Water-based all-purpose adhesive and method for preparing same

An all-purpose adhesive, water-based technology, applied in applications, coatings, inks, etc., can solve the problems of human body injury, environmental pollution, and smelly working environment, achieve good stability, wide application, and solve flammable problems. Effect

Inactive Publication Date: 2010-08-18

唐浩

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to meet the needs of interior decoration, environmentally friendly all-purpose adhesives with styrene-butadiene rubber (SBS glue) and triphenyl solvents have appeared on the market, as disclosed in Chinese patent ZL 02115077.X (publication date 2003.10.29, publication number CN1451709A) "Multipurpose Universal Decorative Adhesive", Chinese Patent ZL02115167.9 (publication date 2003.11.05, publication number CN1453325A) disclosed "high-viscosity SBS non-toxic universal decorative glue" and Chinese patent ZL200410037322.X (publication date 2005.01. 26. The "Environmentally Friendly Universal Adhesive and Its Production Method" disclosed by Publication No. CN1570006A) is a product made of SBS as the main component and processed with various mixed solvents such as ethyl acetate and solvent naphtha. Although it does not contain Triphenyl is relatively harmful, but the inherent flammability and explosiveness of solvent-based glue has not been really solved. The volatilization of organic solvents in glue will also cause environmental pollution, and the working environment has a strong smell, and organic solvents are also harmful to the human body. Harmful, easy to form occupational diseases, not conducive to the health of workers

There are also various water-based adhesives in the prior art, such as water-based adhesives such as vinyl acetate homopolymer emulsions and acrylate copolymer emulsions, but all of them can only meet part of the use requirements, and there are deficiencies in one way or another. There is also a lack of a water-based universal adhesive that is widely applicable and easy to use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Login to View More

Abstract

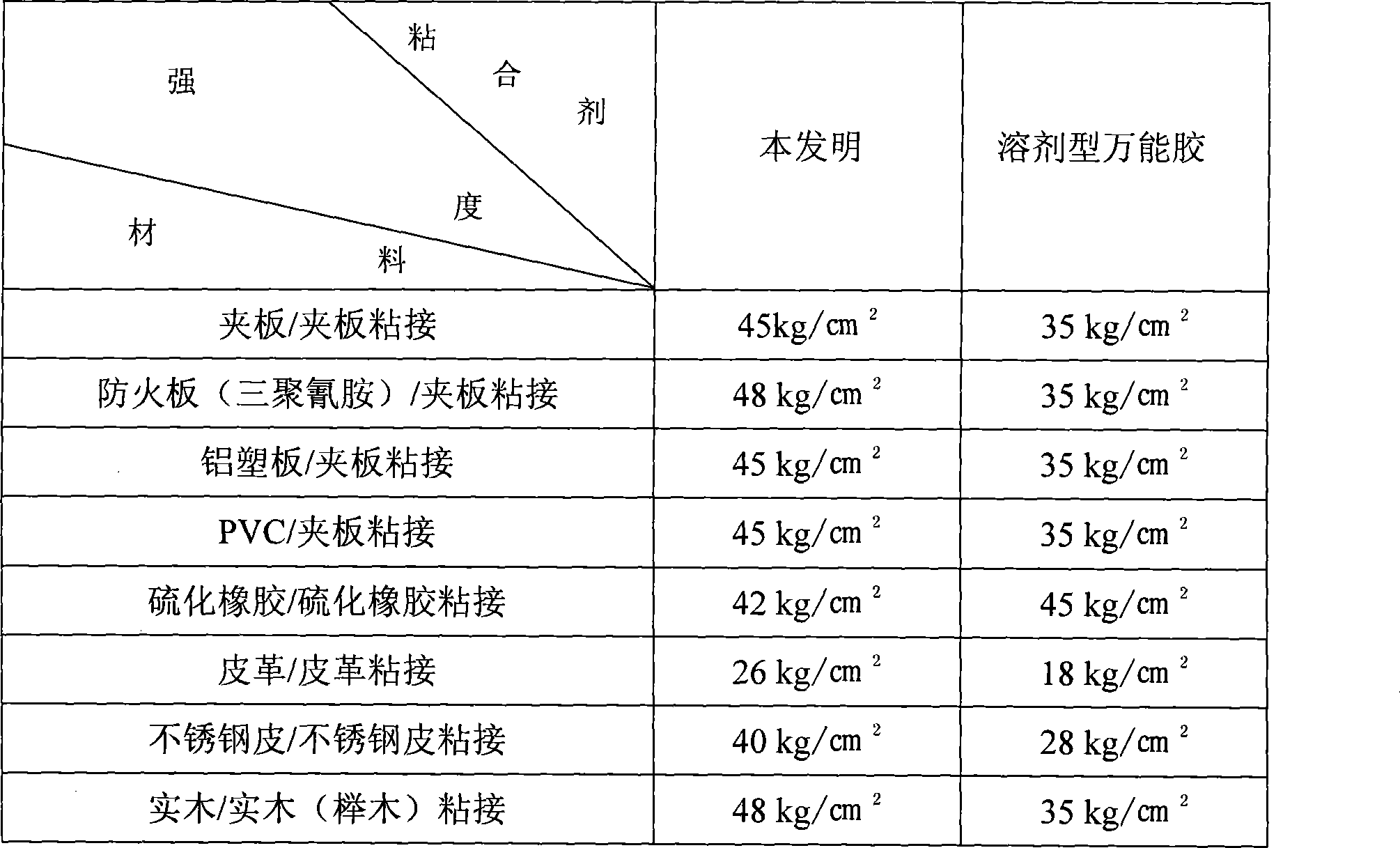

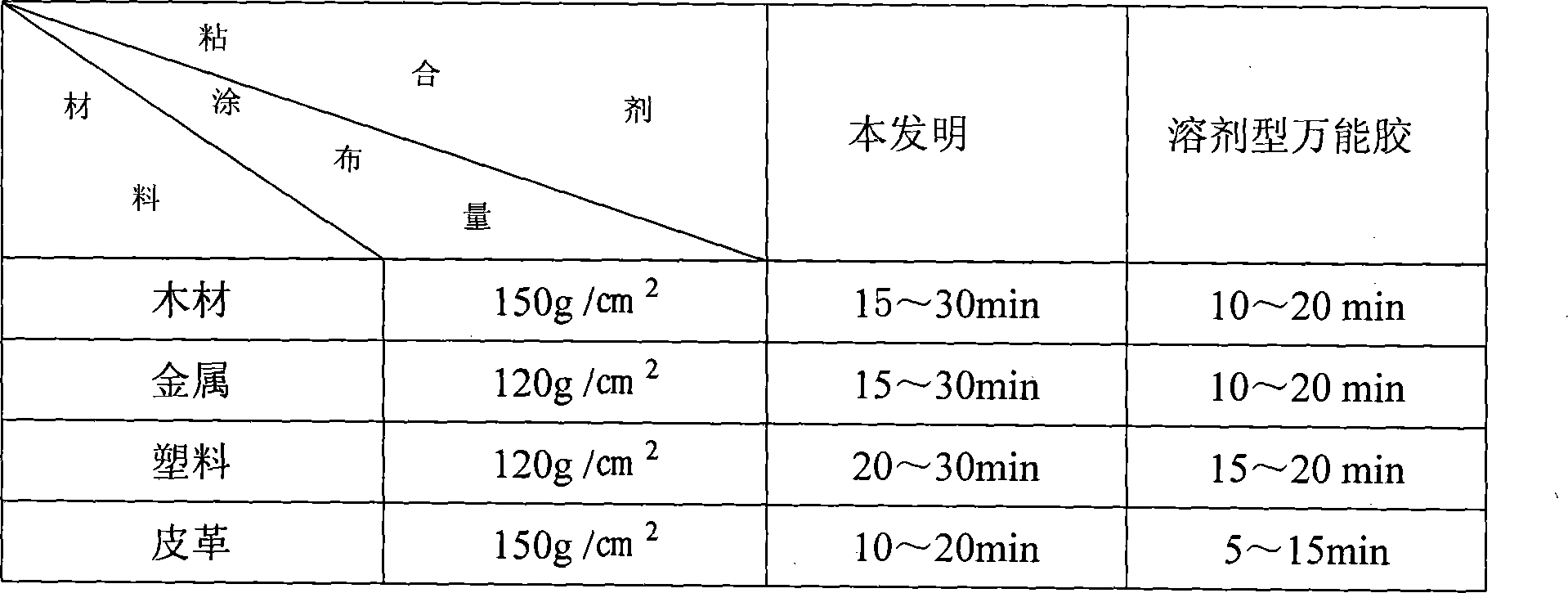

The invention discloses a water-based all purpose adhesive and the preparation method, which belongs to the field of water-based adhesive, the technical proposal is a copolymer emulsion of 120 to 300 portions of vinyl acetate, 15 to 50 portions of organic silicon monomer with unsaturated double bond, 60 to 150 portions of ethylene tertiary carbonate, 80 to 120 portions of butyl acrylate, 90 to 150 portions of iso-octyl acrylate, 5 to 15 portions of acrylic acid; the emulsion also comprises 20 to 80 portions of tackifying resin, 3 to 8 portions of sodium salt decocting mixture, 50 to 150 portions of plasticizer, 15 to 50 portions of polyvinyl alcohol, 2 to 8 portions of silane coupling agent, 8 to 12 portions of hydrochloric acid, 3 to 15 portions of anionic emulsifier and 3 to 12 portionsof nonionic emulsifier. The preparation method is that the mixed monomer is dropped by the manner of emulsion polymerization, and should be completed in three to five hours; warming up to 85 to 95 DEG C to cure for 40 to 60 minutes; then discharging and filtering and packaging after cooling down to 45 to 35 DEG C. The water-based all purpose adhesive has the advantages of convenient use, wide applicability, and can be used for the manufacturing of furniture, luggage and construction decoration.

Description

technical field The present invention relates to a water-based adhesive, more particularly, to a water-based all-purpose adhesive used for furniture, luggage manufacturing and building decoration, and also relates to a preparation method of the all-purpose adhesive. Background technique What we usually call all-purpose adhesive refers to a type of solvent-based adhesive commonly used in the building decoration and hardware maintenance industries. It is named because of its wide bonding range and convenient use. The main component of the early all-purpose glue is neoprene, which generally uses benzene, toluene and xylene as solvents, and is yellow liquid and viscous (commonly known as yellow glue), which can be used for wood, aluminum-plastic board, leather, artificial leather, plastic, rubber, Bonding of hard and soft materials such as metals. Since benzene, toluene and xylene are harmful to the body, they have been banned abroad, but they will not withdraw from the interio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09D131/04C09D11/06

Inventor 唐浩

Owner 唐浩

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com