Food waste four-stage sorting and impurity removal system

A technology of food waste and sorting system, which is applied in classification, solid separation, solid waste removal, etc., can solve the problem of slow falling speed of moving solid waste, so as to speed up the efficiency of rough sorting and the speed of cracking and dispersing , good fermentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

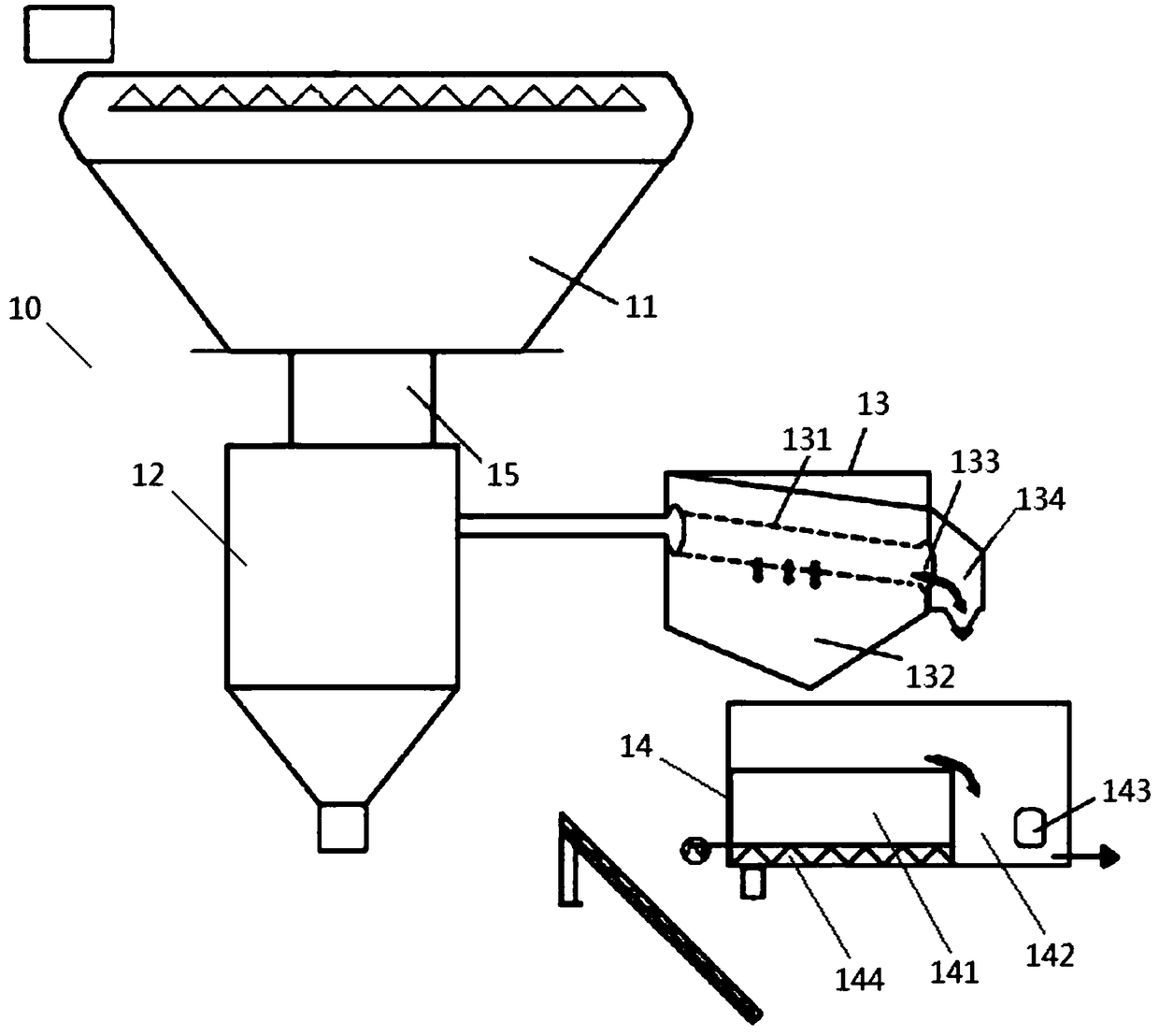

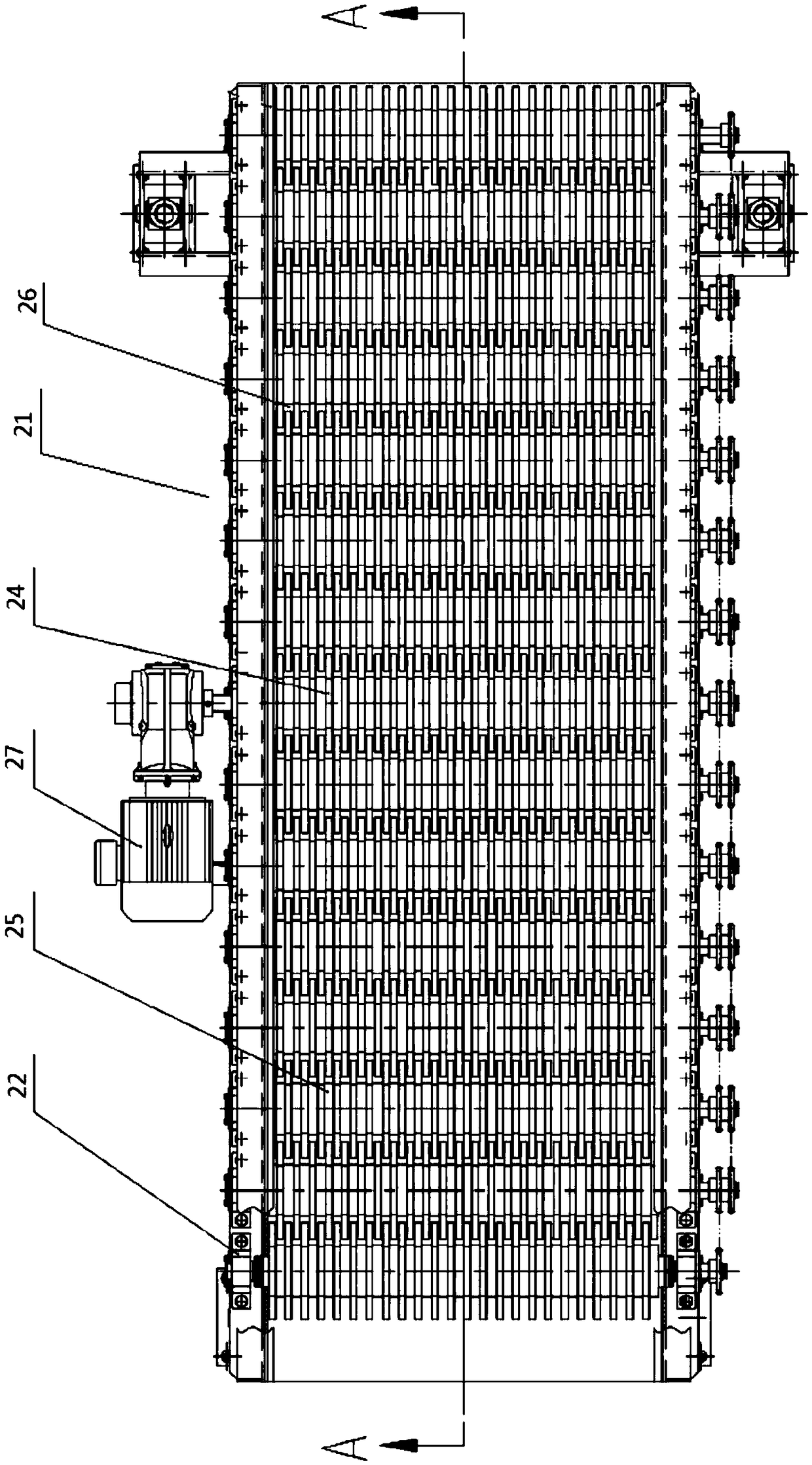

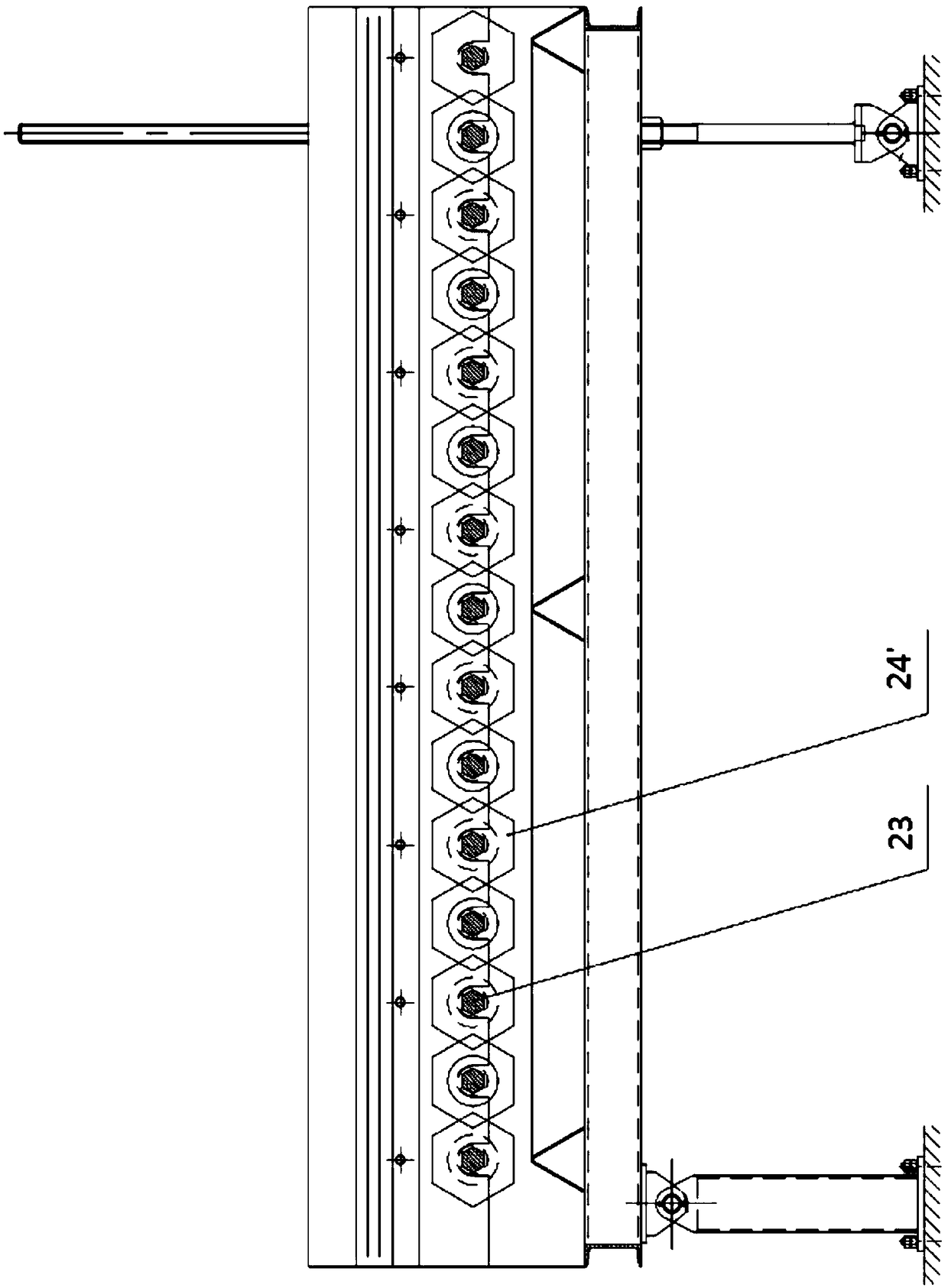

[0034] see Figure 4 , The invention provides a four-stage sorting and impurity removal system for food waste. The system includes a coarse material sorting system 100, a crushing and humidity-adjusting pulping system 200, a light foreign matter sorting system 300, and a fine sand sorting system 400, and the above four systems are arranged in sequence along the flow direction of food waste sorting . exist Figure 4 In , two four-stage sorting system production lines are given, and the direction of the arrow is from left to right, which is the sorting flow direction of food waste. After the food waste is put into the receiving system, it is sent to the coarse material sorting system 100, the crushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com