Pre-sealing structure

A technology for structural parts and graphite rings, which is used in the lubrication of jet propulsion units, turbine/propulsion units, engine components, etc. Sealing effect, good sealing effect, friction reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the examples, the following examples are explanations of the present invention and the present invention is not limited to the following examples.

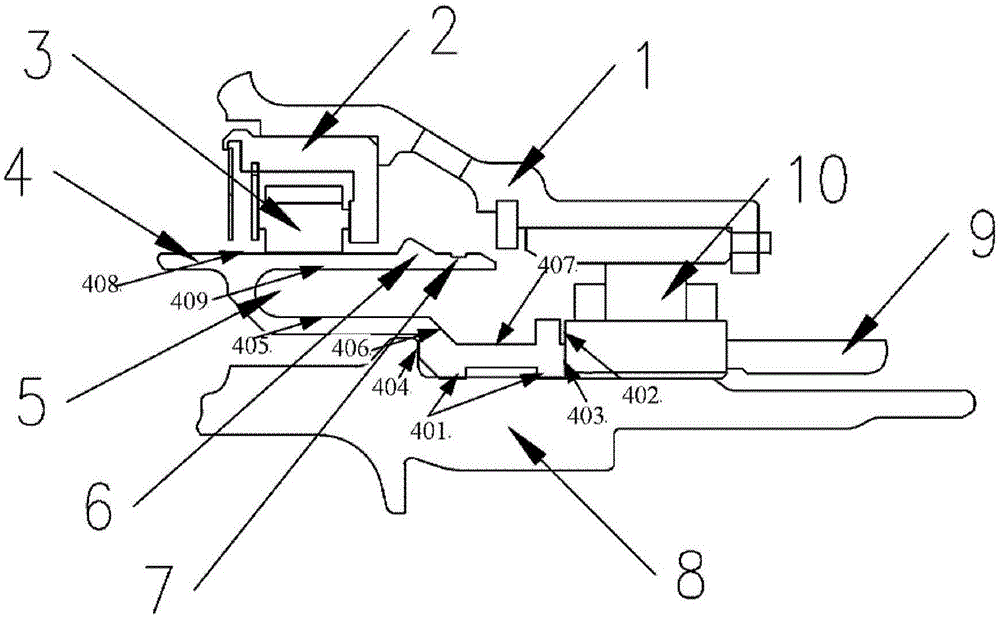

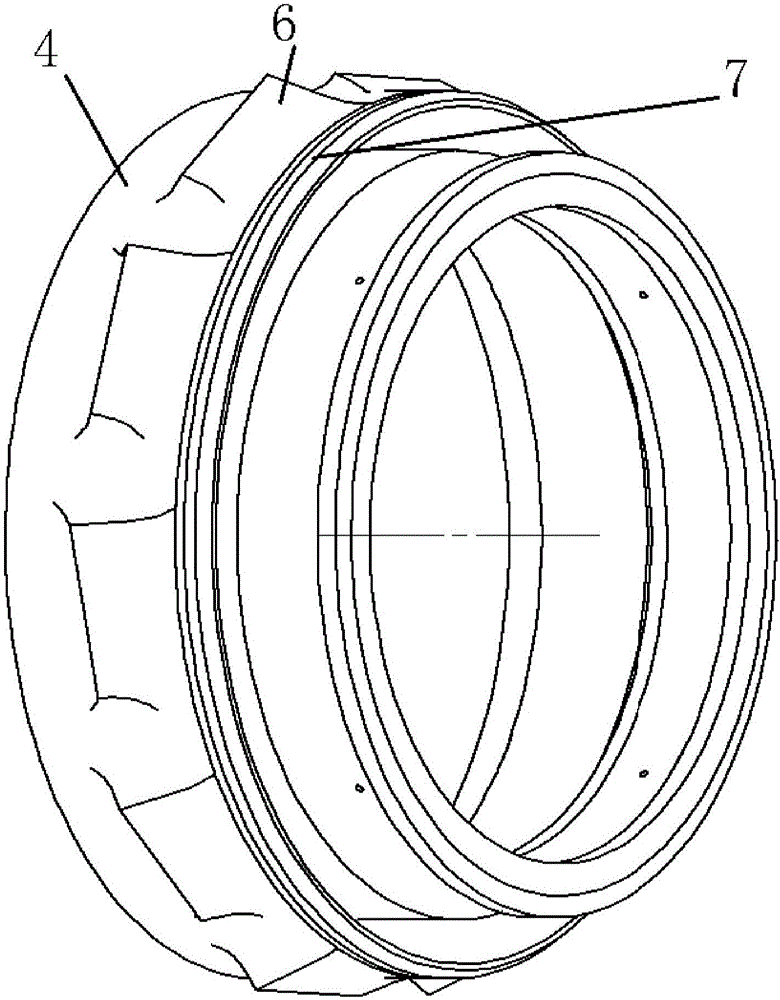

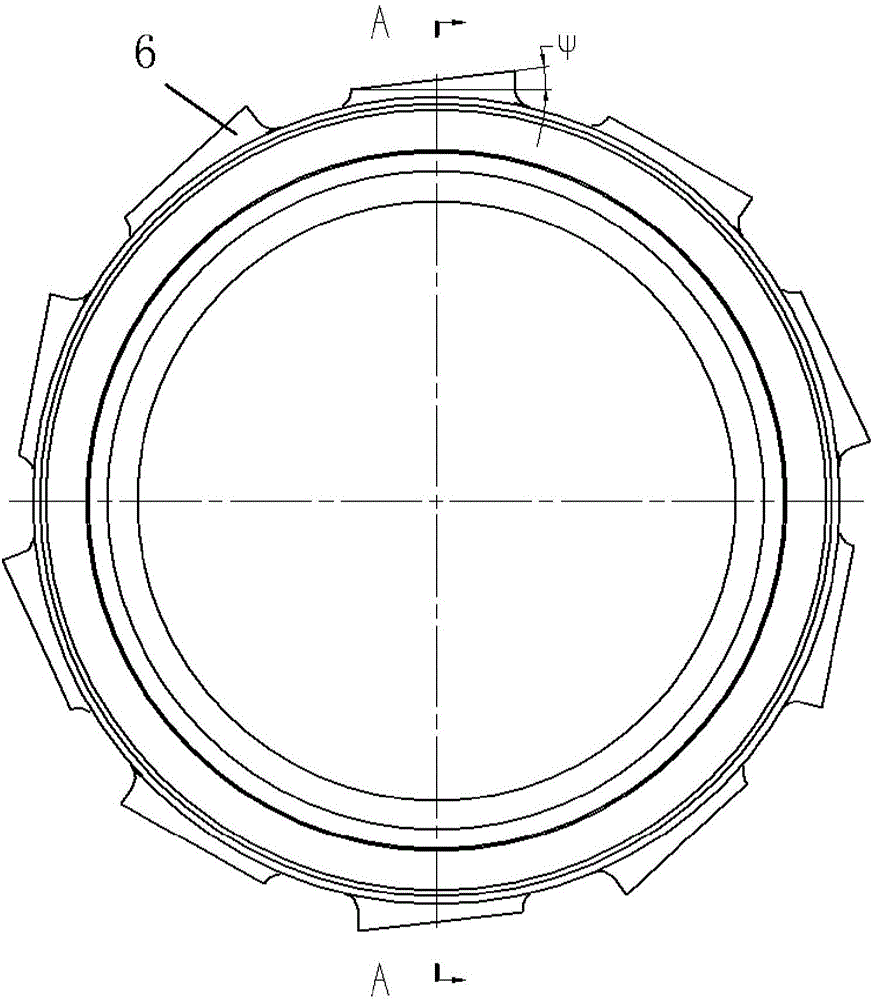

[0029] The invention discloses a graphite ring runway sealing structure used for sealing a bearing cavity, which can be applied in the fields of ground gas turbines, aeroengines and the like. On the runway with a graphite ring for sealing the bearing cavity, an oil cut-off groove and an oil thrower are designed on the side of the working face of the runway (near the side of the bearing cavity). This graphite ring runway pre-seal structure uses the oil cut-off groove to avoid the accumulation of lubricating oil in the bearing cavity, and at the same time uses the oil thrower next to the oil cut-off groove to further throw the lubricating oil droplets that may flow into the sealing surface of the graphite ring back to the bearing through the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com