Cased well tractor crawling device

A crawling device and tractor technology, applied in the field of cased well tractor crawling devices, can solve the problems of poor high temperature and high pressure resistance, large crawling device volume, poor wear resistance, etc., to reduce rotational friction and improve High transmission efficiency and strong obstacle-surpassing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

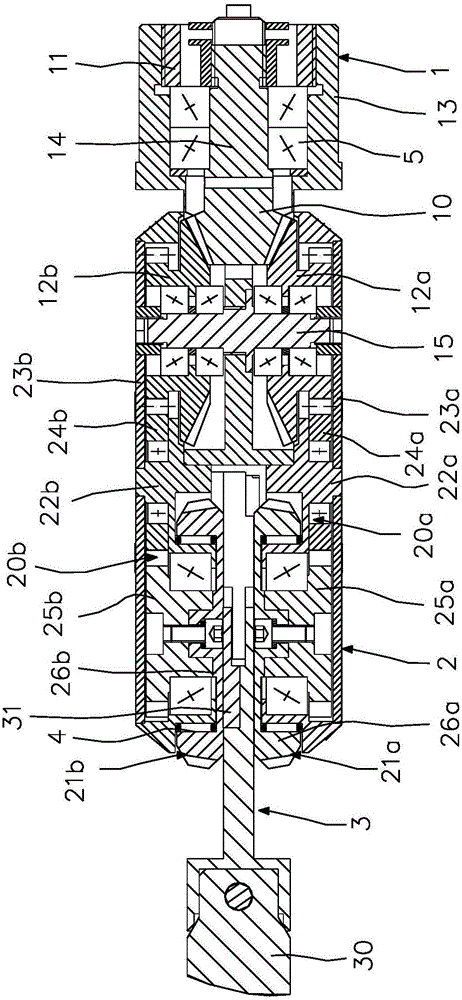

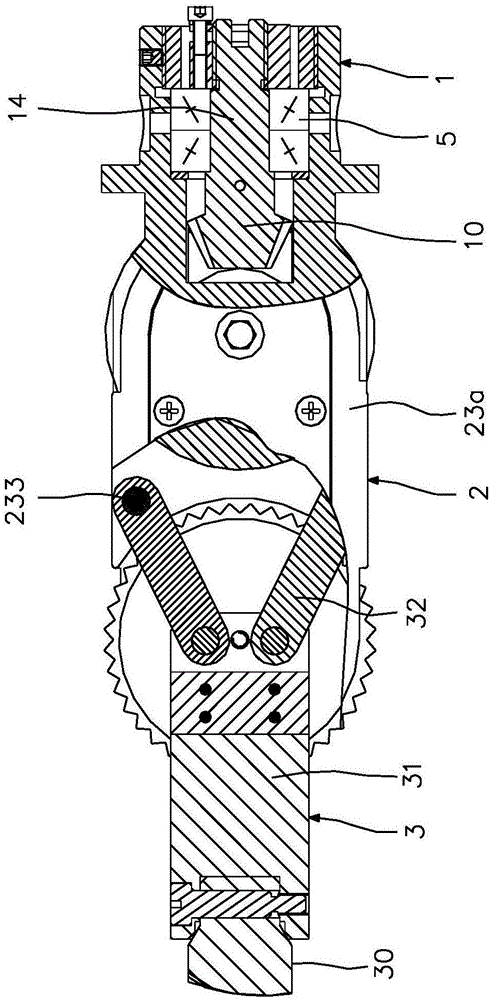

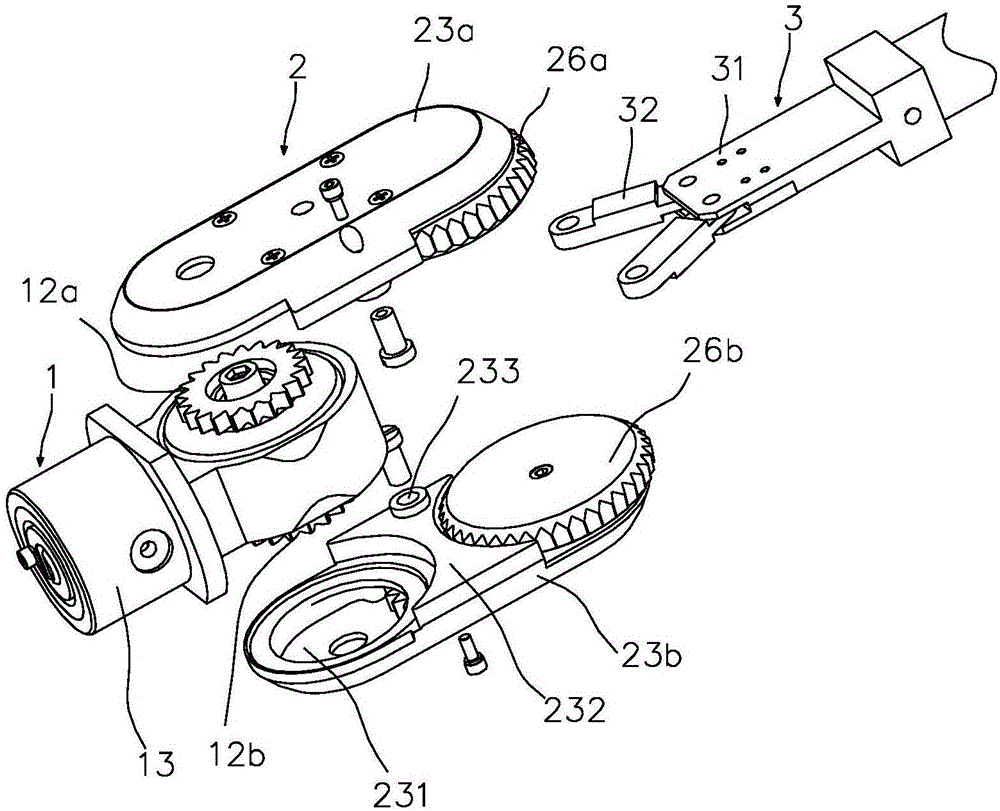

[0047] see Figure 1 to Figure 8 As shown, the embodiment of the present invention provides a cased well tractor crawling device for crawling inside the casing 6, including:

[0048] Gear sleeve assembly 1, which includes a driving bevel gear 10, a gear sleeve 13, a vertical shaft 14, a horizontal shaft 15, a first driven bevel gear 12a and a second driven bevel gear 12b, and the gear sleeve 13 is sleeved on the vertical shaft 14 Angular contact ball bearing 5 is arranged between the vertical shaft 14 and the gear sleeve 13, the axis of the vertical shaft 14 is parallel to the axis of the casing 6, the input end of the vertical shaft 14 is connected to the motor 7 through the reducer 8, and the output of the vertical shaft 14 The end is connected to the driving bevel gear 10, and the tail end of the vertical shaft 14 away from the driving bev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com