Automobile taillight

A technology for rear taillights and automobiles, which is applied to vehicle components, optical signals, signal devices, etc. It can solve problems such as screw leakage, cracks, and affect the effect of loading and matching, so as to prolong the service life, improve weather resistance, and improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to deepen the understanding of the present invention, the following further describes the present invention with reference to the accompanying drawings and embodiments. The embodiments are only used to explain the present invention and do not limit the protection scope of the present invention.

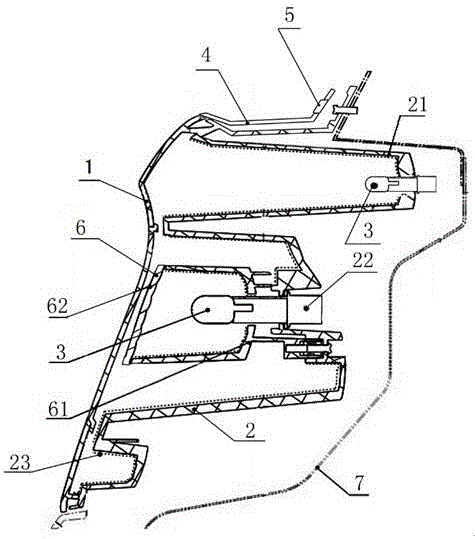

[0011] by figure 1 It is known that a rear taillight of an automobile includes a lampshade 1 and a lamp housing 2. The lampshade 1 is connected with the lamp housing 2 to form a cavity. The lamp housing 2 is provided with one or more functional reflectors 21, and the functional reflectors 21 There is a light source mounting seat 22, and the light source 3 is sealed and mounted on the light source mounting seat 22. The inner surface of the lamp housing 2 is provided with an aluminum plating layer 23; one side of the lamp housing 2 is provided with an integrated mounting plate 24, the mounting plate 24 A guard plate 4 is fixedly installed on the upper part. The height of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com