Automatic width adjusting device for mold head of plastic composition machine

A compound machine and die head technology, which is applied in the field of automatic amplitude adjustment devices for plastic compound machine die heads, can solve problems affecting normal production, damage to feeler gauges and die heads, and difficulty in amplitude adjustment, so as to improve production efficiency and enterprise economic benefits, Improve uniformity and compactness, easy and reliable effect of amplitude modulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiment is further described in detail below in conjunction with accompanying drawing:

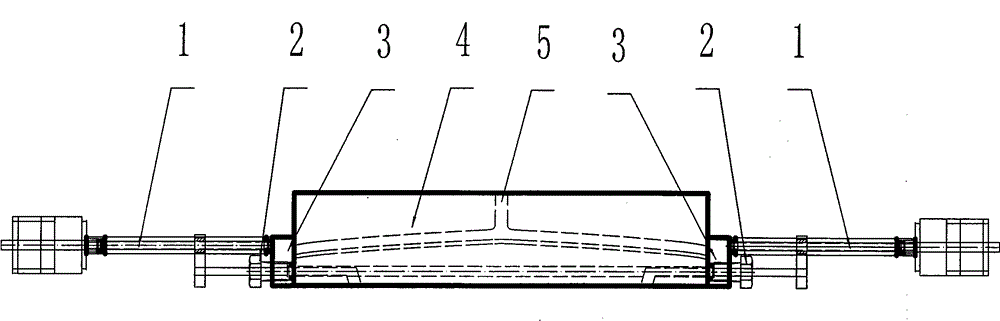

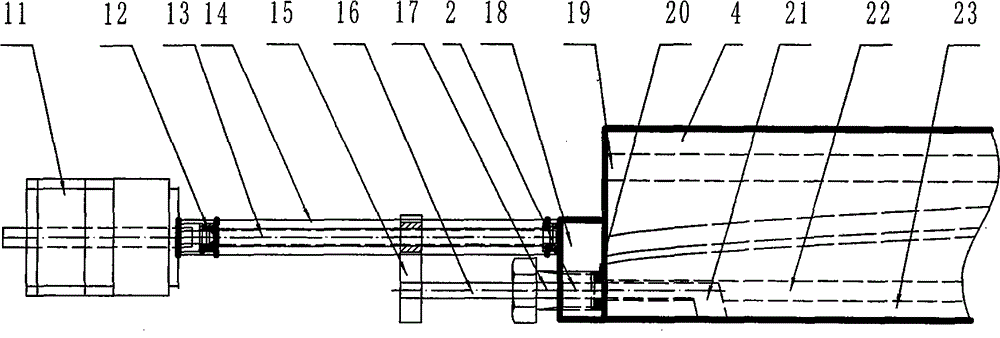

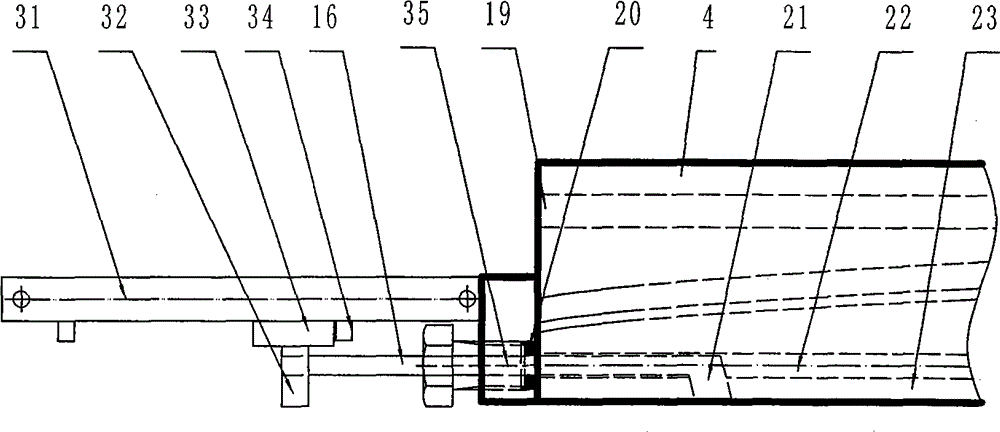

[0016] refer to figure 1 , figure 2 : figure 1 It is a side view structural schematic diagram of an embodiment of the device of the present invention, figure 2 It is a partial side view structure schematic diagram of an embodiment of the device of the present invention, 1-amplifier, 2-sealing device, 3-side plate, 4-die head, 5-center feed port, 11-motor, 12-bearing, 13 -screw, 14-fixed frame, 15-nut block, 16-plug gun, 17-hollow screw, 18-side plate, 19-side inlet, 20-plastic gasket, 21-deflector, 22- Buffer flow channel, 23-die lip flow channel, side plates 3 are fastened on both sides of the die head 4, each side plate 3 is equipped with an amplitude modulator 1 and a sealing device 2, and the amplitude modulator 1 includes a screw rod 13, a nut puller Block 15, plug gun 16, fixed frame 14, bearing 12 and motor 11, bearing 12 is installed at screw mandrel 13 two ends, be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com