Production method of nanoscale rice starch

A technology of rice starch and production method, applied in the production field, can solve the problems of long preparation time and high production cost, and achieve the effects of convenient vibration and fast positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

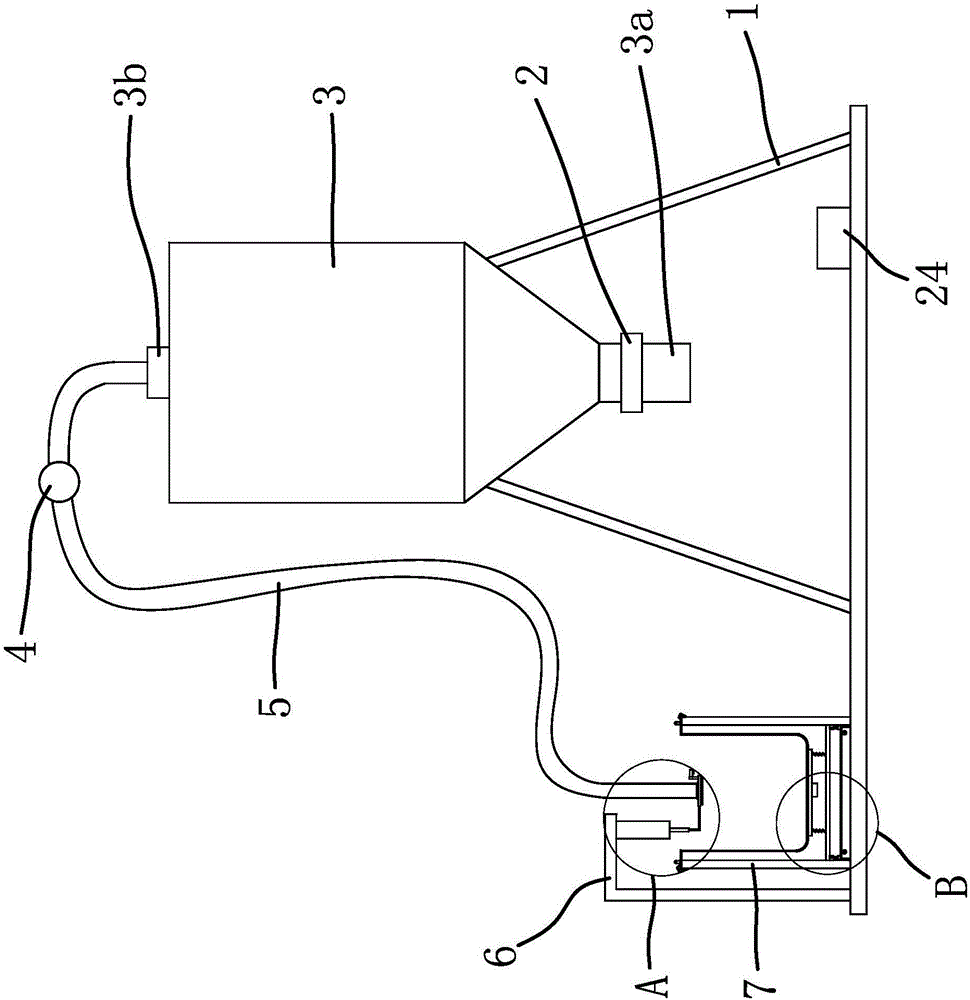

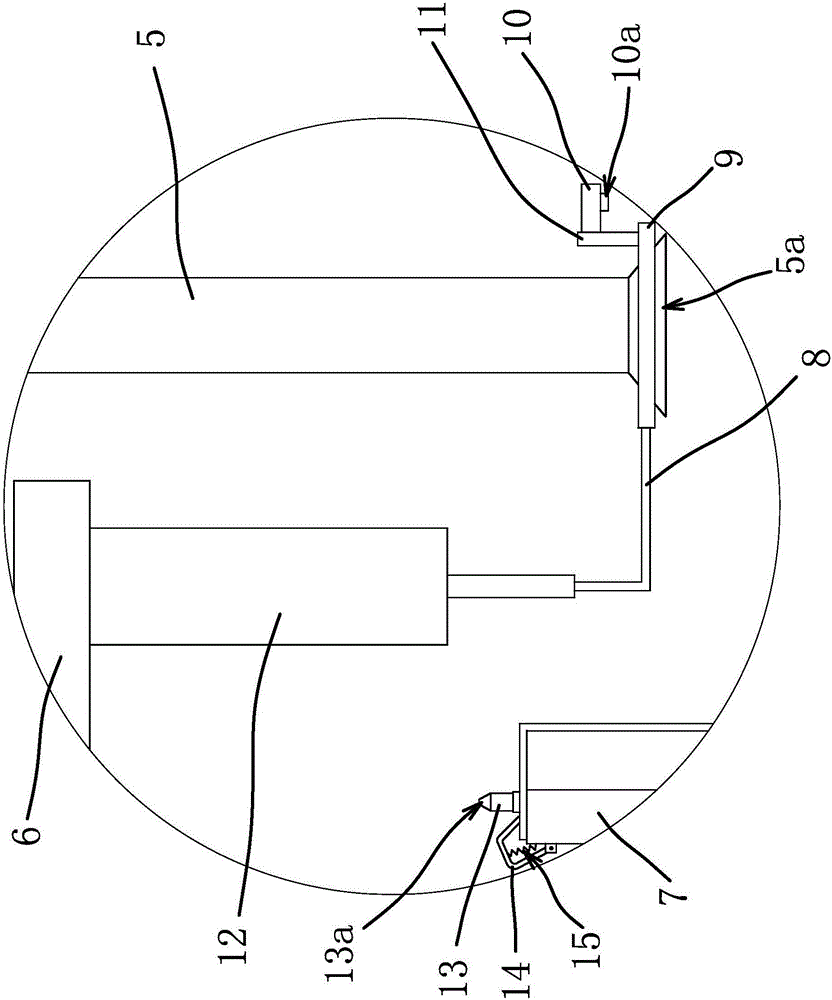

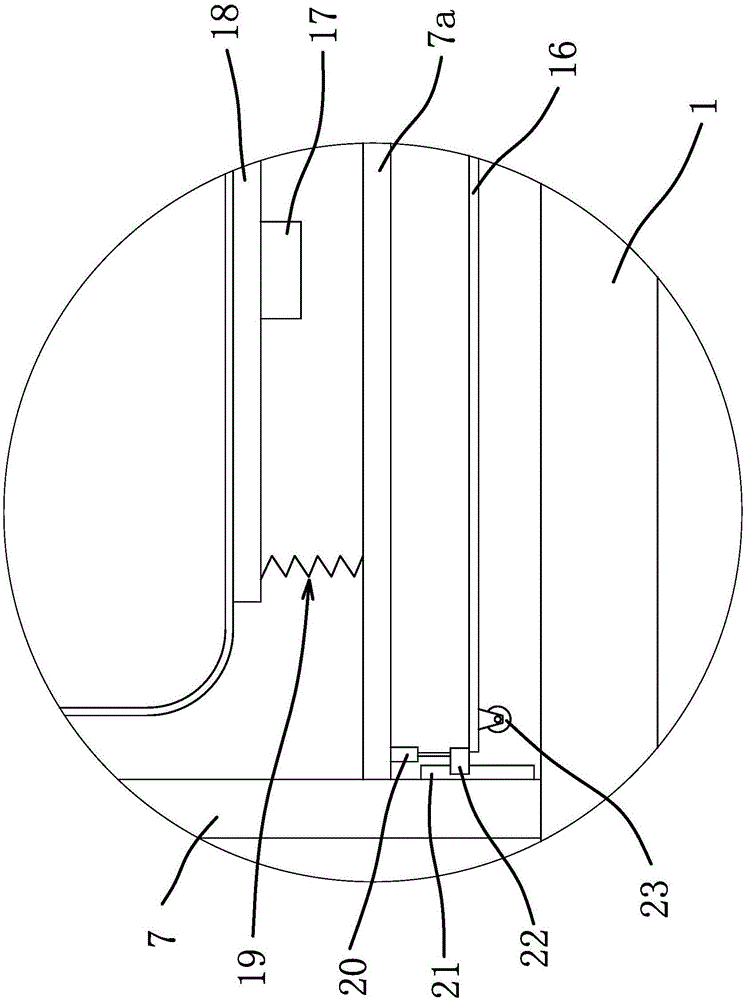

[0067] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0068] The production method of this nanoscale rice starch, the raw material of production is rice, comprises the steps:

[0069] a. Preparation of rice starch: first soak the rice in 0.8% sodium hydroxide aqueous solution for 16-20 hours, stir it every 4 hours, pour out the soaking liquid, pass through a colloid mill after beating with a beater, and then soak with 0.8% sodium hydroxide aqueous solution After 12-16 hours, pour out the soaking solution, add deionized water, centrifuge, pour off the supernatant, and repeat washing 3-5 times; after adding deionized water for the last time, adjust the pH value to neutral, centrifuge, and the resulting precipitate It is rice starch; in this embodiment, first soak the rice in 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com