Photocurable Adhesive Composition

An adhesive composition and light-curing technology, applied in the direction of non-polymer organic compound adhesives, ester copolymer adhesives, polymer adhesive additives, etc., can solve the problem of reduced bonding strength, poor surface curing, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0079]

[0080] A photocurable adhesive composition can be prepared by mixing each component. The mixing method is not particularly limited, and various metal and plastic containers, stirring blades, and stirrers can be used.

[0081]

[0082] The photocurable adhesive composition can be used for bonding arbitrary base materials 1 and arbitrary base materials 2 . Substrate 1 and substrate 2 may be the same substrate or different substrates. At least one of the base material 1 and the base material 2 may be a translucent member. Thereby, a cured resin layer can be formed by irradiating an energy ray (for example, an ultraviolet-ray) to a photocurable adhesive composition from the translucent member side. Examples of the translucent member include glass, (meth)acrylic resin, polyethylene terephthalate, polyethylene naphthalate, polycarbonate, polyimide, polyester, Cycloolefin polymers, etc.

[0083] The photocurable adhesive composition is preferably used for bonding a d...

Embodiment

[0106] Next, the present invention will be described in more detail by way of examples and comparative examples. The present invention is not limited by these Examples. The indications are parts by mass and % by mass unless otherwise specified.

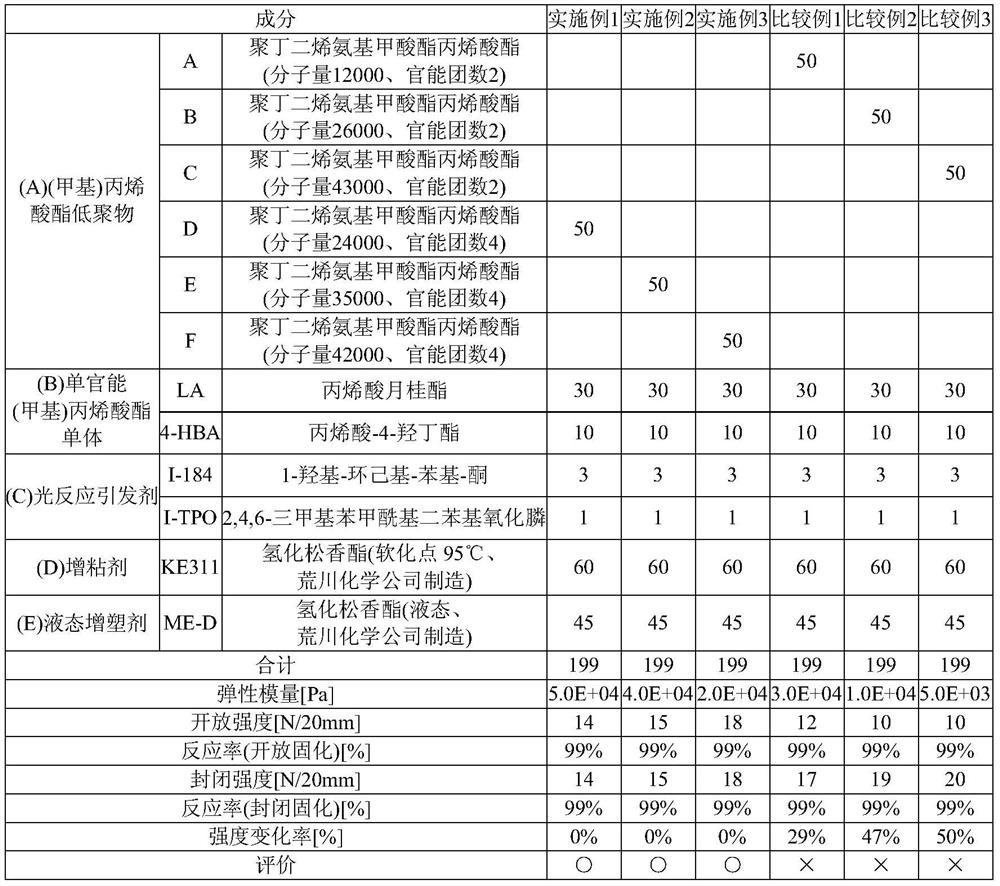

[0107]Each component of the compounding ratio shown in Table 1 was mixed uniformly, and the photocurable adhesive composition of the Example / Comparative Example was prepared. Here, polybutadiene urethane acrylate A-F was manufactured according to the following synthesis examples 1-6.

Synthetic example 1

[0108] Synthesis Example 1 (Manufacture of Polybutadiene Urethane Acrylate A)

[0109] Into a four-necked flask equipped with a thermometer, a stirrer, a dropping funnel, and a cooling tube with a drying tube, hydrogenated polybutadiene with hydroxyl groups at both ends (GI-3000, manufactured by Nippon Soda Co., Ltd., number average molecular weight 3,000, iodine value 21, hydroxyl value 25mgKOH / g ~ 35mgKOH / g) 300g (molecular weight calculated when the hydroxyl value is 30mgKOH: 0.080 mol), p-methoxyphenol 0.1g as a polymerization inhibitor, dilauric acid as a tin catalyst 0.1 g of dibutyltin (manufactured by Tokyo Fine Chemical Co., Ltd., L101). After raising the temperature to 80° C., 30.2 g (0.136 mol) of isophorone diisocyanate (Desmodur I, manufactured by Sumika Bayer Urethane) was uniformly added dropwise over 1 hour. After completion of the dropwise addition, reaction was performed at 80° C. for 3 hours. Thereafter, 11.5 g (0.080 mol) of 4-hydroxybutyl acrylate (4-HBA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com