Production equipment, energy-saving production system and production method for melamine

A melamine and steam generator technology, applied in the chemical industry, can solve problems such as noise pollution, large power consumption, and increased urea consumption, and achieve the effects of efficient recycling, reduced investment costs, and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

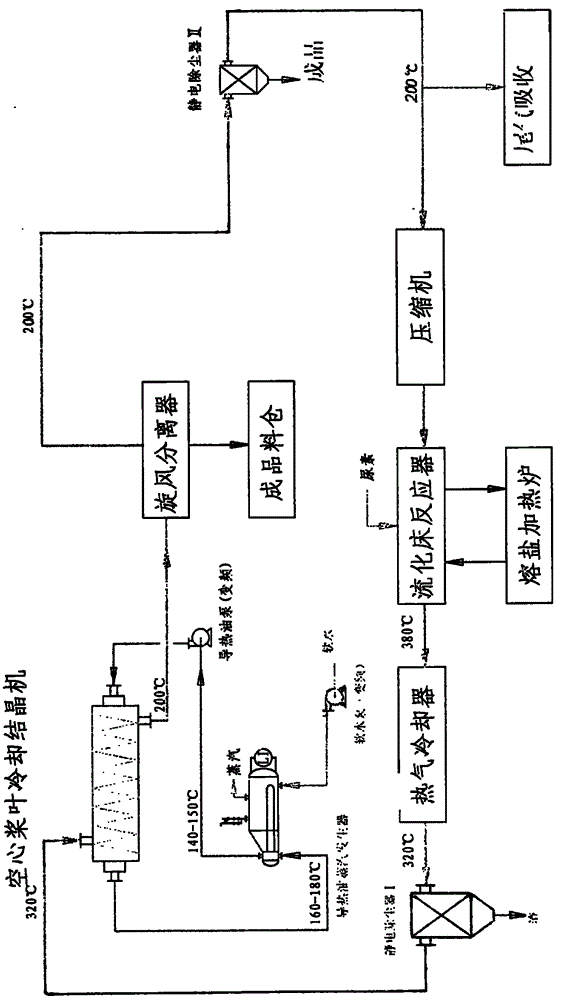

[0070] Refer to the attached Figure 4 and Figure 6 The embodiment of the forced crystallization energy-saving production system and the energy-saving combined production system of melamine heat-conducting oil is further described.

[0071] Such as Figure 4 , Figure 6 As shown, the melamine heat-conducting oil energy-saving production system of the present invention is mainly composed of a molten salt heating furnace, a fluidized bed reactor, a hot gas cooler, a hot gas purification device, a hot gas cooling crystallization system, a compressor and an exhaust gas absorption system; wherein the hot gas The purification device adopts the hot gas filter used in the traditional process. The above-mentioned hot gas cooling crystallization system is mainly composed of heat transfer oil hollow paddle cooling crystallizer, electrostatic precipitator, heat transfer oil steam generator and cyclone separator.

[0072] There are two construction methods for the structure of the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com