Novel pressure stabilization overflow valve

An overflow valve and voltage stabilization technology, applied in the field of hydraulic control, can solve the problems of pressure fluctuations at the back end of the voltage stabilization device, complex structure, and large space occupation, so as to improve shift performance, overcome complex structure, and small pressure drop Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The working principles and embodiments of the present invention will be described in detail below in conjunction with the attached structural diagrams, but the details of the structural diagrams and embodiments are not intended to limit the present invention, and any use of the working principles of the present invention should belong to the protection scope of the present invention.

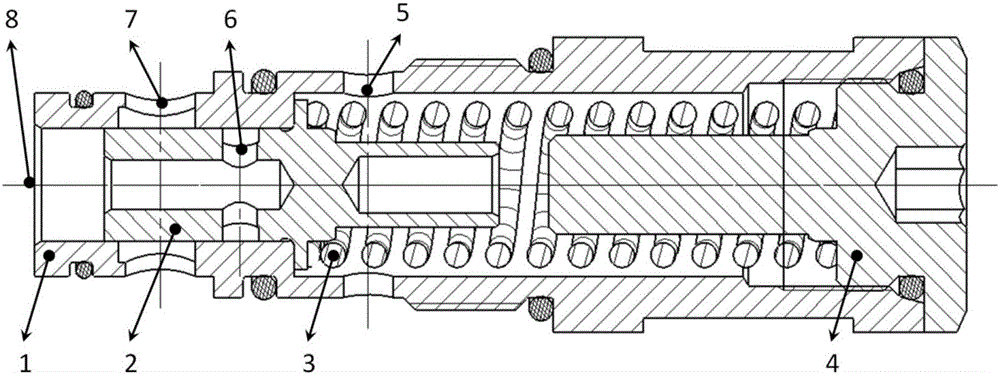

[0011] figure 1 The structure diagram of the pressure-stabilizing relief valve mainly used in the hydraulic control system of automatic transmission provided by the present invention is composed of valve sleeve 1, spool 2, spring 3, and limit plug 4. The spool 2 has a limit convex After being installed in the valve sleeve 1, it can only move in one direction (the opening direction of the valve port). The centering structure of the spring 3 is arranged on the valve core 2 and the limit plug 4, and a limit rod is designed on the limit plug 4 to limit the maximum stroke of the valve core and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com