Method for connecting pipeline into existing box culvert

A box culvert and pipeline technology, which is applied in the field of existing box culvert access pipelines, can solve the problems of box culvert waterproof failure, torsion, warping, rough interface, etc., to ensure safety and normal operation, facilitate management, and avoid water seepage the effect of the situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

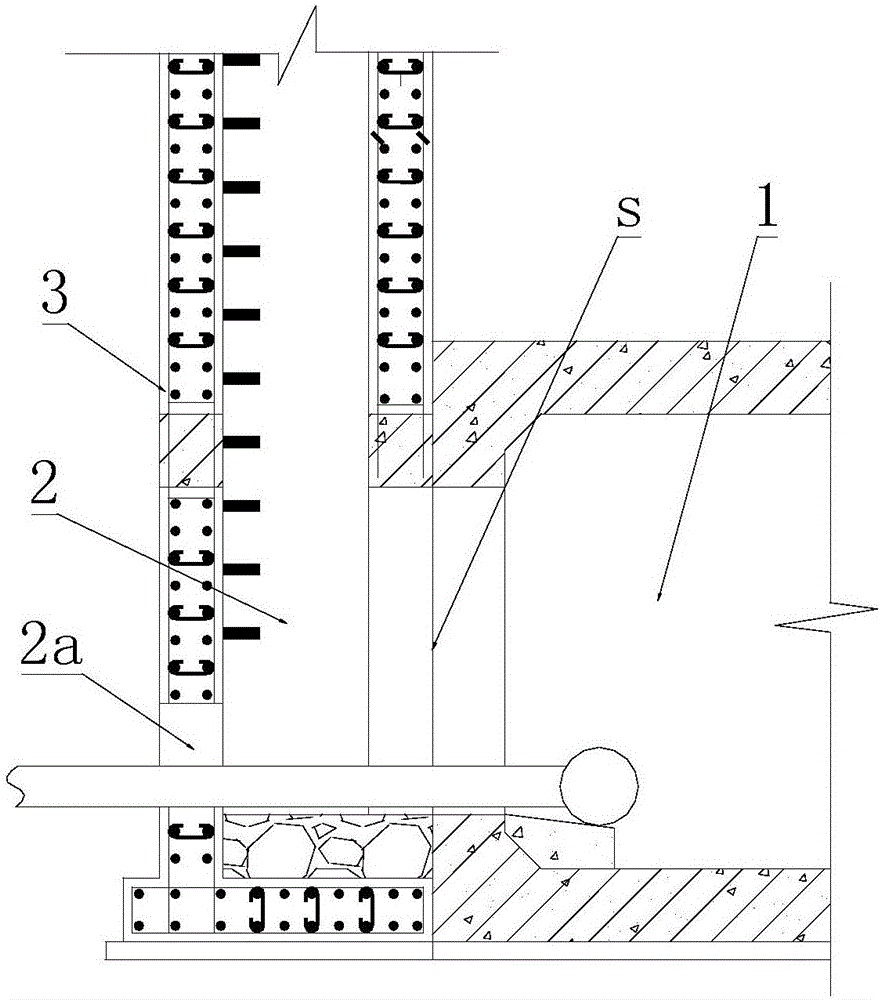

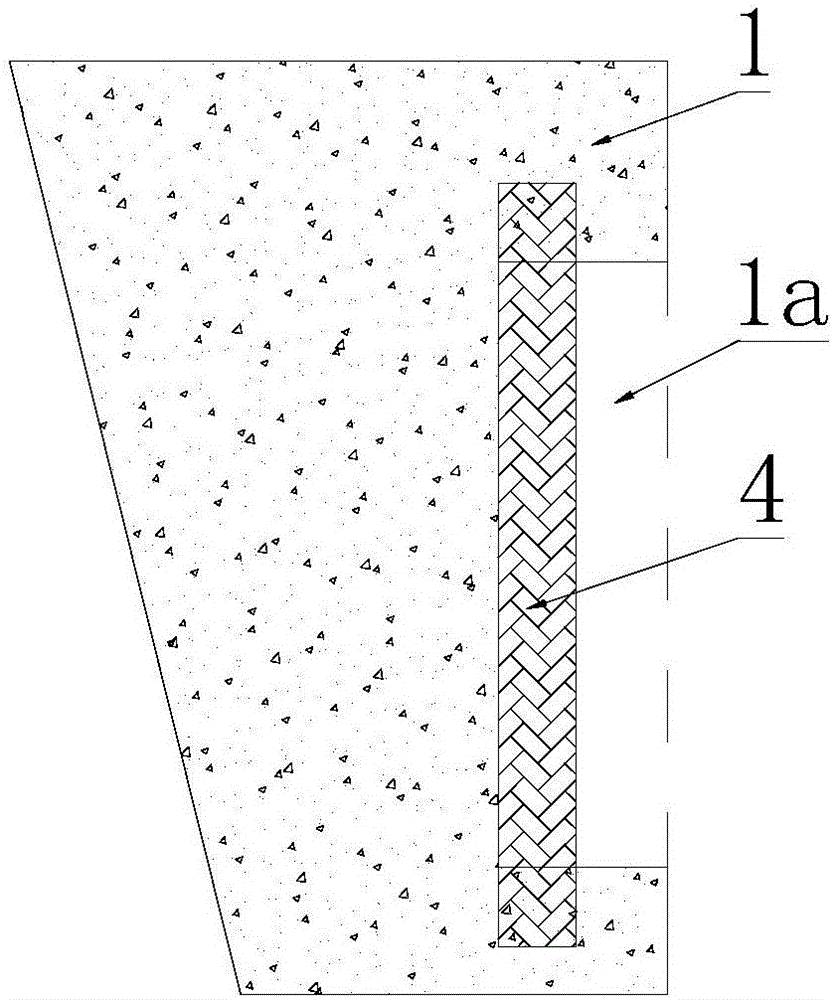

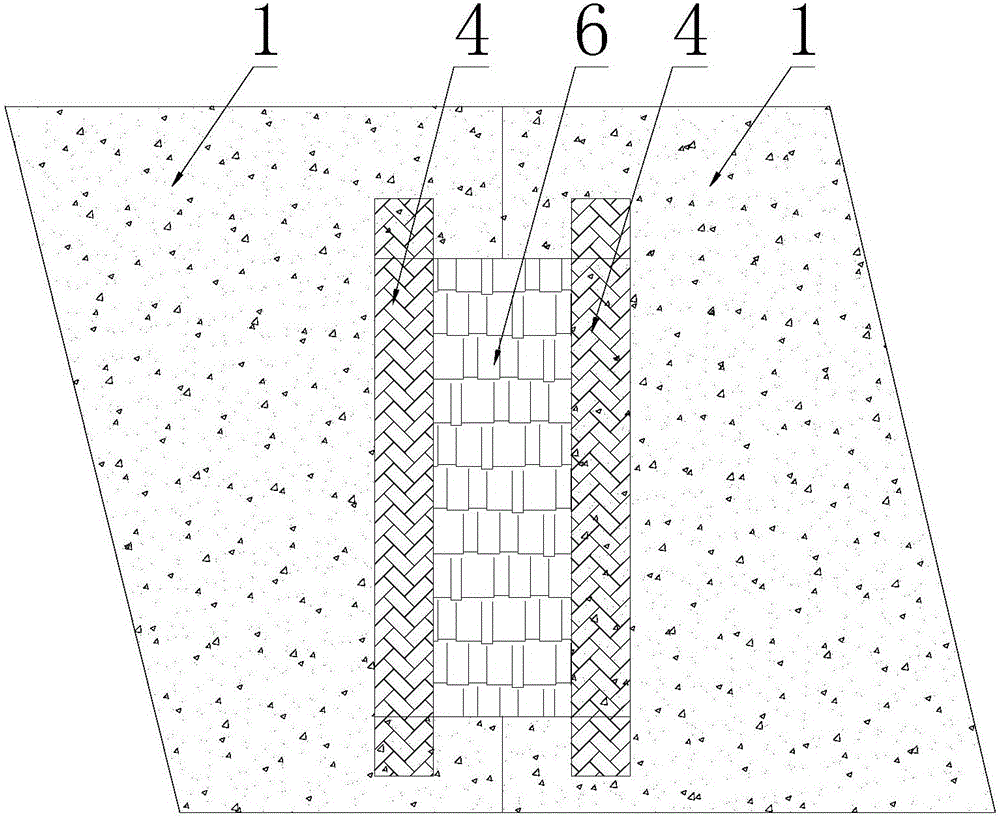

[0026] Such as Figure 1 to Figure 6 As shown, a method for connecting an existing box culvert to a pipeline is carried out in sequence as follows:

[0027] Step 1: Install an inspection well 2 vertically from the outside close to the box culvert 1, the box culvert 1 is pre-buried underground, and the outer wall of the inspection well 2 is coated with a waterproof layer 3, and the outer wall of the inspection well 2 is close to the The outer wall of the box culvert 1;

[0028] Step 2, setting a horizontal inspection passage s between the box culvert 1 and the inspection well 2, and communicating the two ends of the inspection passage s with the box culvert 1 and the inspection shaft 2 respectively;

[0029] Step 3, setting an inlet 2a on the side wall of the inspection well 2, extending the pipeline from the inlet 2a into the inspection well 2, and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com