Auxiliary Steam Intermediate Pressure Cylinder Starting Method for Steam Turbine

A technology for assisting steam and steam turbines. It is used in the starting of engines, machines/engines, and mechanical equipment. It can solve the problems of low load adaptability, waste of manpower, and large equipment operation volume, and achieve improved safety, small life loss, Flexible start and stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

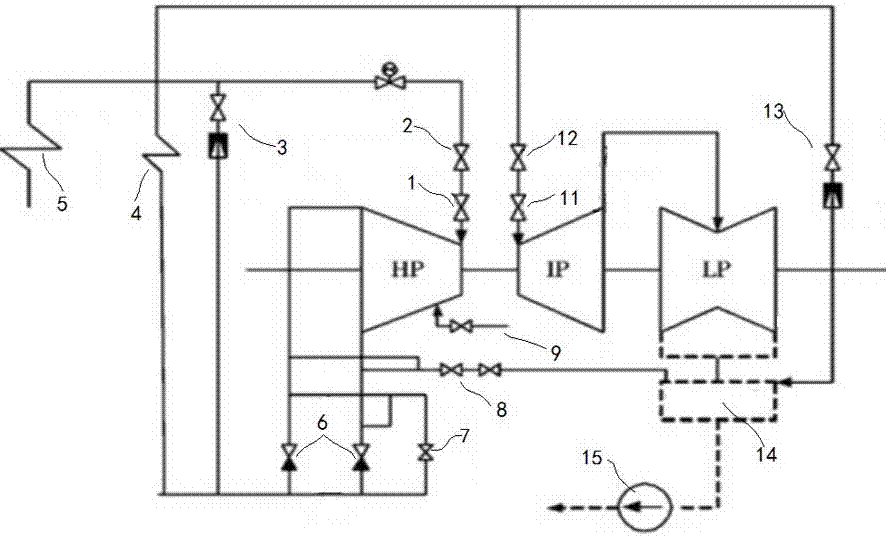

[0018] The present invention will be further explained below in conjunction with the accompanying drawings.

[0019] The steam turbine in this embodiment adopts Harbin Steam Turbine Co., Ltd. CLN350-24.2 / 566 / 566 supercritical, single-shaft, two-cylinder, two-exhaust, one-time intermediate reheat condensing steam turbine, and the unit is equipped with a 30% capacity two-stage simple bypass road system; the default start mode of the control system is the joint start of high and medium pressure cylinders.

[0020] like figure 1 As shown, the start-up system of the auxiliary steam medium-pressure cylinder of the steam turbine includes a high-pressure cylinder, a medium-pressure cylinder and a low-pressure cylinder. The pipeline where the check door (6) is located is connected in parallel with a heating pipeline for heating the high-pressure cylinder, and a heating valve (7) for controlling the heating speed is arranged on the heating pipeline; The pipeline behind the check door ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com