Sponge urban rainwater seepage wells adopting building rubbish as built-in materials and manufacturing method

A construction waste and sponge city technology, applied in construction, chemical instruments and methods, water supply devices, etc., can solve the problems of high cost of sand and gravel materials, high cost of sand and gravel seepage wells, and reduce the pressure of municipal drainage systems and surface runoff , to avoid the effect of urban waterlogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

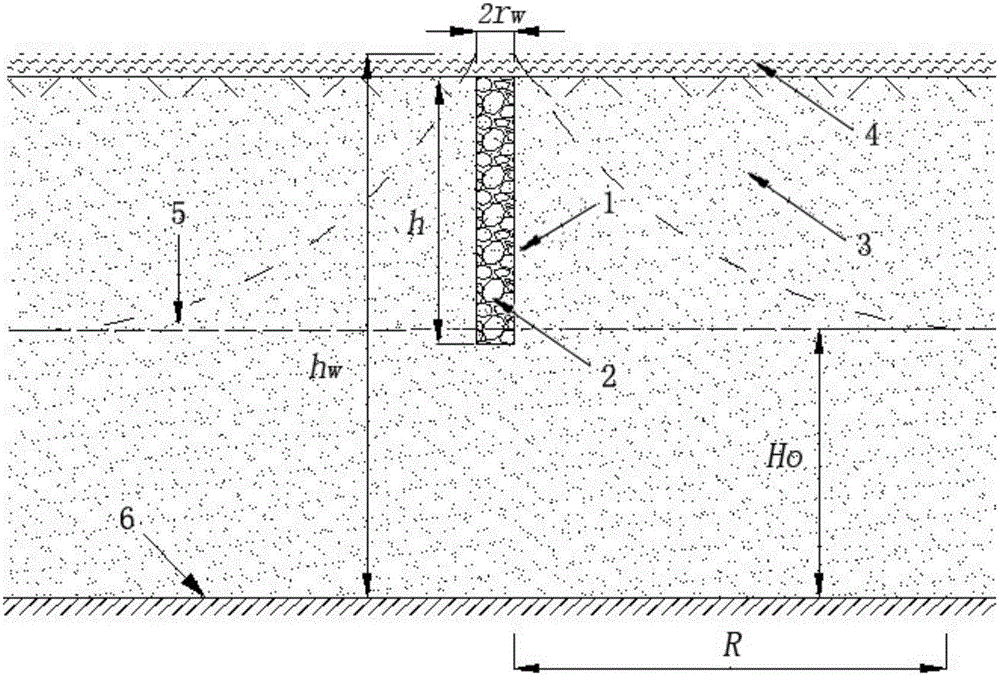

[0014] The construction waste of the present invention is described as the sponge city rainwater infiltration well structure of built-in material in conjunction with accompanying drawing.

[0015] Such as figure 1 As shown, the construction waste of the present invention is used as a sponge city rainwater infiltration well with built-in materials. Water permeability, enhance the groundwater conservation performance of the soil layer, the rainwater infiltration well is a plurality of, each rainwater infiltration well includes the infiltration well hole 1, the broken construction waste filling material 2 in the infiltration well hole and the surrounding soil 3; the infiltration well The hole 1 is placed in the surrounding soil 3, and the broken construction waste filling material 2 is filled in the seepage hole 1; the aperture and depth of the seepage hole 1 are set differently according to the embedding environment, the aperture is 10cm-20cm, and the depth is 100cm- 300cm; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com