Thermal spraying fixture protective coating, protective method and application

A technology of tooling fixtures and protective coatings, which is applied in the direction of surface coating liquid devices, coatings, and pre-treated surfaces to achieve the effect of easy peeling off and adhesion strength protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Mix high temperature resistant paint W61-500 and 180 mesh graphite powder at a volume ratio of 1:1, and put in an appropriate amount of curing agent as required (the ratio of paint and curing agent should be carried out according to the instructions of the paint manufacturer), and stir evenly. Then add an appropriate amount of diluent according to the viscosity to dilute, and stir again evenly to obtain the protective coating for thermal spraying fixtures.

[0038] After the protective surface of the thermal spray fixture is cleaned and degreased and sand blasted, brush the protective coating of the thermal spray fixture on the surface of the thermal spray fixture, dry it in a ventilated place or cure the coating by other means.

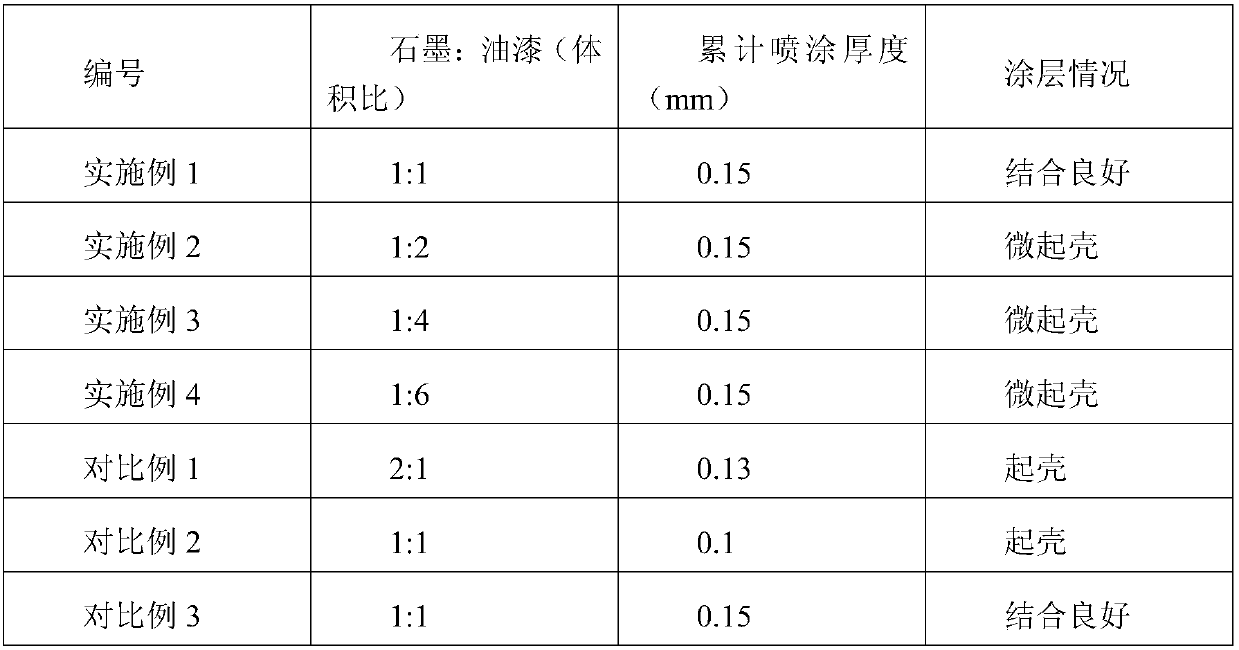

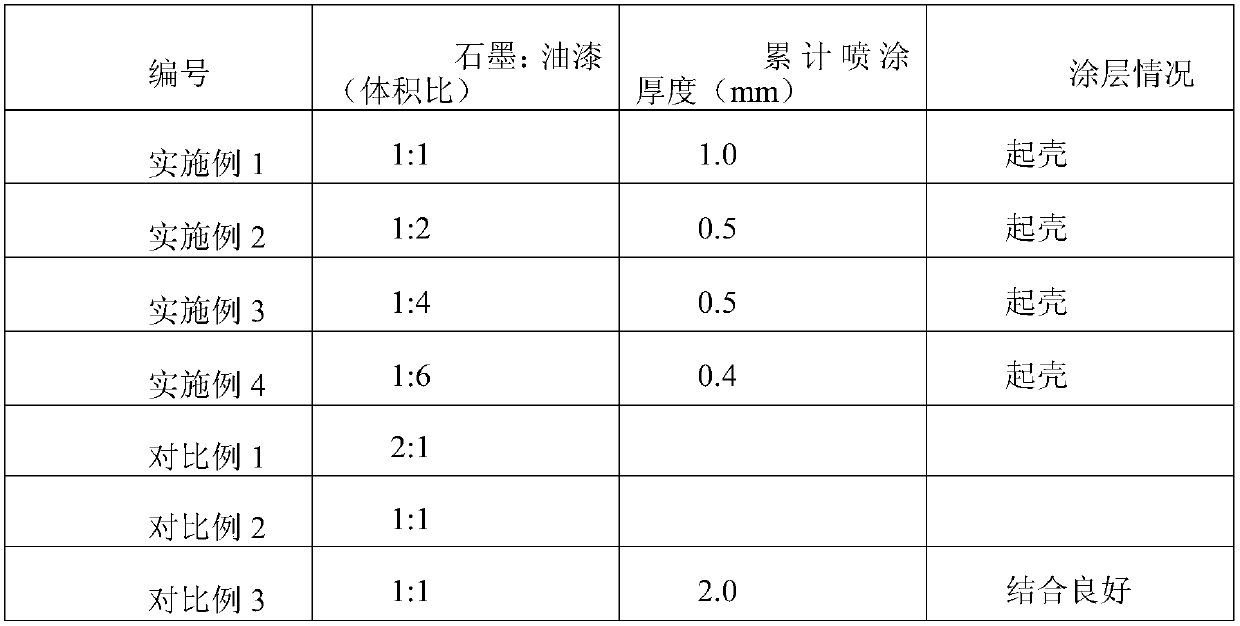

[0039] Use oxyacetylene flame spraying for the protected thermal spraying fixtures. First, spray aluminum-clad nickel powder (priming layer) as shown in Table 1. The spraying thickness is 0.15mm. At this time, the protective coating is well com...

Embodiment 2

[0041] Mix high temperature resistant paint W61-500 and 180 mesh graphite powder at a volume ratio of 2:1, and put in an appropriate amount of curing agent as required (the ratio of paint and curing agent should be carried out according to the instructions of the paint manufacturer), and stir evenly. Then add an appropriate amount of diluent according to the viscosity to dilute, and stir again evenly to obtain the protective coating for thermal spraying fixtures.

[0042]After the protective surface of the thermal spray fixture is cleaned and degreased and sand blasted, brush the protective coating of the thermal spray fixture on the surface of the thermal spray fixture, dry it in a ventilated place or cure the coating by other means.

[0043] Use oxyacetylene flame spraying for the protected thermal spraying fixtures. First, spray aluminum-clad nickel powder (priming layer) as shown in Table 1. The spraying thickness is 0.15mm. At this time, the protective coating and the ther...

Embodiment 3

[0045] Mix high-temperature-resistant paint WEH61884 with 160 mesh graphite powder at a volume ratio of 4:1, and put in an appropriate amount of curing agent as required (the ratio of paint and curing agent should be carried out according to the instructions of the paint manufacturer), stir evenly, and then Add an appropriate amount of thinner to dilute the viscosity, and stir again to get the protective coating for thermal spraying tooling and fixtures.

[0046] After the protective surface of the thermal spray fixture is cleaned and degreased and sand blasted, brush the protective coating of the thermal spray fixture on the surface of the thermal spray fixture, dry it in a ventilated place or cure the coating by other means.

[0047] Use oxyacetylene flame spraying for the protected thermal spraying fixtures. First, spray aluminum-clad nickel powder (priming layer) as shown in Table 1. The spraying thickness is 0.15mm. At this time, the protective coating is well combined wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com