Drilling clamp for shell cover part of hay mower and use method thereof

A technology for parts and drill sleeves is applied in the field of drilling fixtures for lawn mower casing cover parts, which can solve the problems of easy deformation, difficult control of machining accuracy, and difficult machining, and achieves low cost, improved drilling efficiency, and improved handling and disassembly. Maintenance-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

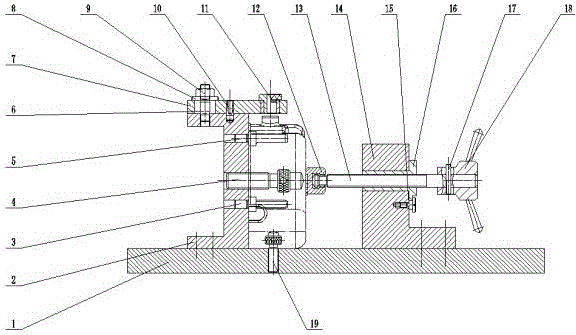

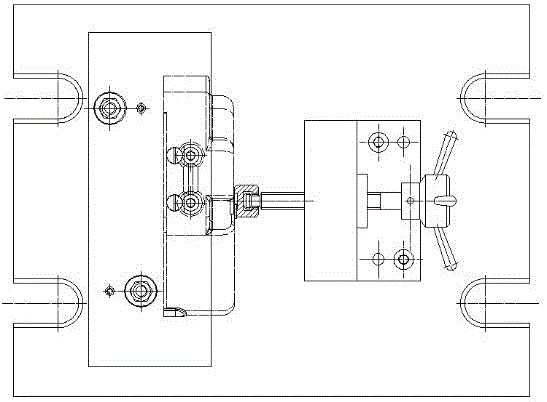

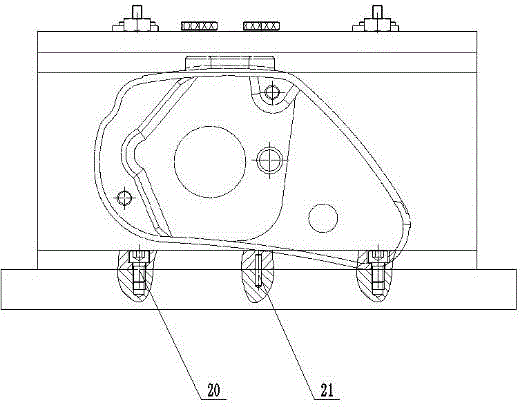

[0040] Embodiment 1: as Figure 1~Figure 3 As shown, a drilling jig for mower housing cover parts includes a bottom plate, a left baffle 2 and a cylindrical head adjustment support 19 are arranged on the bottom plate 1, and the left baffle is passed through 2 cylindrical pins 21 and hexagon socket head screws. 20 is connected and fixed, and a B-shaped fixed positioning pin 3 and an A-shaped fixed positioning pin 5 are installed on the left baffle 2 to realize the positioning of the parts with the side of the left baffle 2, which limits 6 degrees of freedom; on the bottom plate 1 The right side of the right side connects right baffle plate 14, and pressing device is installed above the right baffle plate 14, realizes that the position of parts remains unchanged during processing.

[0041] The above-mentioned B-type fixed positioning pin 3 and A-type fixed positioning pin 5 are fixedly connected on the left baffle plate 2 through cooperation, which is convenient and quick to ins...

Embodiment 2

[0045] Embodiment 2: When drilling, put the part on the clamp body, quickly locate it through the B-type fixed positioning pin 3 and the A-type fixed positioning pin 5, and use the smooth pressing block 12 of the screw fastening device to tighten it. Fix, quickly realize the installation of the fixture, and then put the fixture with the installed parts on the workbench of the radial drilling machine to realize the drilling process.

[0046] A method for using a drilling jig for a part of a lawnmower housing cover, comprising the following steps:

[0047] (1) Install the left panel on the base;

[0048] (2) Install the positioning pin and cylindrical head adjustment support to the left side plate;

[0049] (3) Install the screw clamping device on the right side plate and fix it with the bottom plate;

[0050] (4) Install the drill template on the left side plate and fix the drill sleeve;

[0051] (5) Place the part on the corresponding position on the clamp body for position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com