A super high temperature steam power cycle system using hydrogen injection combustion hybrid heating

A hybrid, hydrogen-injection technology, applied in the direction of steam engine devices, machines/engines, mechanical equipment, etc., to achieve the effects of shortened pipeline flow, flexible and simple start and stop, and improved power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

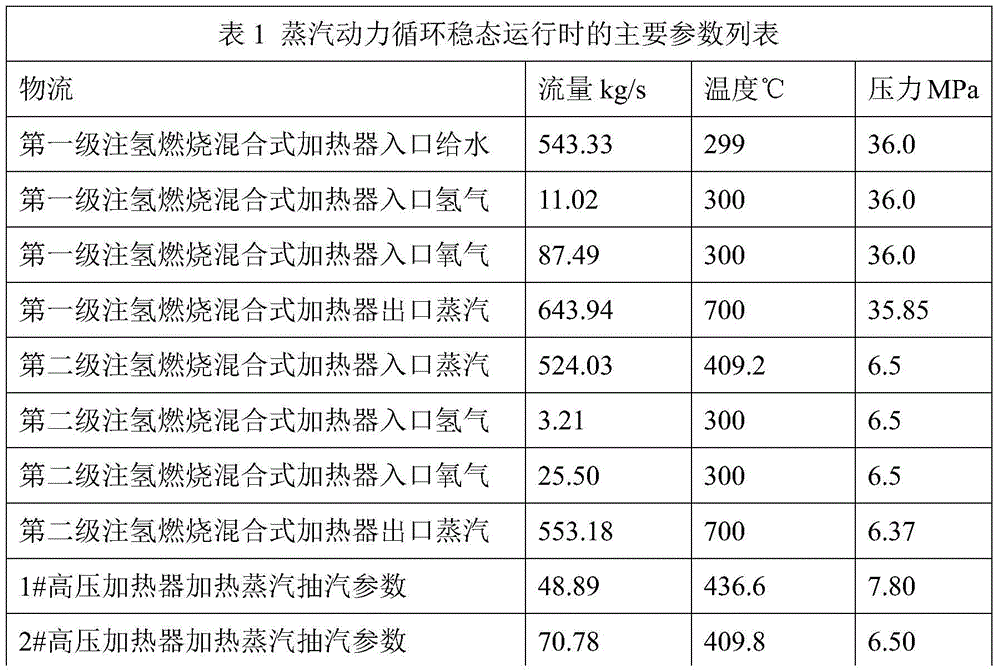

[0018] The present invention is described in detail below in conjunction with accompanying drawing and embodiment, and present embodiment is the generator set of 1000MW class.

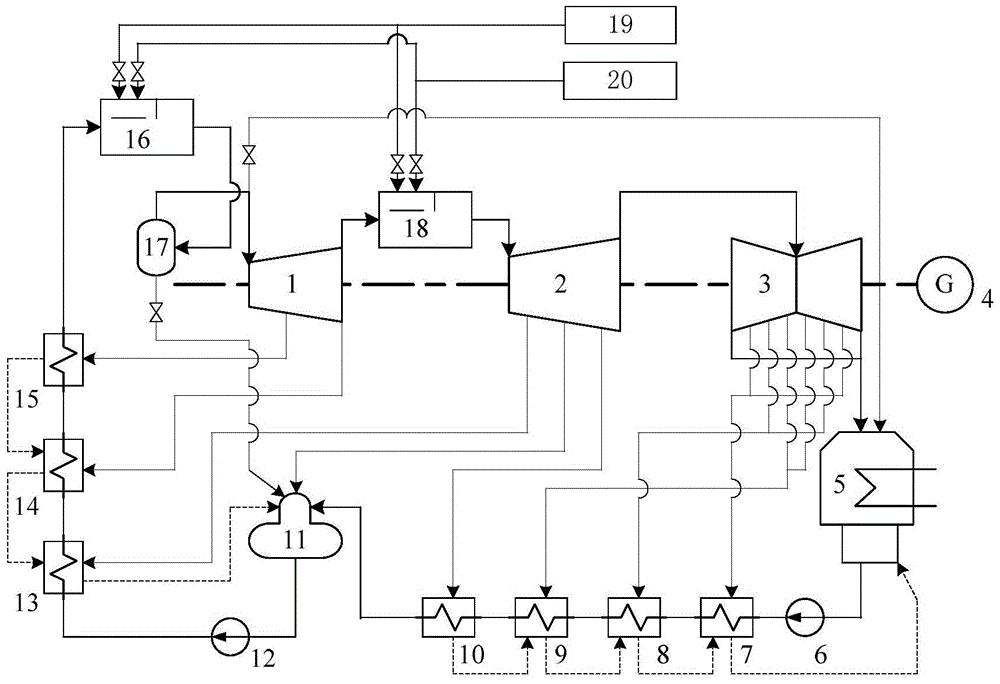

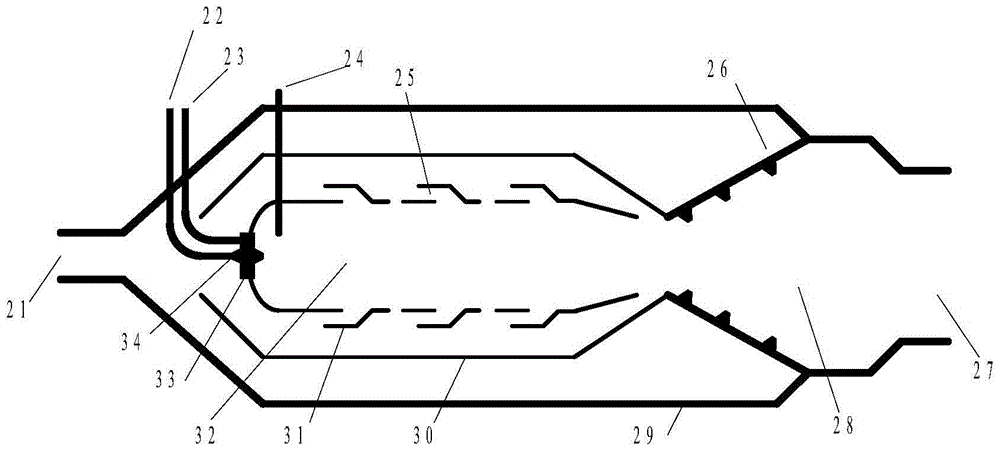

[0019] refer to figure 1, an ultra-high temperature steam power cycle system using hydrogen injection combustion hybrid heating, including a steam turbine high-pressure cylinder 1, a steam turbine high-pressure cylinder 1, a steam turbine medium-pressure cylinder 2, and a steam turbine low-pressure cylinder 3 arranged in series and coaxially and connected to a generator 4 , to drive the generator 4 to generate electricity, the steam turbine high-pressure cylinder 1 outlet is connected to the steam inlet of the second-stage hydrogen injection combustion hybrid heater 18, and the second-stage hydrogen injection combustion hybrid heater 18 steam outlet is connected to the steam turbine medium-pressure cylinder 2 steam inlet , the steam outlet of medium-pressure cylinder 2 of the steam turbine is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com