Steel bar connector capable of adjusting position on plane

A technology of steel bar connectors and planes, which is applied to structural elements, building components, building reinforcements, etc., can solve problems such as the inability to connect steel bars, slow assembly and construction progress, and heavy connection workload, so as to achieve simple and convenient connection methods and reduce The effect of labor intensity and work efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

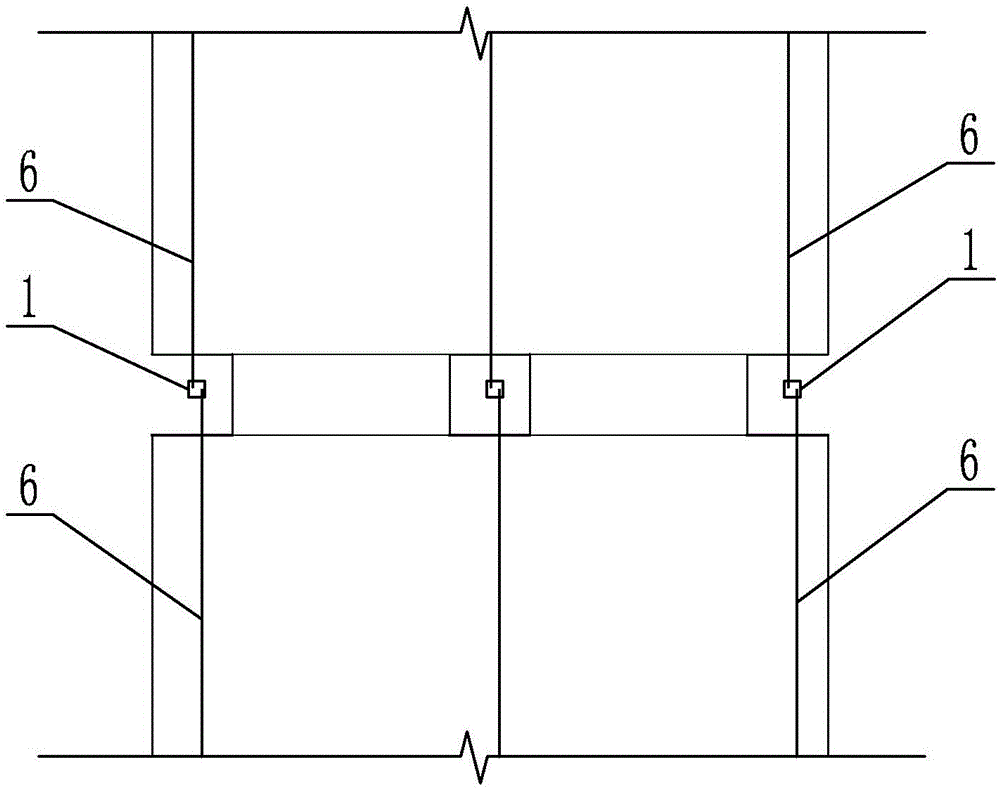

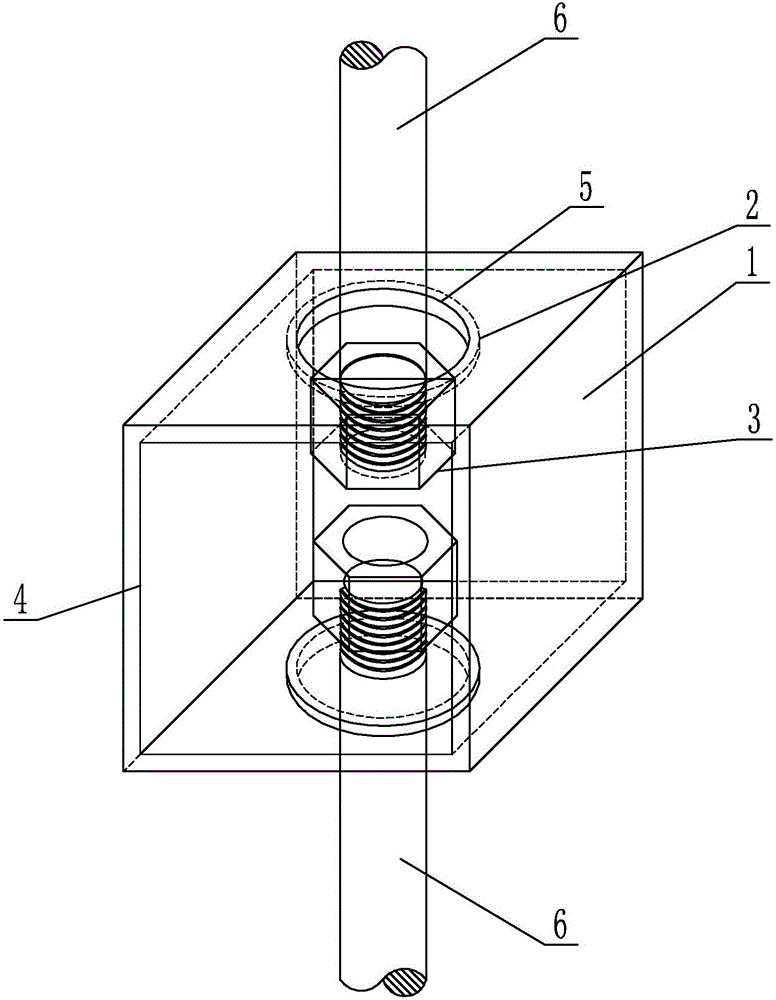

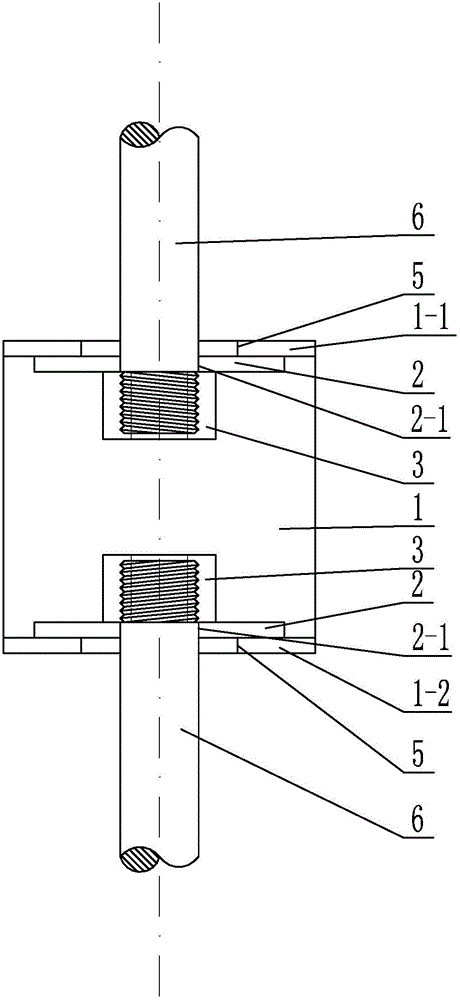

[0012] Specific implementation mode one: combine Figure 1 to Figure 5 This embodiment is described. A plane-adjustable steel bar connector described in this embodiment includes a connection frame 1, two limit bottom plates 2 and two nuts 3, and the upper end surface 1-1 and the lower end surface 1 of the connection frame 1 -2 are respectively arranged horizontally, the front end face and the rear end face of the connecting frame 1 are provided with an installation port 4, and the middle parts of the upper end face 1-1 and the lower end face 1-2 are respectively provided with a connecting through hole 5, and the reinforcing bars 6 on the upper part are vertical Inserted in the connection through hole 5 of the upper end surface 1-1, the lower steel bar 6 is vertically inserted in the connection through hole 5 of the lower end surface 1-2, and the ends of the upper and lower two steel bars 6 are respectively screwed with nuts 3, the nuts 3 Set in the connection frame 1, between ...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination Figure 2 to Figure 5 To describe this embodiment, the shape of the connecting frame 1 in this embodiment is rectangular. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

[0015] Such a design can change the shape and size of the connecting frame 1 as required, and the shape requires symmetry, which is easy to manufacture, and has a certain strength, which can ensure the bearing capacity of the joint.

specific Embodiment approach 3

[0016] Specific implementation mode three: combination Figure 2 to Figure 5 To describe this embodiment, the diameter of the connecting through hole 5 in this embodiment is larger than the outer diameter of the steel bar 6 . The undisclosed technical features in this embodiment are the same as those in the first or second specific embodiment.

[0017] This design can realize the in-plane movement of the steel bars 6, and when the longitudinal geometric center of the steel bars 6 is inconsistent with the geometric center of the connector, the steel bars 6 can be connected to the connectors respectively, thereby realizing the connection of the steel bars 6 at both ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com