Specific-gravity stoner

A destoner, specific gravity technology, applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problems of low cost performance, affecting the quality of rice, complex structure and strong vibration, etc. Reduce vibration, improve stone removal efficiency, and better stone removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

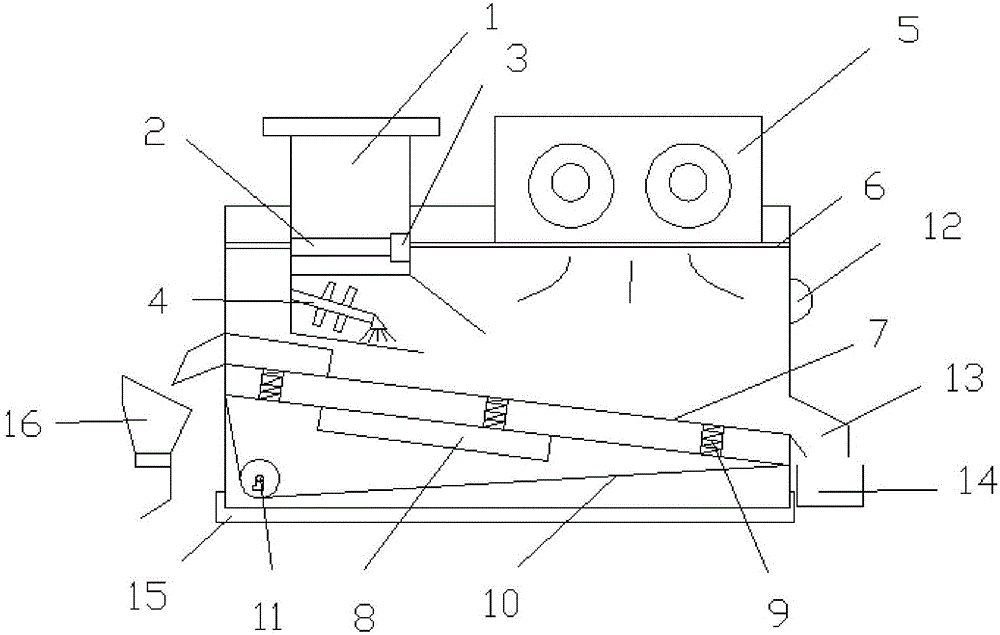

[0018] Such as figure 1 Shown, a kind of specific gravity destoner machine comprises exhaust fan 5 and destoner device, and described exhaust fan 5 air outlets stretch into destoner device, and destoner device comprises feeding port 1, vibrating screen cloth 7, vibrating motor 8, The feeding port 13 and the stone bucket 16, the feeding port 1 is erected on the upper end of the vibrating screen 7, the bottom of the vibrating screen 7 is connected to the vibrating motor 8 and placed obliquely at an obtuse angle with the horizontal plane, the feeding port 13, The stone receiving bucket 16 is arranged on the lower end surface and the upper end surface of the vibrating screen 7 respectively, a filter screen 6 is provided on the horizontal plane where the air outlet of the exhaust fan 5 intersects with the stone removal device, and a cushioning pad 15 is provided at the bottom of the stone removal device .

[0019] The lower end of the feeding port 1 is horizontally equipped with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com