Waste oil collection device for yaw system of wind turbine generator

A yaw system and waste oil collection technology, applied in the field of wind power, can solve the problems of aggravated oil pollution on the yaw platform, failure to fully collect the oil collection box, and excessive accumulation of yaw lubricating grease, so as to improve maintenance efficiency and facilitate Post-maintenance and hygienic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

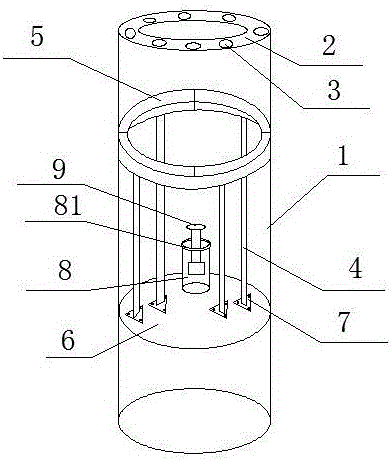

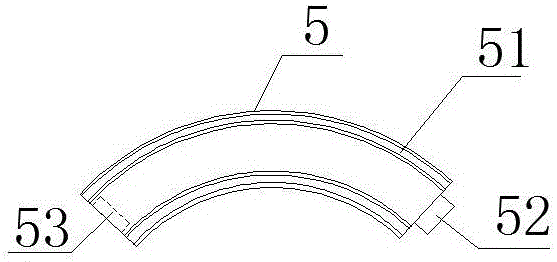

[0021] figure 1 , figure 2 , image 3 and Figure 4 A specific embodiment of the present invention is shown: a wind turbine yaw system waste oil collection device, including a tower 1 and a yaw brake disc 2 arranged on the upper end of the tower 1, the inner wall of the tower 1 is provided with a yaw platform 6. The yaw platform 6 is provided with four brackets 4 upward, and the upper ends of the four brackets 4 are all provided with arc-shaped grooves 5, and the four arc-shaped grooves 5 are sequentially connected end to end to form an annular oil collection tank. The yaw brake The disk 2 is provided with several oil leakage holes 3 along its circumferential direction, and the annular oil collection groove is arranged directly below the oil leakage holes 3 .

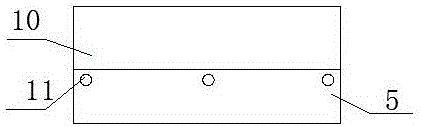

[0022] In this embodiment, the inner and outer sides of the arc-shaped groove 5 are provided with heightened edges 10, the height of the heightened edges 10 is 3 cm, and the heightened edges 10 can avoid waste oil s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com