Internal mixing chamber dismounting and mounting device of internal mixer

The technology of a mixing chamber and an internal mixer is applied in the field of disassembling and assembling devices of a mixing chamber of an internal mixer, which can solve the problems of low work efficiency, high operation difficulty, high labor intensity of workers, etc., and achieves high work efficiency and production safety. Good, the effect of low labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

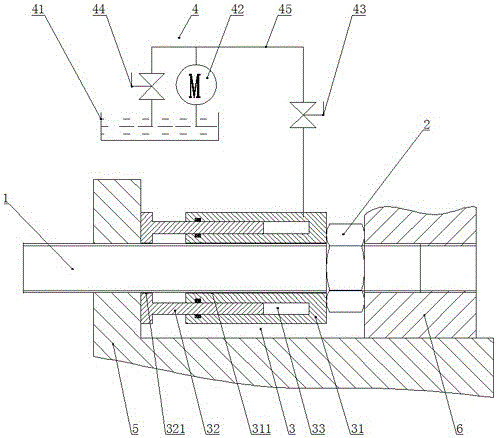

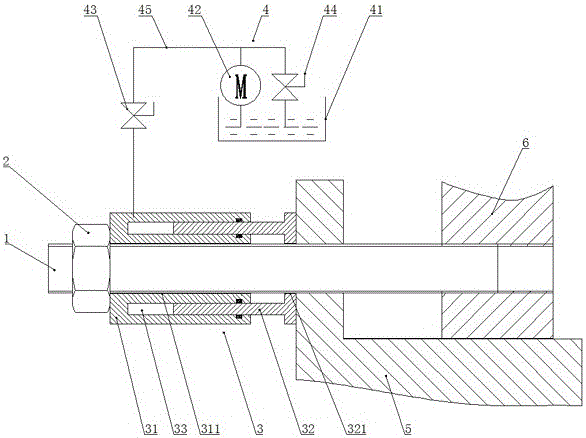

[0011] Such as figure 1 , figure 2 As shown, a disassembly device for a mixing chamber of an internal mixer, which includes a lead screw 1, a positioning nut 2 threaded on the lead screw 1, a hydraulic cylinder 3 and a hydraulic control system 4.

[0012] exist figure 1 , figure 2 Among them, the hydraulic cylinder 3 includes a cylinder body 31 and a piston 32 . Wherein, a first through hole 311 is opened on the cylinder body 31 of the hydraulic cylinder 3, and an annular oil chamber 33 is formed in the cylinder body 31, and the piston 32 of the hydraulic cylinder 3 matches the annular oil chamber 33; A second through hole 321 is opened on the piston 32 coaxially with the first through hole 311 , and the cylinder body 31 and the piston 32 of the hydraulic cylinder 3 are fitted on the lead screw 1 through the first through hole 311 and the second through hole 321 respectively. Such as figure 1 , figure 2 As shown, the piston 32 of the hydraulic cylinder 3 abuts against...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com