Cold upsetting forming method for power supply pin

A molding method and pin technology, applied in steering mechanism, connecting rod, mechanical equipment and other directions, can solve the problems of high material cost, low production efficiency and high processing cost, achieve high material utilization rate, improve production efficiency and reduce material cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0028] The cold heading forming method of the power pin of the present invention comprises the following steps:

[0029] Step 1, intercept the blank ( figure 1 ), is to apply the intermittent stepping automatic material cutting system, which automatically cuts out a reasonable length of the blank 1 from the coiled wire material whose diameter is close to the circumscribed circle of the power pin body or the coiled wire material with a reasonable strength beam ratio, and automatically The feeding system is synchronously transported to the cold extrusion station of the multi-stroke cold heading machine; the shape of the blank 1 can be a cylinder, which is automatically intercepted by the coil wire for cold heading.

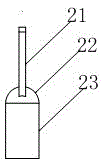

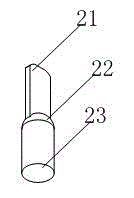

[0030] Step 2, the diameter of the power pin body is reduced and preform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com