A distributed resource utilization system and method for sulfur in coking industry

A distributed resource and resource-based technology, applied in the chemical industry, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of unsuitable coke oven denitration, large land occupation and energy consumption, and high denitration cost. Conducive to efficient utilization of efficiency, reduction of energy consumption and investment, and avoidance of ineffective cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

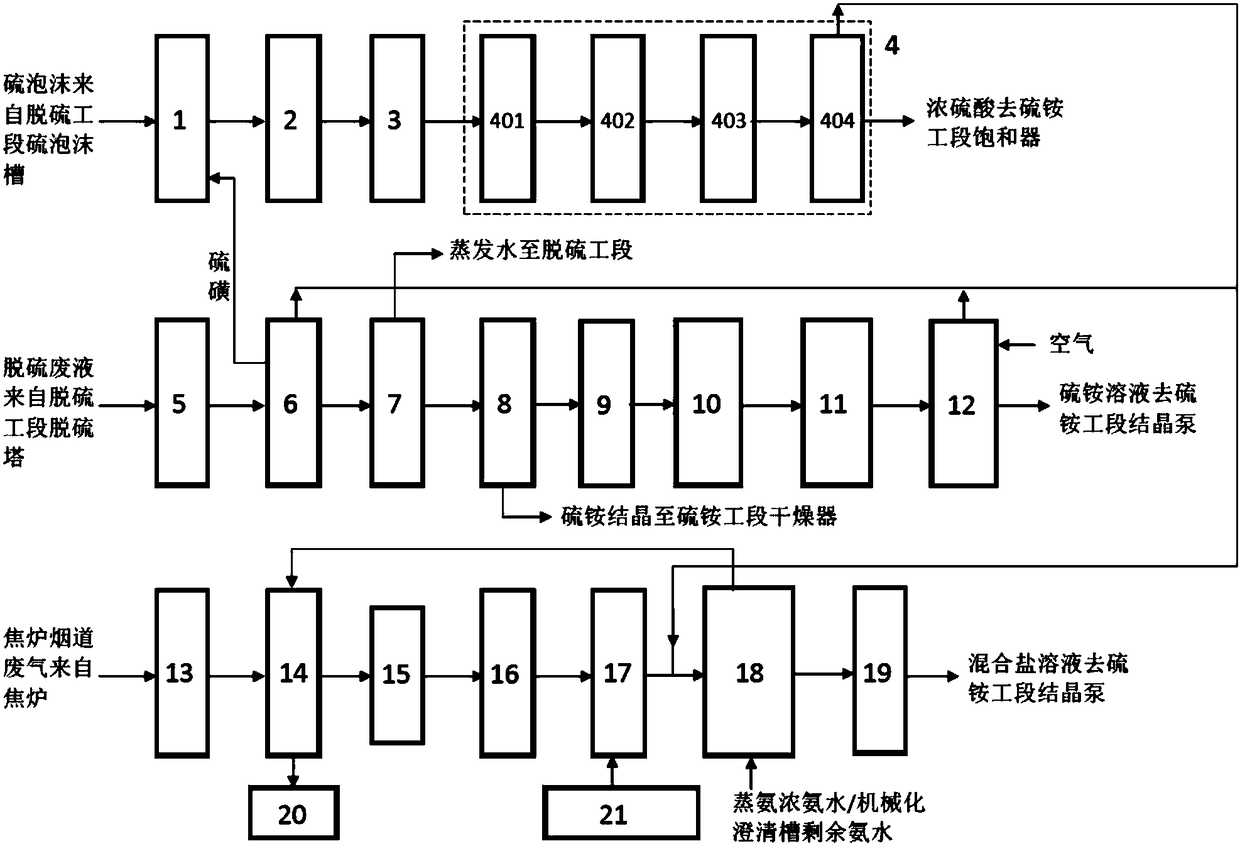

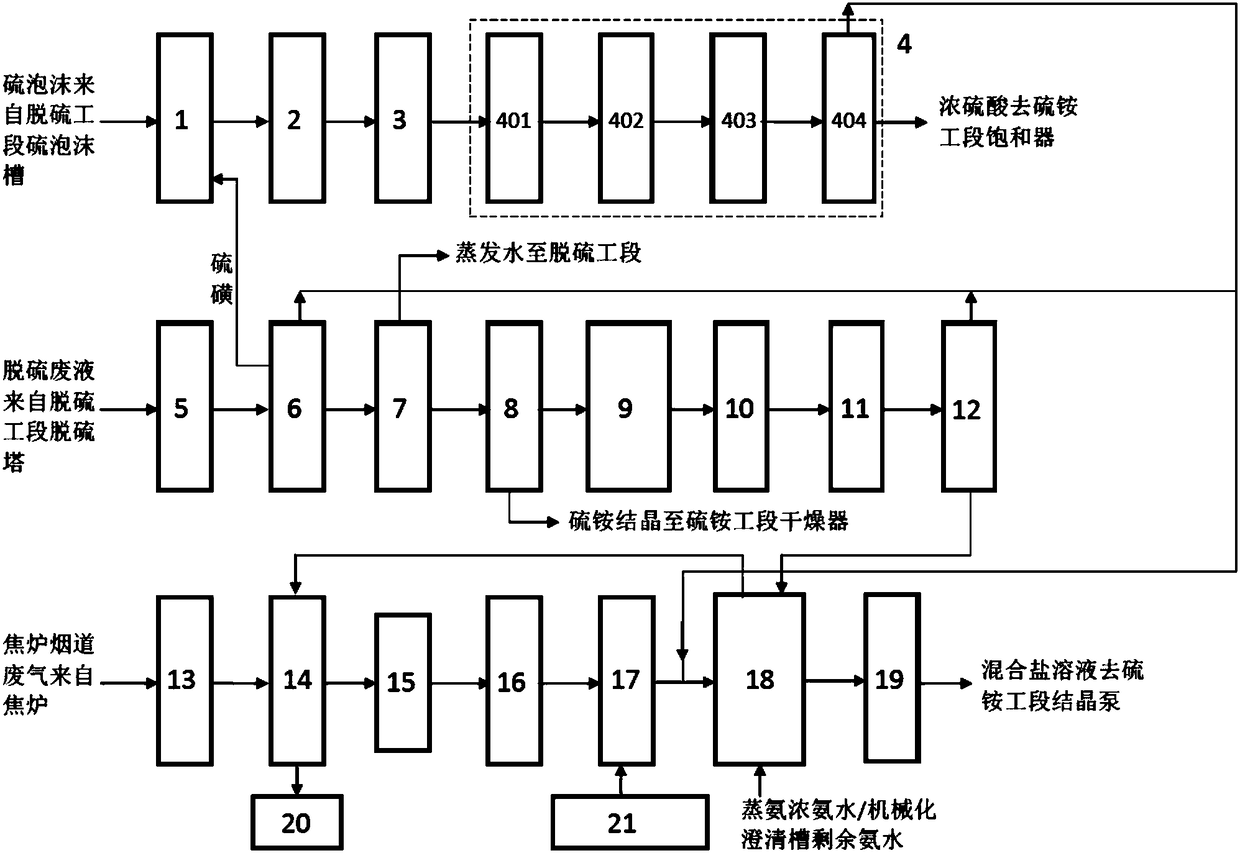

[0046] The sulfur foam after desulfurization and regeneration of coke oven gas, after simple standing and phase separation in the sulfur foam tank, extracts about 1.25-1.75t / h of sulfur foam from the lower part of the sulfur foam tank, of which the sulfur content is 40%-50%. Sent to the continuous sulfur melting purifier 1, which adopts the method of melting and purifying, first passes through the bubble breaking section, and the temperature is controlled at 70-80°C, so that the air bubbles in the sulfur foam are broken, the sulfur particles are precipitated and separated, and the air bubbles are broken. The gas is released from the top of the continuous sulfur melting purifier 1, and the release rate is determined by the gas phase pressure in the continuous sulfur melting refiner 1, usually the pressure is controlled at 2-5kg / cm 2 , higher than 5kg / cm 2 Then open the exhaust valve. Then it enters the deliquoring section and is heated to 150-160°C to melt the sulfur particles...

Embodiment 2

[0048] 330kg / h of purified sulfur with a purity of 95%-99% is sent into the sulfur incinerator 2 through a mechanical spray gun, and burned at 1100-1200°C to generate SO 2 The high-temperature gas with a concentration of 9% to 10% is cooled to 400 to 480°C after the waste heat is recovered by the first waste heat boiler 3 to generate medium and high pressure steam, and then the SO 2 After the concentration reaches 9%-9.5%, the temperature is adjusted to 380-450°C, it enters the second conversion and second absorption unit 4 to make acid. First enter the primary converter 401 at 110-150KPa (absolute pressure), 450-580°C, and perform the first conversion in the presence of a catalyst, and the gas after the first conversion enters the primary absorption tower 402 and absorbs it with concentrated sulfuric acid SO 3 Afterwards, enter secondary reformer 403 again at 110~150KPa (absolute pressure), 450~580 ℃, under the situation that catalyst exists, carry out secondary transformati...

Embodiment 3

[0051] 50t / d of desulfurization waste liquid regularly discharged from the coke oven gas desulfurization section contains 120-160g / L ammonium thiocyanate, 50-80g / L ammonium thiosulfate and 50-60g / L ammonium sulfate. First enter the decolorizer 5, add activated carbon under the condition of 60-80°C and 110-150KPa (absolute pressure) for decolorization, filter out the activated carbon that adsorbs colored impurities, and then send it to the thiooxidizer 6, at 50-90°C, 110 ~ 150KPa (absolute pressure), add catalyst, feed oxygen under the condition of residence time 1 ~ 3h, oxidize the ammonium thiosulfate into ammonium sulfate, and the tail gas generated during the thiooxidation process is passed into the desulfurization and denitrification integrated tower together deal with. The generated sulfur is filtered while it is hot, and sent to the continuous melting sulfur purifier 1 to participate in the subsequent process of burning sulfur to produce acid. Ammonium sulfate solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com