Electrode used for single crystal furnace body and use method thereof

A single crystal furnace and electrode technology, applied in the direction of crystal growth, chemical instruments and methods, furnaces, etc., can solve the problems of easy loss of components, softening of heating wires, increase in production costs, etc., to protect normal use and facilitate timely replacement. , the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

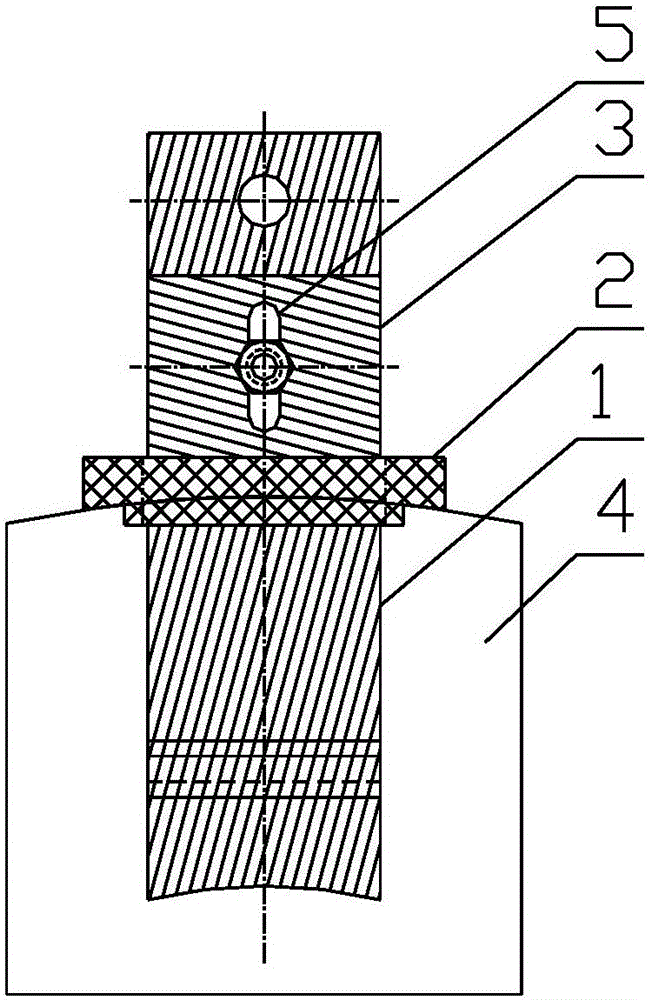

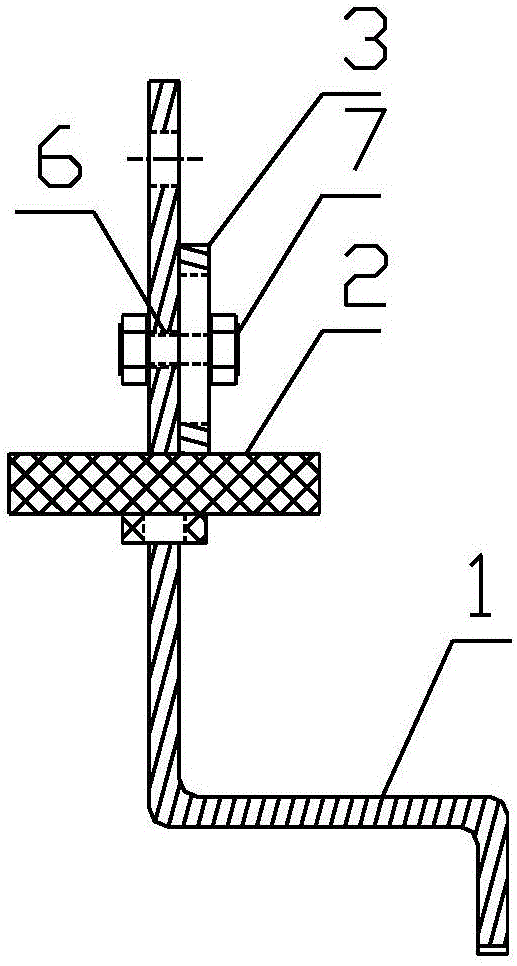

[0017] Attached below Figure 1-2 An electrode for a single crystal furnace body and its application method of the present invention are described in detail.

[0018] An electrode for a single crystal furnace body, the electrode includes an electrode body 1, an insulating sheet 2 and an electrode fixing sheet 3, wherein a part of the electrode body is arranged in the furnace body 4, and the other part extends out of the furnace body; the insulating sheet is fixed It is arranged on the furnace body and vertically connected with the electrode body extending out of the furnace body; a vertical strip-shaped adjustment hole 5 is provided on the electrode fixing sheet, and a mounting hole 6 matching the strip-shaped adjustment hole is provided on the electrode body. It is fastened to the electrode body and the spacer through the bolts 7 that pass through the vertical strip-shaped adjustment hole and the installation hole. The electrode fixing sheet is arranged parallel to the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com