Oil well pump draining liquid by opening valve balls

A ball and oil well pump technology, which is applied in the field of oil well oil well pumps, can solve problems such as non-drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

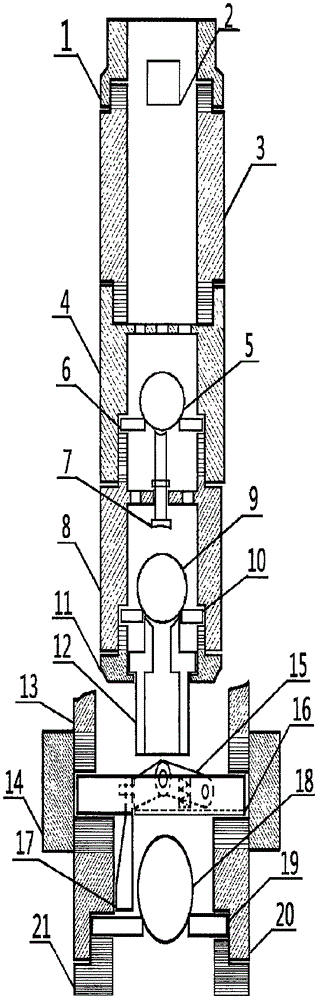

[0043] Such as figure 1 As shown, a kind of oil well oil well pump that opens the valve valve, the lower end of the pump is a fixed support seat 21, in order to fix the sealing of the valve seat 19, the fixed support seat 21 is connected with the valve sleeve 20 with a screw thread, and the fixed valve Seat 19 is compressed, and described fixed valve seat 19 and fixed valve ball 18 are contacted and sealed, and fixed valve ball 18 is limited in the valve sleeve.

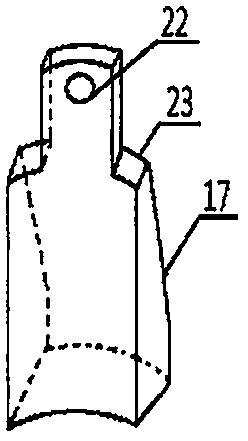

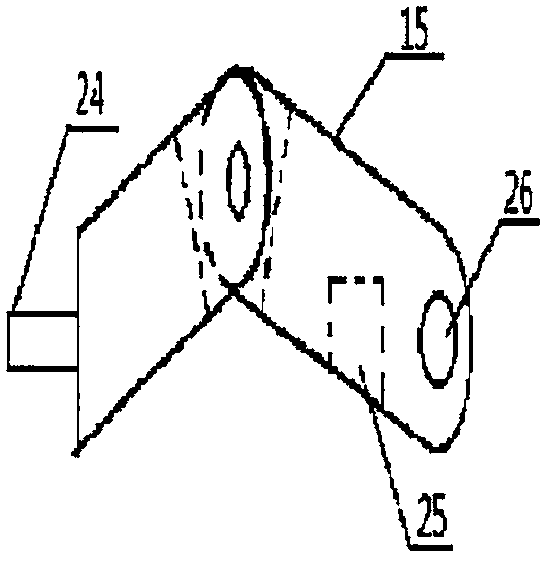

[0044] Such as figure 1 , figure 2 , image 3, Figure 4 , Figure 7 As shown, the ball dial 17 is loaded between the fixed valve ball 18 and the sleeve 20, the ball dial 17 has a certain activity space, and the ball dial 17 is sleeved on the board mouth 30 through the valve cover 16. On the hanging plate post 24 of the movable joint push rod 15, the ball dialing plate 17 is provided with an anti-stalking step 23 on it.

[0045] Such as figure 1 , image 3 , Figure 5 , Figure 6 As shown, the movable mand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com