Method for growing anaerobic granular sludge for protein wastewater treatment

A technology for anaerobic granular sludge and protein wastewater, which is applied in the food industry wastewater treatment, anaerobic digestion treatment and other directions, can solve the problem of large consumption of sludge particles, and achieve the effect of increasing the content of granular sludge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

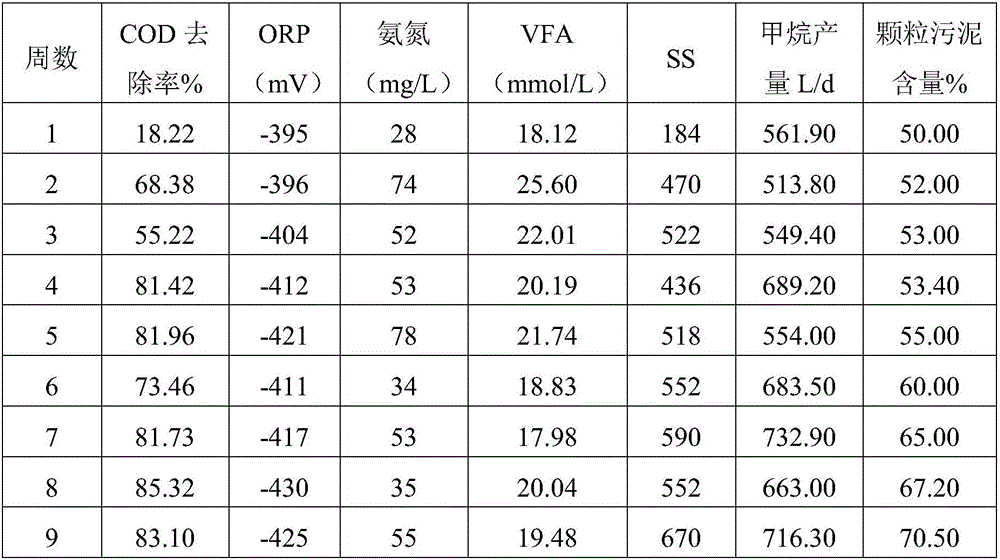

Embodiment 1

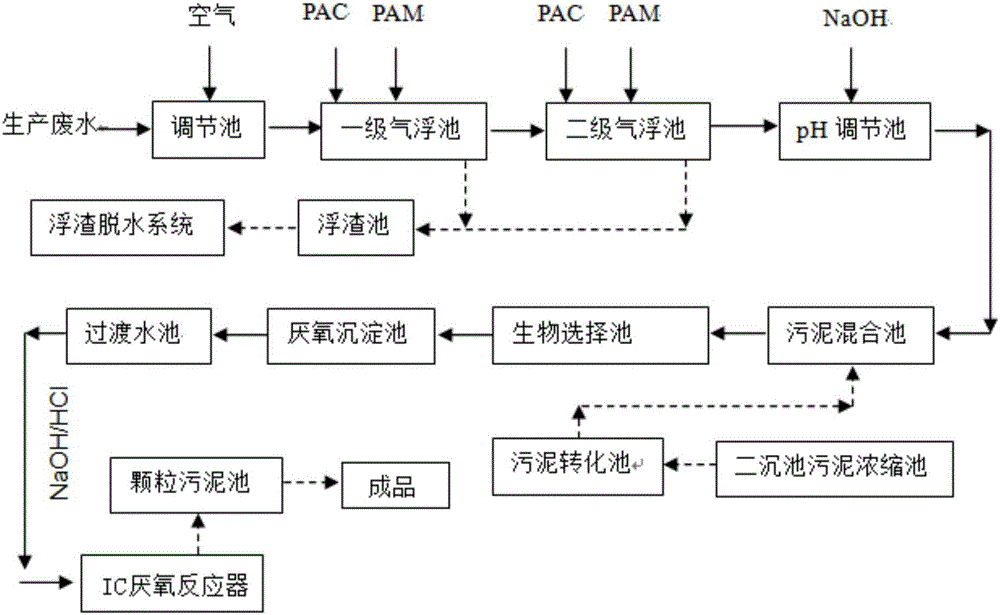

[0029] The growth method of the anaerobic granular sludge that is used for protein wastewater treatment described in the present embodiment, comprises the steps:

[0030] (1) Collect the wastewater of the soybean protein production process, add it to the adjustment tank for homogenization and equalization treatment, the bottom of the adjustment tank is provided with perforations, and perform aeration during the homogenization and equalization process;

[0031] (2) Transport the treated waste water to the primary air flotation tank, and add PAC and 0.02 wt% PAM accounting for 0.3wt% of the waste water to remove pollutants such as SS in the waste water by air flotation; The scum enters the scum tank and is dried through the scum dehydration system;

[0032] (3) Transport the waste water after the above-mentioned air flotation to the secondary air flotation tank, add PAC and 0.02 wt% PAM accounting for 0.1wt% of the waste water, further remove pollutants such as SS in the waste w...

Embodiment 2

[0038] The growth method of the anaerobic granular sludge that is used for protein wastewater treatment described in the present embodiment, comprises the steps:

[0039] (1) Collect the wastewater of the soybean protein production process, add it to the adjustment tank for homogenization and equalization treatment, the bottom of the adjustment tank is provided with perforations, and perform aeration during the homogenization and equalization process;

[0040] (2) Transport the treated waste water to the primary air flotation tank, and add PAC and 0.01 wt% PAM accounting for 0.4wt% of the waste water to remove pollutants such as SS in the waste water by air flotation; The scum enters the scum tank and is dried through the scum dehydration system;

[0041] (3) Transport the waste water after the above-mentioned air flotation to the secondary air flotation tank, add PAC and 0.005 wt% PAM accounting for 0.3wt% of the waste water, further remove pollutants such as SS in the waste ...

Embodiment 3

[0047] The growth method of the anaerobic granular sludge that is used for protein wastewater treatment described in the present embodiment, comprises the steps:

[0048](1) Collect the wastewater of the soybean protein production process, add it to the adjustment tank for homogenization and equalization treatment, the bottom of the adjustment tank is provided with perforations, and perform aeration during the homogenization and equalization process;

[0049] (2) Transport the treated wastewater to the primary air flotation tank, and add PAC and 0.015wt% PAM accounting for 0.35wt% of the wastewater, and remove pollutants such as SS in the wastewater by air flotation; The scum enters the scum tank and is dried through the scum dehydration system;

[0050] (3) Transport the waste water after the above-mentioned air flotation to the secondary air flotation tank, add PAC and 0.01 wt% PAM accounting for 0.2wt% of the waste water, further remove pollutants such as SS in the waste wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com