Method for automatically partitioning complicated section zone during additive manufacturing

A regional and complex technology, applied in the field of additive manufacturing, to achieve the effect of reducing the number of knife lifts and improving printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] (1) Discrimination of region segmentation points:

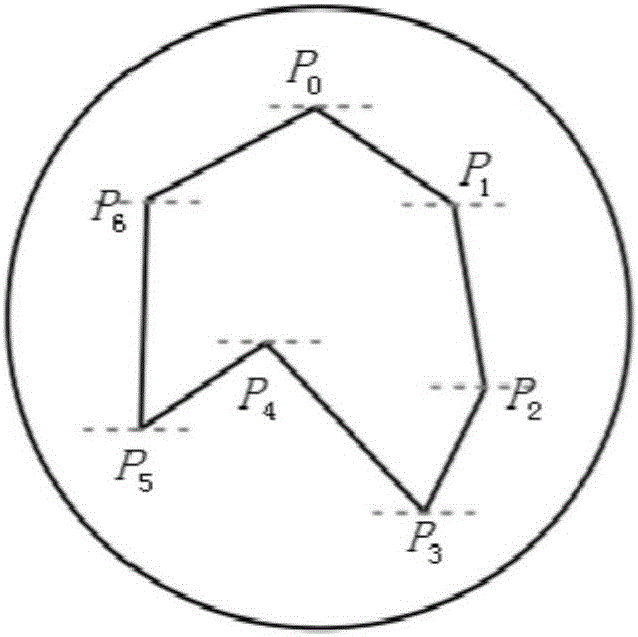

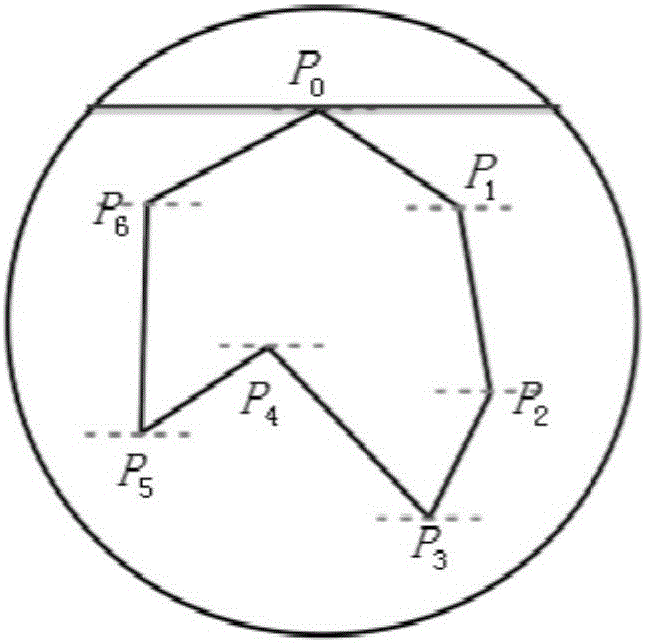

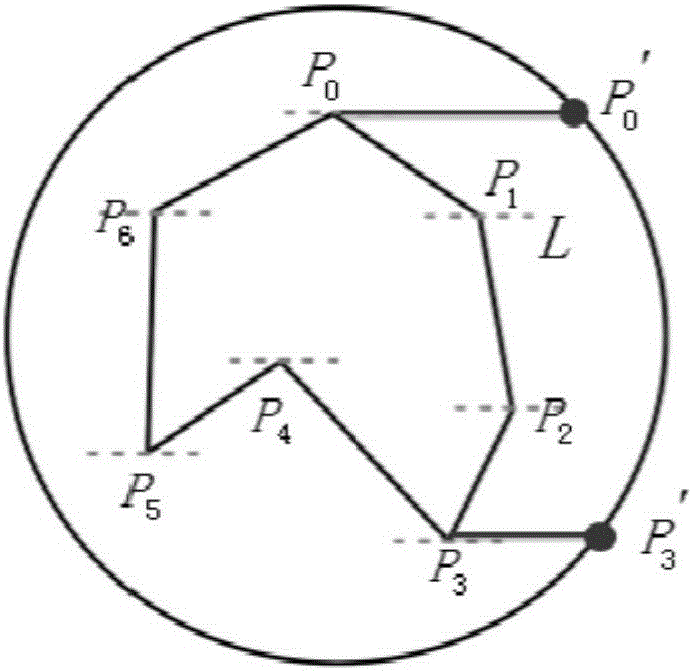

[0023] figure 1 In the hole structure whose inner contour is a concave polygon, it consists of P 0 ~P 6 A total of seven coordinate points are formed, and the line connecting two data points with adjacent subscript index values constitutes the edge of the inner contour. According to the above region segmentation point discrimination algorithm, by P 0 ~P 6 Each vertex of the inner contour is examined in turn. to examine P 0 For example, P 0 The next point of the adjacent index value is P 1 , the y coordinate values of the two are not equal, that is, P 0 P 1 Not a horizontal edge. with P 0 The adjacent inner contour vertices are P 1 ,P 6 , over P 0 Points to draw a horizontal line L, such as figure 2 , it is not difficult to find that P 1 ,P 6 Two points are on the same side of the horizontal line L, then P 0 as a possible split point. At this point, first from P 0 Point out the ray to the right,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com