Firm robot welding control cabinet

A robot welding and control cabinet technology, which is applied in the field of robots, can solve the problems of supporting plates and vertical plates falling off, unreliable supporting tables, and low cooling efficiency, so as to reduce the failure rate, improve cooling efficiency, and achieve high cooling efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

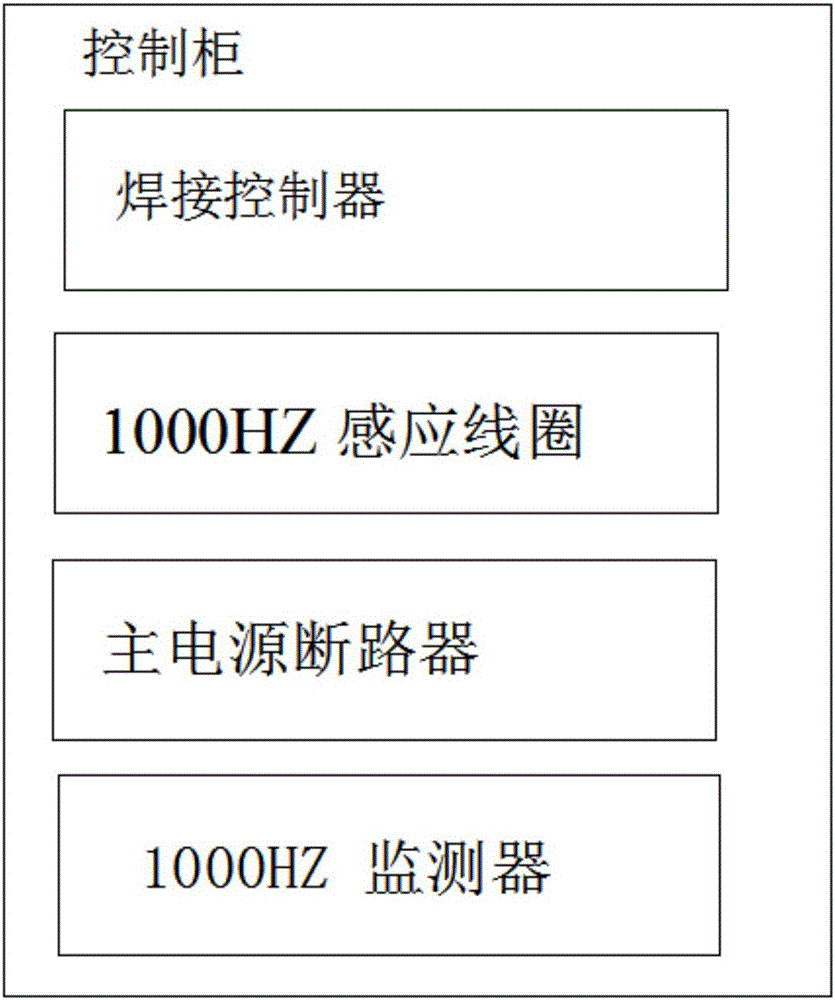

[0022] According to attached Figure 1-Figure 5 It can be seen that a reliable robot welding control cabinet of the present invention includes a cabinet body provided with a welding controller, a 1000HZ induction coil, a main power circuit breaker and a 1000HZ monitor;

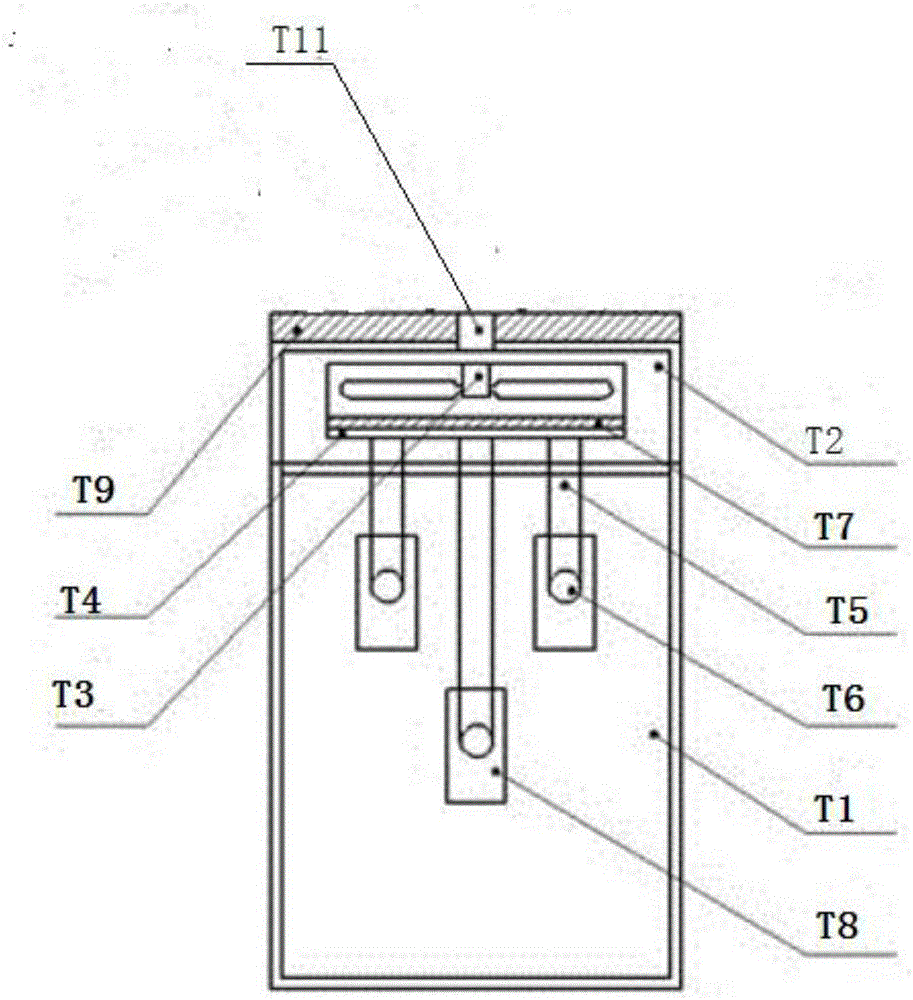

[0023] Inside the cabinet T1 is set up an accommodation chamber T2 for accommodating the air intake machine T3; the air intake machine T3 is erected in the accommodation room T3, and the lower end of the accommodation room T2 has a through-type air supply hole T4, and the air supply hole T4 communicates with the air guide channel T5, and a second sieve plate T7 is arranged on the inner wall of the air delivery hole T4, and the tail of the air guide channel T5 is the air delivery end T6, and the air delivery end T6 is arranged on On the rear wall of the cabinet T1, the air supply terminal T6 is connect...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap