Cutting device

A cutting device and tape cutting technology, which is applied to fine working devices, stone processing tools, working accessories, etc., can solve the problems of troublesome adjustment, imperfect segmentation, damage to the surface of the substrate, etc., and achieve reliable and effective segmentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

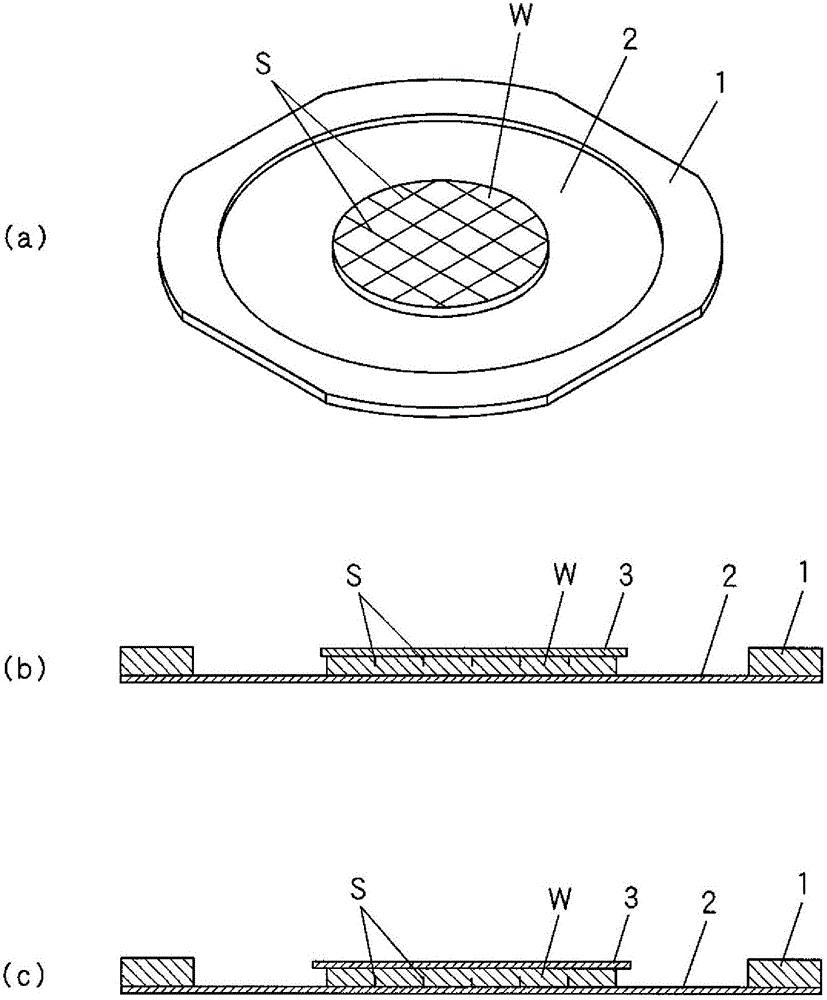

[0030] Hereinafter, the present invention will be described in detail based on the embodiments shown in the drawings. In this embodiment, the semiconductor substrate W to be processed is mainly a semiconductor substrate for an image sensor, and its form is the same as that described above. figure 1 The semiconductor substrates shown are the same. Below, yes figure 1 Cutting of the semiconductor substrate W in (c) will be described.

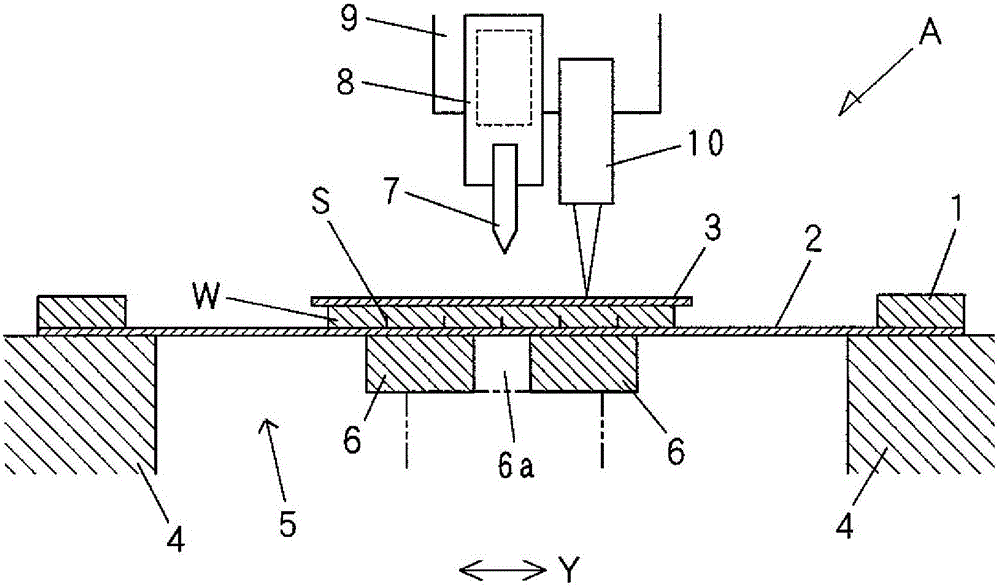

[0031] figure 2 It is an explanatory diagram showing a cutting mechanism portion of the cutting device A of the present invention, and includes a table 4 on which a semiconductor substrate W is placed together with a dicing frame 1 . A space 5 is provided in the middle of the table 4, and a pair of left and right passive knives 6, 6 are arranged in the space 5. As shown in FIG. The gap 6a formed between the passive blades 6, 6 is figure 2 Extending in the front-back direction (X direction) of the space 6a, a long plate-shaped cutting strip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com