Tunnel boring machine

A technology for tunnel boring machines and tunnels, applied in the field of machinery, can solve the problems of high production costs, long design and manufacturing cycles of tunnel boring machines, and numerous parts, so as to achieve universality, shorten design and manufacturing cycles and production costs, and simplify design. and the effect of making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing.

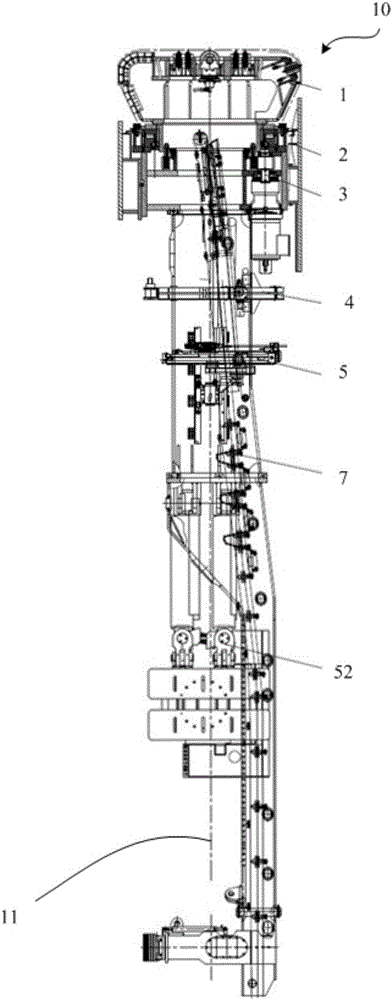

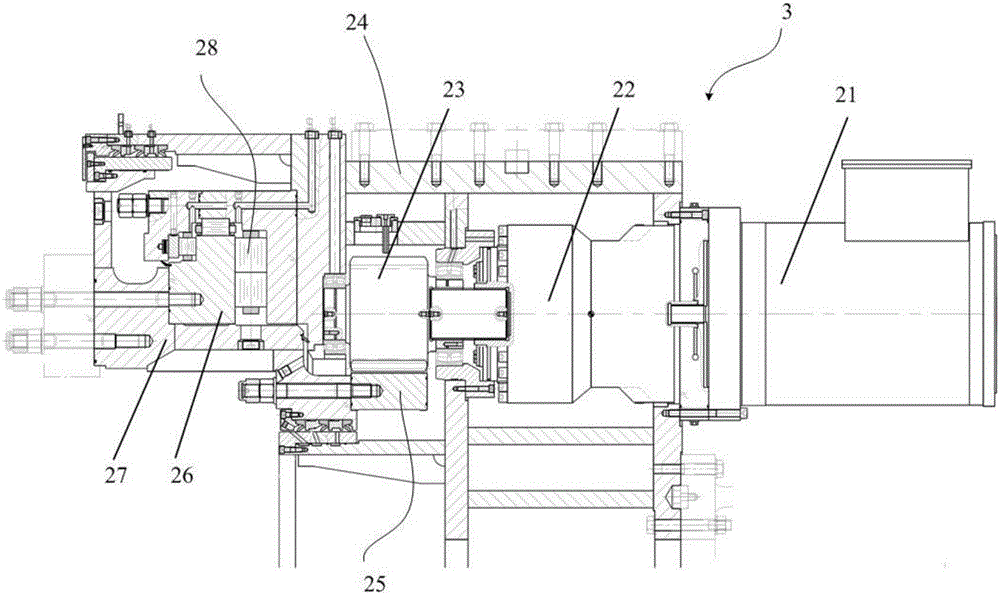

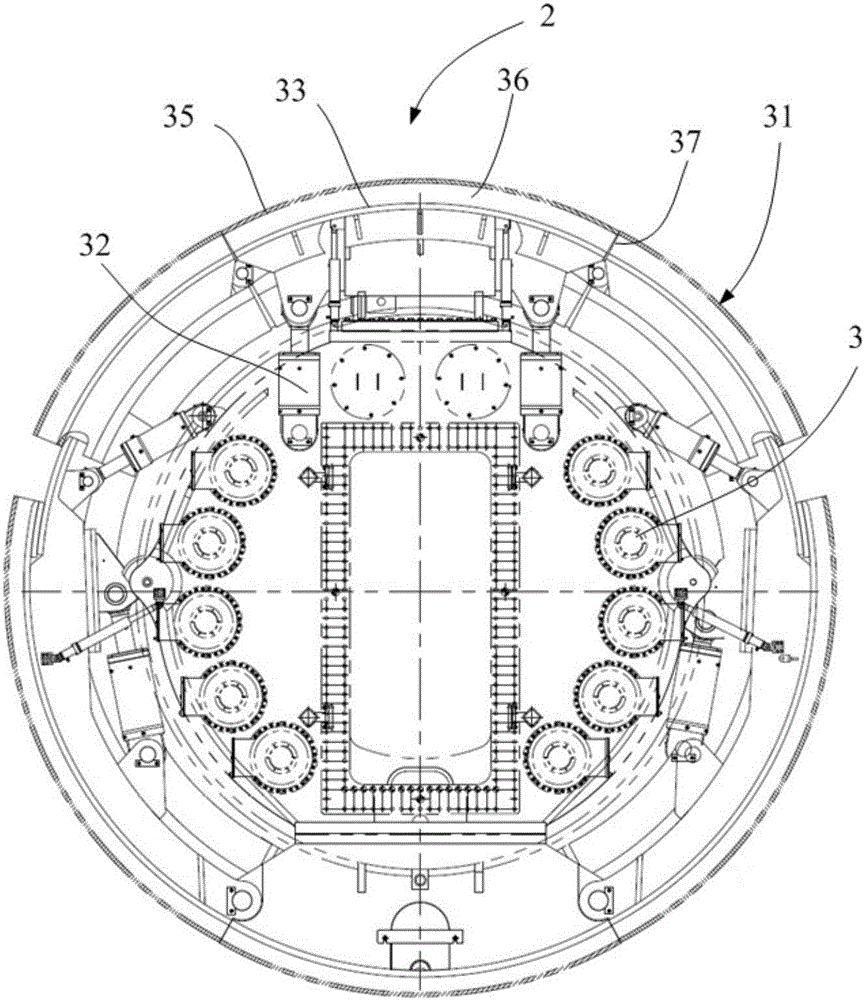

[0041] like figure 1 As shown, the tunnel boring machine 10 includes a cutter head 1 arranged along an axis 11, a shield 2, a main drive mechanism 3, a main beam 7 and multiple other structures or components arranged on the main beam 7, such as a steel arch installation mechanism 4 And bolter assembly 5.

[0042] The cutterhead 1 is at the forefront of the tunnel boring machine 10 and is used for drilling into the formation. The main driving mechanism 3 is used to apply driving force to the cutter head 1 . Shield 2 is used to initially support the tunnel walls of the tunnel that has just been drilled. The steel arch installation mechanism 4 adjacent to the shield 2 and arranged behind is used to support the tunnel. The bolter assembly 5 arranged behind the steel arch installation mechanism 4 is used to punch holes into the tunnel wall and insert reinforcements such as s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com