaft 7, and the interior of the marinating frame 2 is provided with The pickling frame 9 that pickling grid 8 cooperates with each other; described pickling frame 2 is divided into pickling frame 9 by interlayer baffle plate 15, and described interlayer baffle plate 15 is divided into pickling frame 9 through the central position of pickling frame 2. Frame 9, the pickling grid 8 is a split box structure that cooperates with the pickling frame 9, and the pickling frame 2 is provided with a sealed box cover 3 at the outlet of the pickling frame 9; The sealing box cover 3 is provided with an extruding device; the sealing box cover 3 is provided with an extruding device as an inflatable expansion device, and the described sealing box cover 3 is provided with an intake switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com