Gemini surfactant nano-emulsion injection booster for oil field water injection and preparation method thereof

A Gemini surface and nanoemulsion technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of low success rate, short validity period, small acid penetration distance, etc., and achieve good injection performance, water phase The effect of improved permeability and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

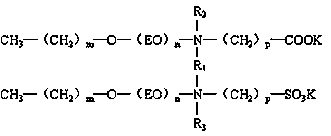

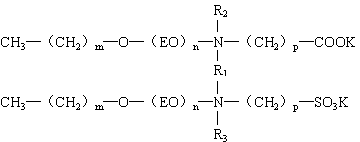

Method used

Image

Examples

Embodiment 1

[0017] Weigh 10.00g polyethoxylated fatty alcohol (structure is R-(O-C-C) x -OH, where R is a straight-chain alkyl group with 10 carbons, and x is 4), 10.00g of gemini surfactant and 18.00g of water were placed in a beaker, stirred on a magnetic stirrer at 200rpm for 30 min to make the system evenly stirred, At this point, slowly add 2.00 g of n-butanol dropwise to the beaker. After the dropwise addition is complete, keep the stirring speed of the magnetic stirrer at 200 rpm and stir for 30 minutes to obtain a clear and transparent nanoemulsion. The droplet size of the nanoemulsion was measured by ZetaPlus from Brookhaven Instrument Company, USA, and the average particle size of the prepared nanoemulsion was 28.62nm.

Embodiment 2

[0019] Weigh 4.00g polyethoxylated fatty alcohol (structure is R-(O-C-C) x -OH, where R is a straight-chain alkyl group with 10 carbons, and x is 9), 15.00g of gemini surfactant and 17.00g of water are placed in a beaker, and stirred on a magnetic stirrer at 200rpm for 30min to make the system evenly stirred. Slowly add 4.00g n-butanol dropwise to the beaker, after the dropwise addition is complete, keep the stirring speed of the magnetic stirrer at 200rpm, and stir for 30min to obtain a clear and transparent nanoemulsion. The droplet size of the nanoemulsion was measured by ZetaPlus from Brookhaven Instrument Company, USA, and the average particle size of the prepared nanoemulsion was 43.50 nm.

Embodiment 3

[0021] Weigh 12.00g polyethoxylated fatty alcohol (structure is R-(O-C-C) x -OH, wherein R is a straight-chain alkyl group with 10 carbons, and x is 8), 5.00g of gemini surfactant and 20.00g of water in a beaker, stirred on a magnetic stirrer at 200rpm for 30 min to make the system evenly stirred, At this point, slowly add 3.00 g of n-butanol dropwise to the beaker. After the dropwise addition is complete, keep the stirring speed of the magnetic stirrer at 200 rpm and stir for 40 minutes to obtain a clear and transparent nanoemulsion. The droplet size of the nanoemulsion was measured by ZetaPlus from Brookhaven Instrument Company, USA, and the average particle size of the prepared nanoemulsion was 37.82nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com