Guide blade edge plate dustpan hole machining rapid changing clamping device and method

A technology of guide vane and clamping device, which is applied in the direction of accessory devices, electric processing equipment, metal processing equipment, etc., can solve the problems of complex clamping structure, inconvenient operation, and many angles involved in the dustpan hole, so as to achieve convenient operation and improve replacement. Model efficiency, compact structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

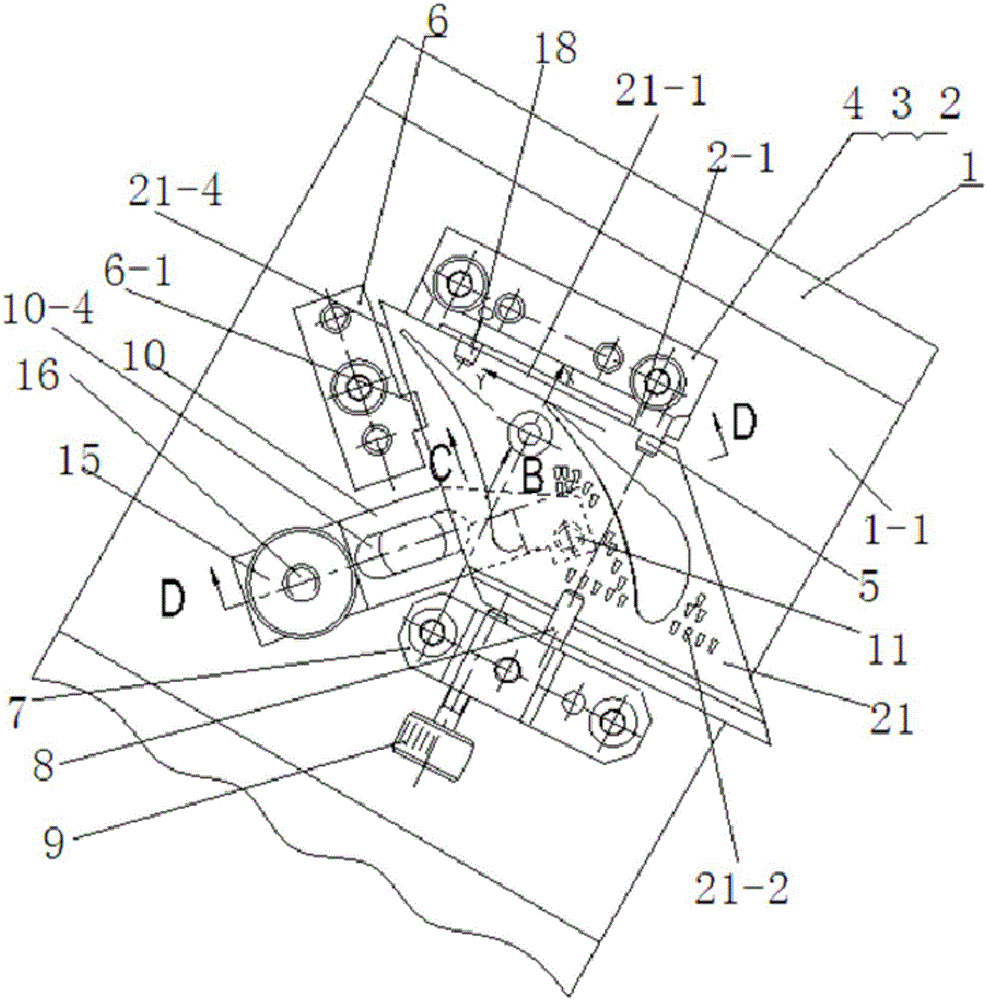

[0046] The present invention will be further described below in conjunction with the accompanying drawings.

[0047] The purpose of the present invention is to design a fast-changing clamping device for machining the dustpan hole of the edge plate of the guide vane, so as to reduce the labor intensity and improve the processing efficiency.

[0048] The purpose of this method is to realize by following steps:

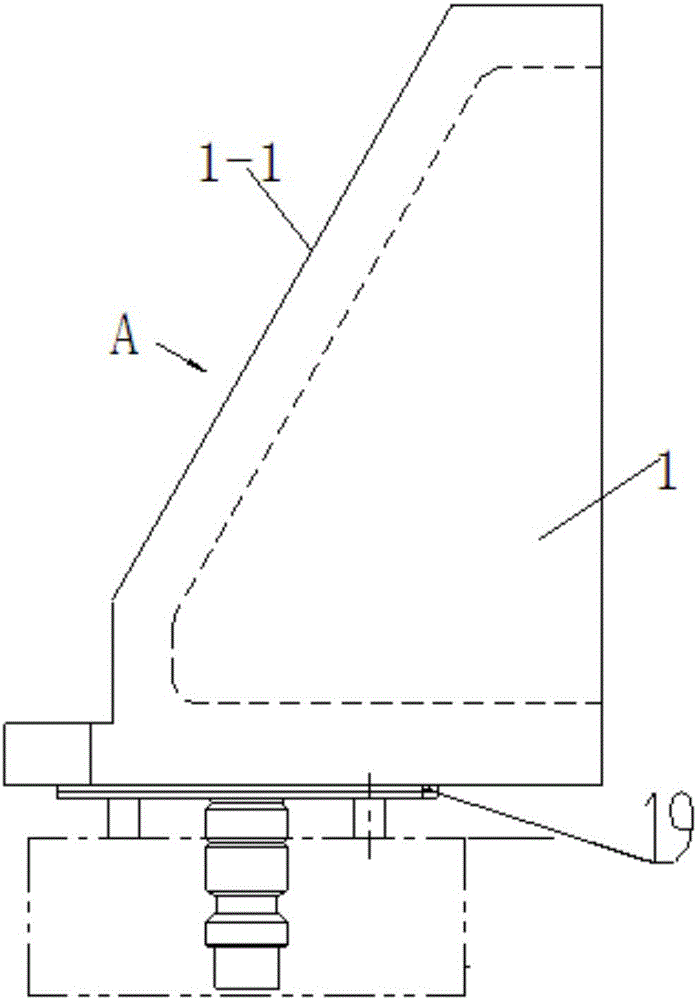

[0049] 1) Design an integral clamping structure, and directly design the upper positioning point on the body 1 to save space.

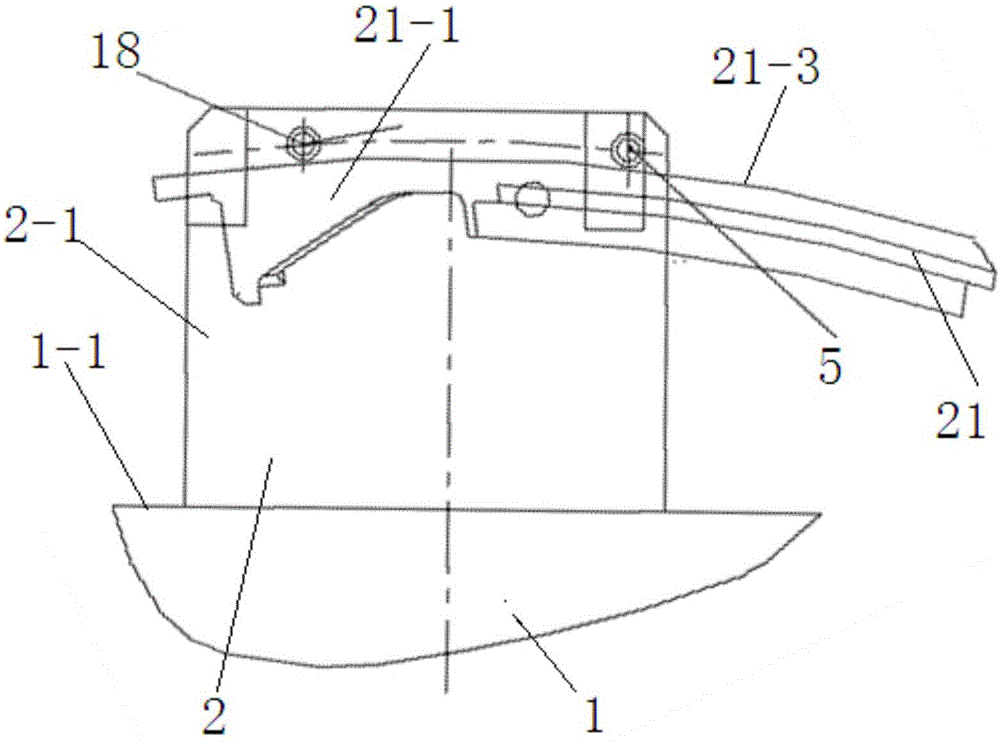

[0050] 2) In tooling design, the technology based on 3D solid design is used to reversely design the fixture body directly from the UG shape of the guide vane edge plate 21, and directly perform structural weight reduction optimization on the solid model of the fixture to make the volume small enough.

[0051] 3) Except for the clamping and positioning components, the other components including the clamping device body 1 are all made of cast al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com