A method for controlling the shape of oriented silicon steel wedge plate

A shape control, oriented silicon steel technology, applied in contour control, manufacturing tools, metal rolling, etc., can solve problems such as center offset, and achieve the effect of improving shape, eliminating strip edge waves, and uniform transverse dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

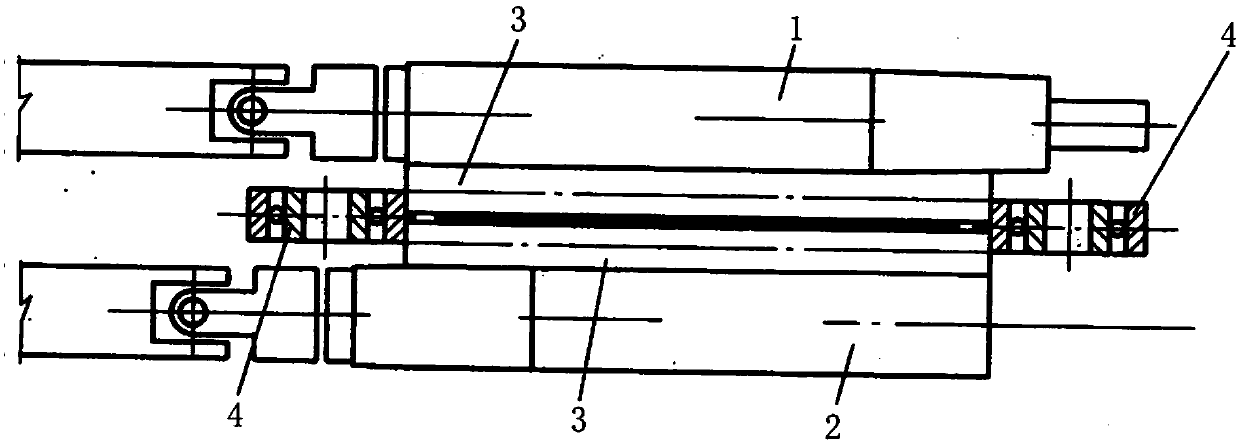

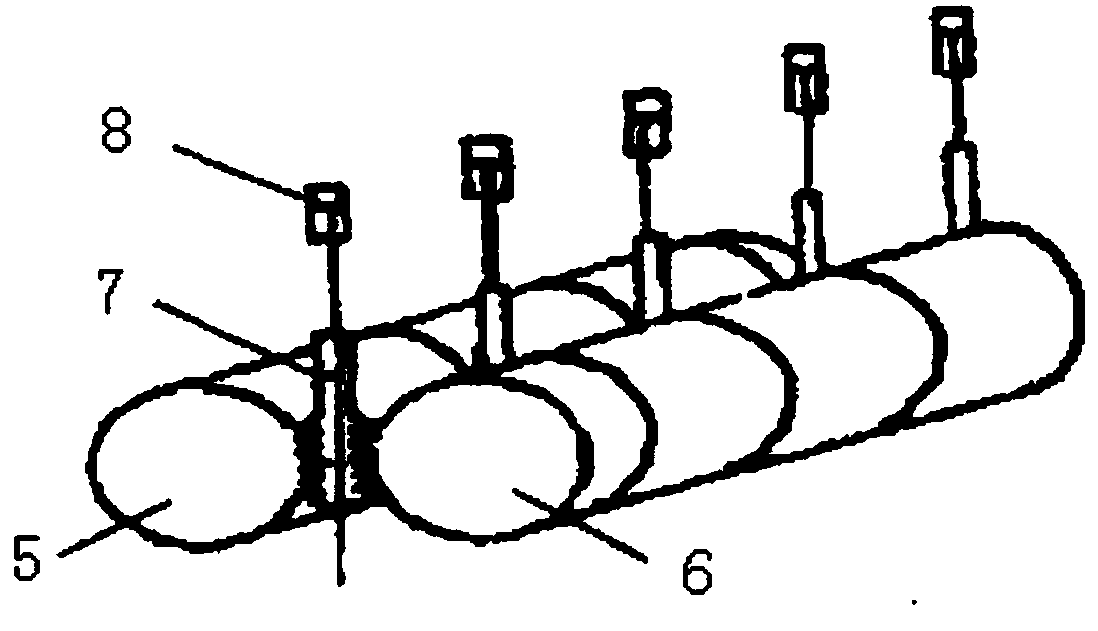

Method used

Image

Examples

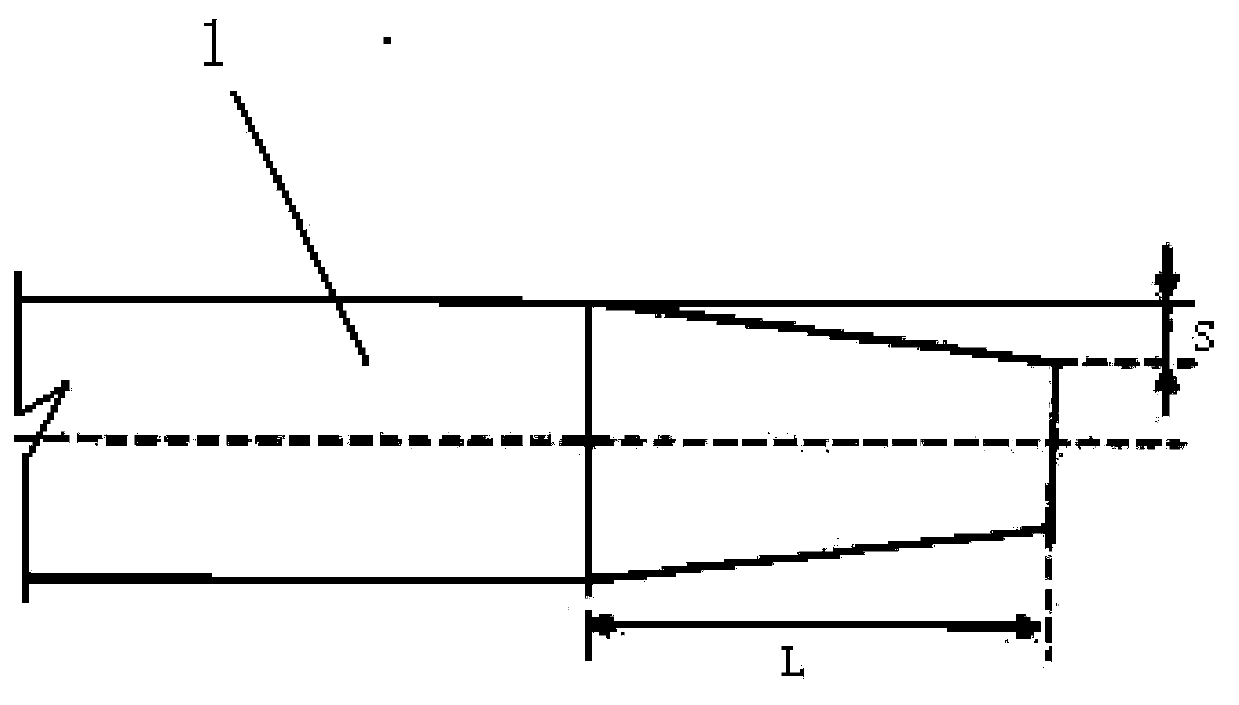

Embodiment 1

[0028] The thickness of the oriented silicon steel billet is 2.3mm and the width is 1300mm. The billet is cut from the middle, and the thicker strip on the working side of the rolling mill (that is, the side close to the main operator) is defined as volume A, and the thin strip on the working side is defined as volume B. Five positions are randomly selected to measure the thickness of the strip on the working side of the strip and the edge of the transmission side. The data are shown in Table 1:

[0029] Table 1:

[0030]

[0031] The measurement data shows that the thickness difference of the wedge-shaped plate after the billet is cut is in the range of 0.04-0.07mm, which meets the supply standard of hot-rolled billet.

[0032] Based on the length of the guide roll at the rolling exit of 850mm, the width of the billet is 650mm, and the experiment is carried out according to the standard rolling process. The distance between the edge of the strip and the edge of the guide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com